6

3. Clean and insert smooth end of bit as far as it will go into the chuck, then

withdraw bit approximately

1

/16", or up to the flutes for small bits.

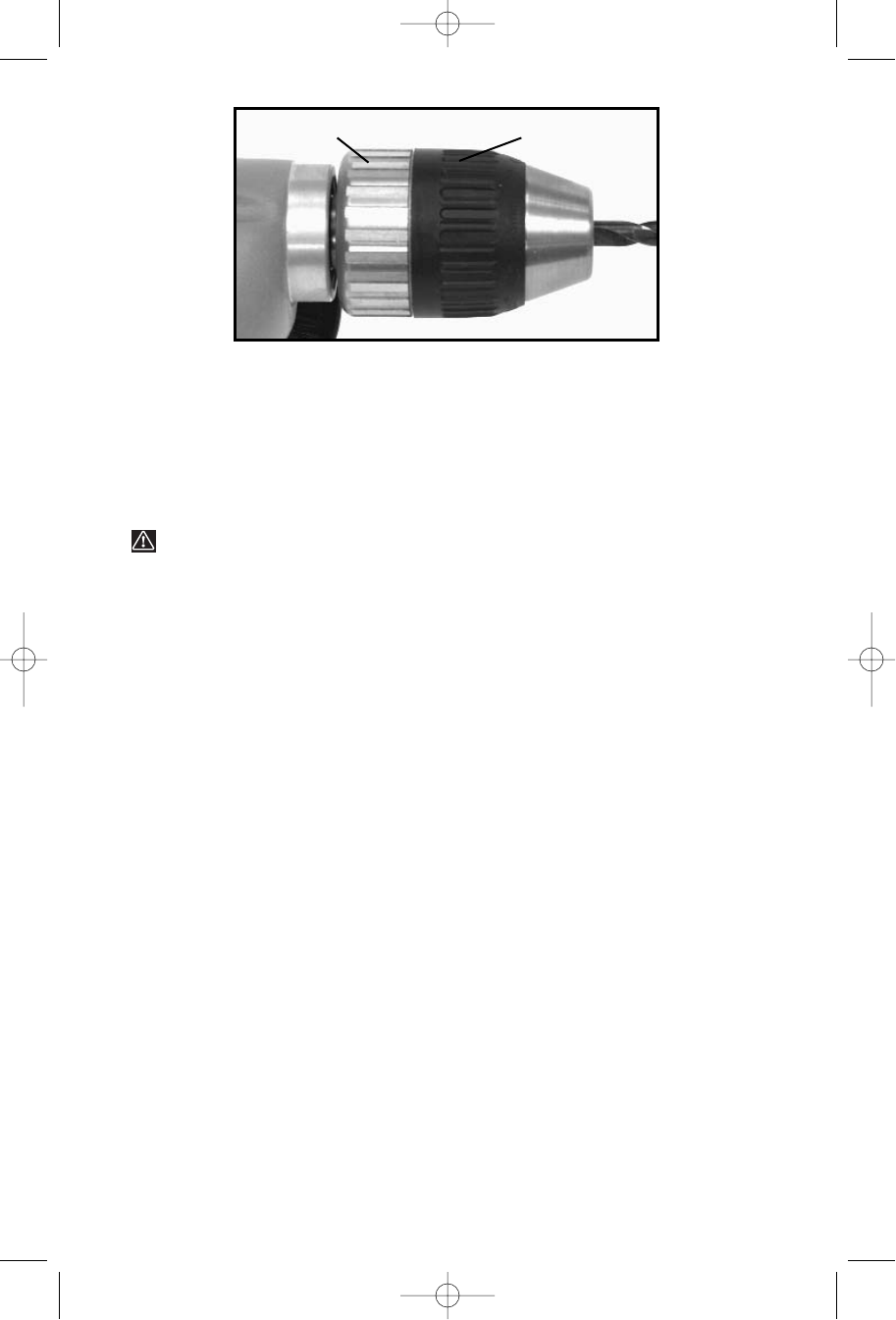

4. While holding the bit with one hand, turn outer sleeve (A) Fig. 2, clockwise

until the bit is gripped in the chuck.

5. Tighten chuck by holding chuck ring (B) Fig. 2, with one hand while

turning outer sleeve (A) clockwise with other hand. Tighten securely.

WARNING: Do not operate drill motor while installing or removing

bits. Operating drill motor can cause bit to be thrown from chuck

causing personal injury.

6. To remove bit, reverse foregoing procedure.

TO INSTALL AUXILIARY HANDLE

An auxiliary handle is supplied with some models. This handle screws directly

into the drill housing providing complete control of the drill.

It is strongly recommended that the auxiliary handle be used and tool held as

illustrated in Fig. 4 during all drilling operations.

TO START AND STOP DRILL

1. Make sure drill switch is “OFF”. Make sure power circuit voltage is the

same as that shown on the specification plate of the drill. Connect drill to

power circuit.

2. Squeeze TRIGGER SWITCH (Fig. 3) to start motor. Release trigger to stop

motor.

3. LOCK BUTTON – A lock button (Fig. 3) is provided to keep motor running

without holding the trigger switch ON.

TO LOCK the trigger switch ON, squeeze the trigger as far as it will go, push

in lock button and release trigger.

TO UNLOCK lock button, squeeze trigger and release, leaving lock button free

to spring out.

NOTE: The lock button can be engaged only when the drill is running

at maximum speed.

CAUTION: NEVER USE THE LOCK BUTTON WHERE DRILL MAY

HAVE TO BE STOPPED SUDDENLY.

Fig. 2

AB

901013 - 12-31-01.qxd 2/11/02 3:01 PM Page 6