16

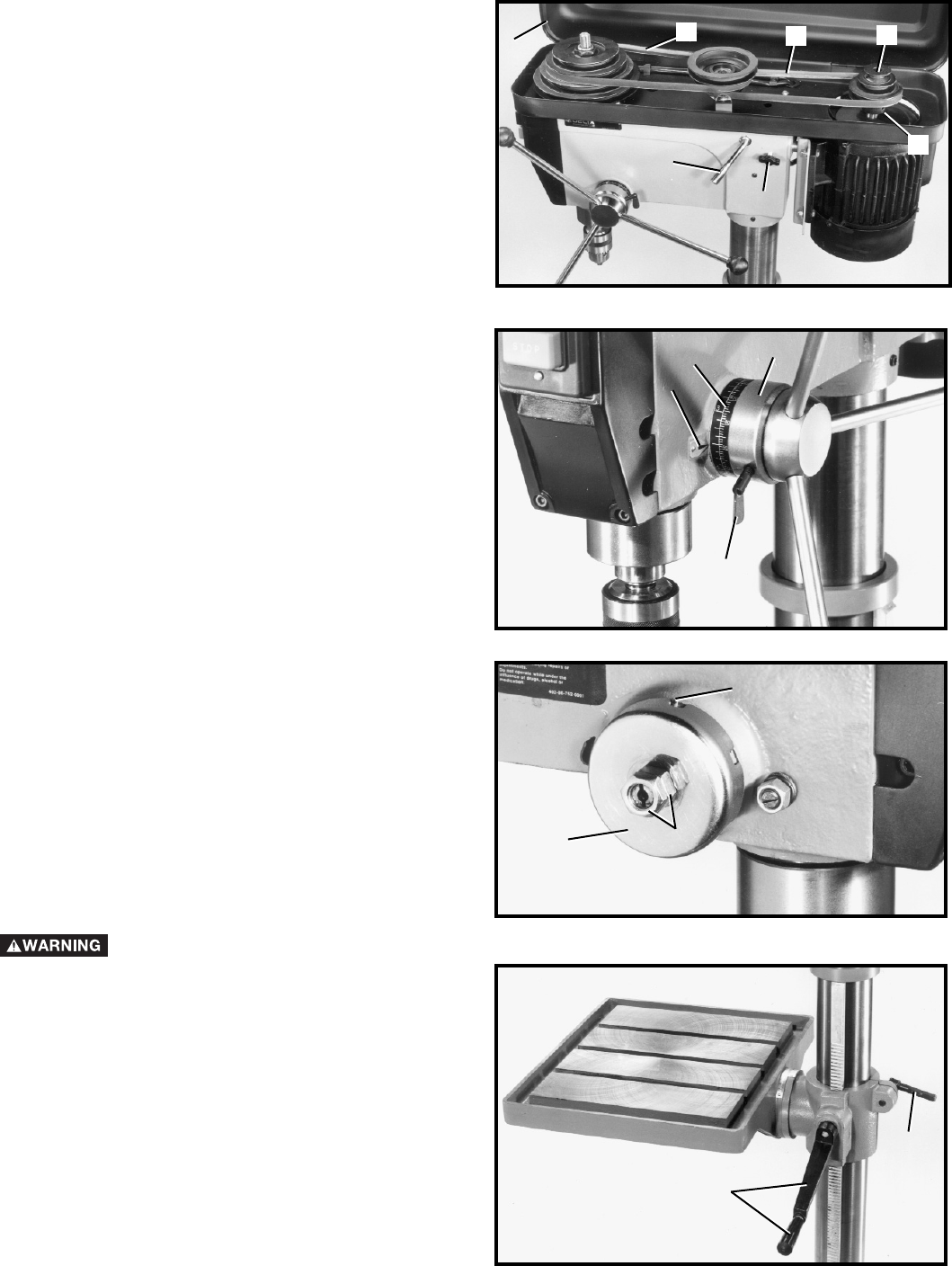

Fig. 27

Fig. 28

Fig. 29

DRILLING HOLES TO DEPTH

Where a number of holes are to be drilled to exactly the

same depth, a depth stop is provided in the pinion shaft

housing (A) Fig. 27, and is used as follows:

1. Loosen lock lever (B) Fig. 27, and rotate housing (A)

until the pointer (C) lines up with the depth indicated on

the English/Metric scale (D) that you want the spindle to

lower. Then tighten lock lever (B).

2. The spindle will then lower to the exact depth as

indicated on the scale (D) Fig. 27

ADJUSTING SPINDLE

RETURN SPRING

For the purpose of automatically returning the spindle

upward after a hole has been drilled, a spindle return

spring is provided in the spring housing (A) Fig. 28. This

spring has been properly adjusted at the factory and

should not be disturbed unless absolutely necessary. To

adjust the return spring, proceed as follows:

DISCONNECT MACHINE FROM THE

POWER SOURCE.

1. Loosen the two nuts (B) Fig. 28, approximately one-

quarter inch. IMPORTANT: DO NOT REMOVE NUTS

(B) FROM SHAFT.

2. While FIRMLY holding spring housing (A) Fig. 28,

pull out housing and rotate it until the roll pin (C) is

engaged with the next notch on the housing. Turn the

housing counterclockwise to increase and clockwise to

decrease spring tension. Then tighten the two nuts (B)

to hold the housing in place. IMPORTANT: NUTS (B)

SHOULD NOT CONTACT SPRING HOUSING (A) WHEN

TIGHT.

B

C

A

D

B

A

C

B

A

Fig. 26

A

C

B

D

D

E

F

5. After the belts (D) Fig. 26, are positioned on the

desired steps of the motor, center and spindle pulleys,

move tension lever (C) to the rear until the belts (D) are

properly tensioned and tighten the two tension lock

knobs (B). The belts (D) should be just tight enough to

prevent slipping. Excessive tension will reduce the life of

the belts, pulleys and bearings. Correct tension is

obtained when the belts (D) can be flexed about 1″ out

of line midway between the pulleys using light finger

pressure.