2525

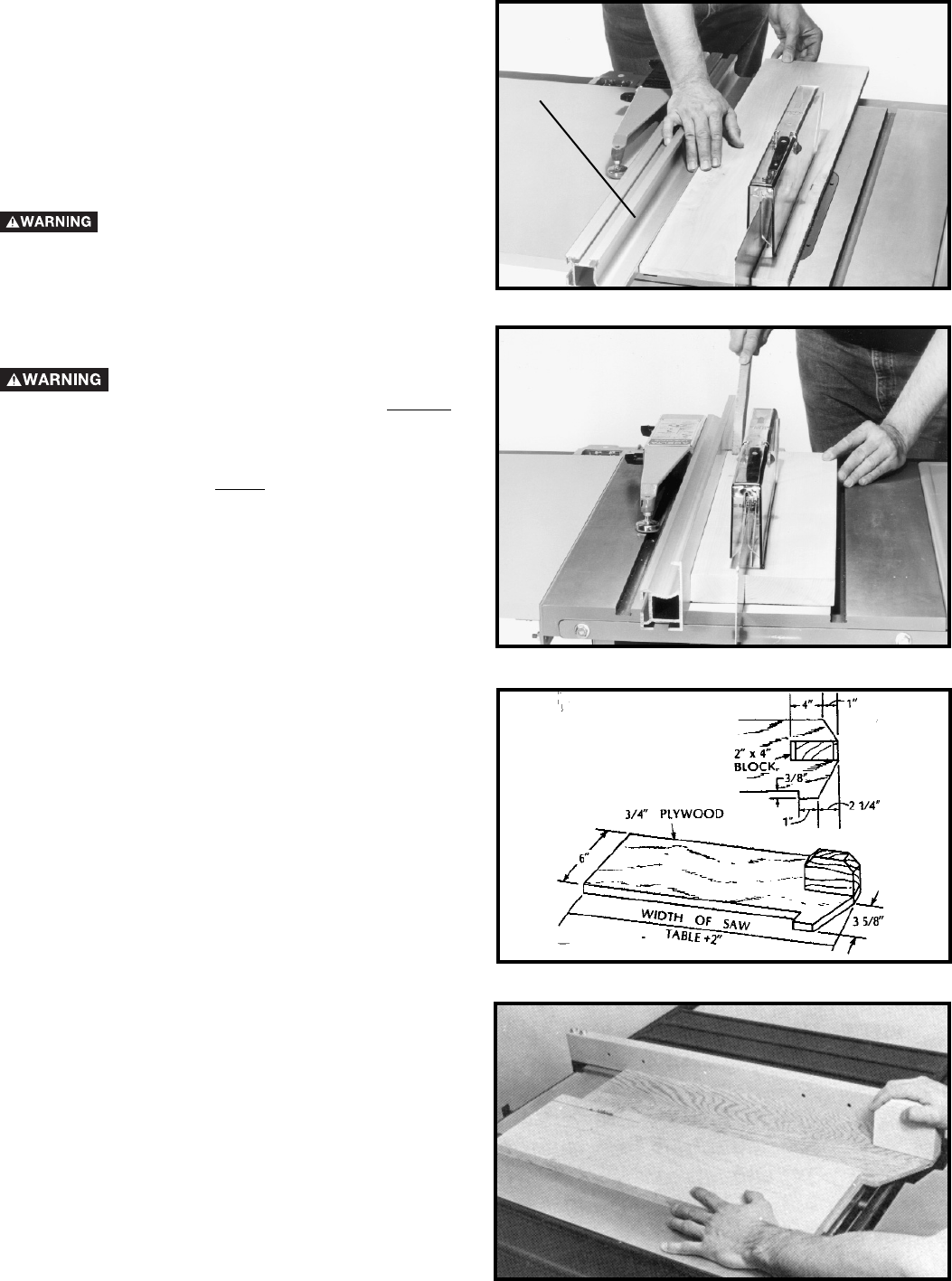

Fig. 55

Fig. 55A

A

Fig. 56

Ripping is cutting lengthwise through a board, (Fig. 55).

NOTE: Be sure the material to be cut is seasoned, dry

and flat. The rip fence (A) is used to position and guide

the work. One edge of the work rides against the rip

fence while the flat side of the board rests on the table.

Since the work is pushed along the fence, it must have

a straight edge and make solid contact with the table.

THE SAW BLADE GUARD MUST BE

USED. ON DELTA SAWS, THE GUARD HAS ANTI-

KICKBACK FINGERS TO PREVENT KICKBACK AND

A SPLITTER TO PREVENT THE WOOD KERF FROM

CLOSING AND BINDING THE BLADE. BE SURE TO

REPLACE OR SHARPEN THE ANTI-KICKBACK

DEVICES WHEN THE POINTS BECOME DULL.

A RIP FENCE SHOULD ALWAYS BE

USED FOR RIPPING OPERATIONS. NEVER

PERFORM A RIPPING OPERATION FREE-HAND.

1. Start the motor and advance the work holding it down

and against the fence. Never stand in the line of the

saw cut when ripping. When the rip width is 6 inches

or wider, hold the work with both hands and push it

along the fence and into the saw blade (Fig. 55). The

work should then be fed through the saw blade with

the right hand. Only use the left hand to guide the

workpiece. Do not feed the workpiece with the left

hand. After the work is beyond the saw blade and

anti-kickback fingers, remove hands from the work.

2. When this is done the work will either stay on the

table, tilt up slightly and be caught by the end of the

rear guard, or slide off the table to the floor.

Alternately, the feed can continue to the end of the

table, after which the work is lifted and brought

along the outside edge of the fence. The cut-off

stock remains on the table and is not touched until

the saw blade has stopped, unless it is a large piece

allowing safe removal. When ripping boards longer

than three feet, use a work support at the rear of the

saw to keep the workpiece from falling off the saw

table.

3. If the ripped work is less than 6 inches wide, a push

stick should always be used to complete the feed, as

shown in Fig. 55A. The push stick can easily be

made from scrap material as explained in the section

“CONSTRUCTING A PUSH STICK.”

4. Ripping narrow pieces can be dangerous if not done

carefully. Narrow pieces usually cannot be cut with

the guard in position. If the workpiece is short

enough, use a pushboard. When ripping material

under 2 inches in width, a flat pushboard is a

valuable accessory since ordinary type sticks may

interfere with the blade guard. When using a

pushboard, the width of the pushboard must be

added to the width of the rip fence position setting. A

flat pushboard can be constructed as shown in Fig.

56 and should be used as shown in Fig. 57.

NOTE: Some special operations (when using the

moulding cutterhead) require the addition of an

auxiliary wood facing to the fence, as explained in

the section “USING AUXILIARY WOOD FACING”

and use of a push stick.

RIPPING

Fig. 57