9

CAUTION: DO NOT EXERT PRESSURE ON SCREW WHILE DOING THIS.

4. Place end of screw in desired location and remove fingers.

5. Apply forward pressure to drive screw until depth stop rests on the

surface of the work. The depth stop should be adjusted so the fastener head

seats firmly on the work. Avoid seating the fastener too deep to prevent

shearing off the head.

TO REMOVE SCREWS – ALL MODELS

1. Install proper bit that fits screw.

2. Set screwdriver for reverse rotation.

3. Start screwdriver and place bit in screw.

4. Exert forward pressure to remove screw.

MAINTENANCE

KEEP TOOL CLEAN

Periodically blow out all air passages with dry, compressed air. All plastic parts

should be cleaned with soft damp cloth. NEVER use solvents, to clean plastic

parts. They could possibly dissolve or otherwise damage the material.

CAUTION: Wear safety glasses while performing this operation.

FAILURE TO START

Should your tool fail to start, check to make sure the prongs on the cord plug

are making good contact in the outlet. Also, check for blown fuses or open

circuit breakers in the line.

CHECK CLUTCH CONDITION

CAUTION: DISCONNECT TOOL FROM POWER SOURCE

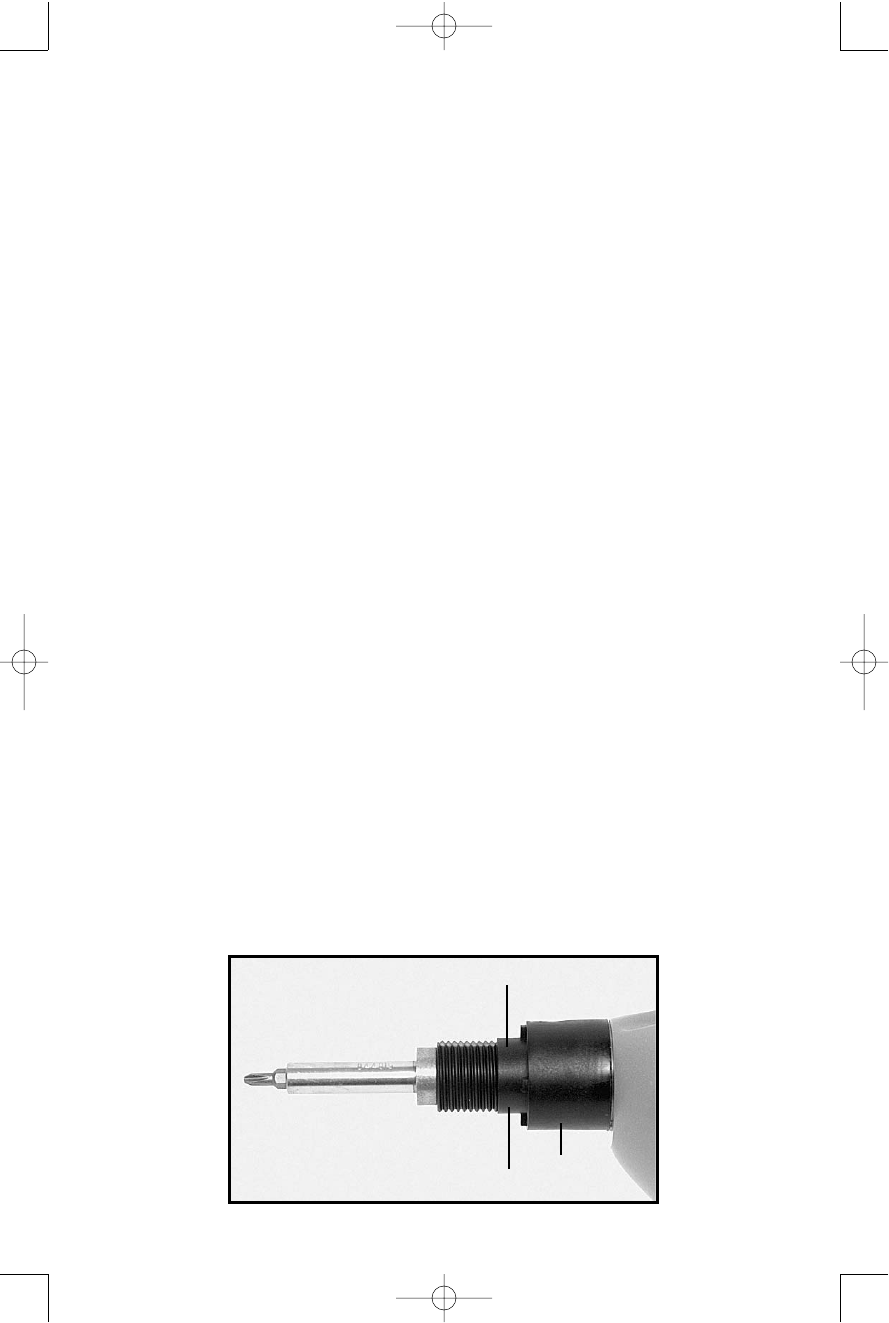

Periodically, depending on use, screwdriver clutch jaws should be inspected

for wear. This may be done by removing the screwdriver mechanism housing

(A), Fig. 5, from the power unit.

NOTES: The clutch housing is attached to the power unit with left-

hand threads. The depth stop assembly may be removed from the

clutch housing to expose a set of wrenching “flats” (B), Fig. 5, on the

clutch housing. These “flats” permit the use of a wrench to aid in

clutch housing removal.

Fig. 5

B

B

A

902387 - 10-31-01.qxd 2/12/02 3:30 PM Page 9