9

Never attempt to change direction of rotation while the switch

is “ON”. To do so, may damage interlock feature built into

switch. Be sure that the switch is “OFF” and the motor has

completely stopped before changing the direction of rotation.

4. VARIABLE SPEED – As the trigger switch is squeezed, the tool speed

increases.

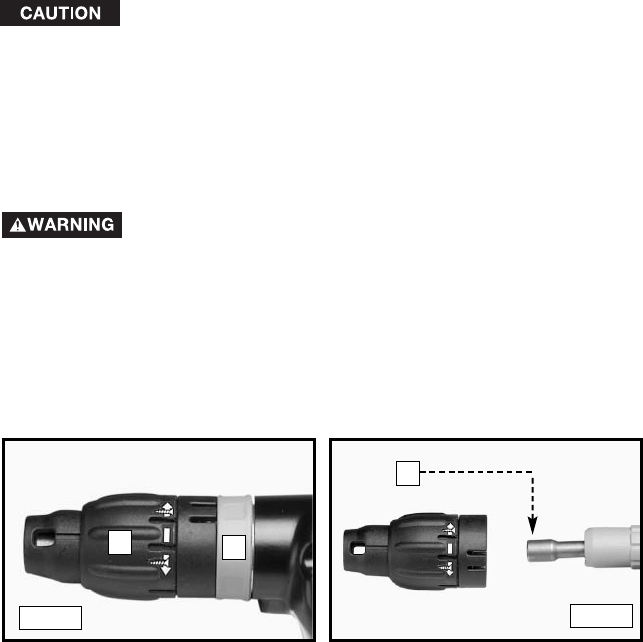

1. Pull the Depth Stop Assembly (A) Fig. 2 from the clutch housing (B).

2. Pull the nutsetter (C) Fig. 3 straight out. If it is difficult to remove, grip it with

pliers and pull.

3. Push the nutsetter into the screwdriver spindle until the ball in the spindle

snaps into the groove in the nutsetter shank.

4. Replace the depth stop assembly and adjust for depth of drive (see

“ADJUST DEPTH STOP, MODEL 4640”).

DISCONNECT TOOL FROM POWER SOURCE.

A

B

C

Fig. 2

Fig. 3

ADJUST DEPTH STOP – MODEL 4640

1. Turn the adjusting collar (A) Fig. 2 until the end of the depth stop is flush with

the end of the nutsetter. Do not push the nutsetter in. This will engage the

internal drive.

2. Drive a test fastener into a piece of scrap material identical to the workpiece.

Examine the results of the drive and make any necessary depth stop

adjustments.

a) To increase the depth of drive, repeat STEP 1 and turn the adjusting

collar so that the end of the nutsetter extends beyond the end of the

depth stop.

b) To decrease the depth of drive, repeat STEP 1 and turn the adjusting

collar so that the end of the depth stop extends beyond the end of the

nutsetter.

Each click of the adjusting collar results in .007" change in the depth of drive.

3. Repeat STEPS 1 and 2 until the desired result is obtained.

TO CHANGE HEX NUTSETTER – MODEL 4640