7

WHICH BLADE TO USE

In general, select a blade which will allow at least two teeth to be engaged in

the material thickness. The thinner or the harder the material, the finer the

blade teeth. The thicker or the softer the material, the coarser the blade teeth.

The hi-speed steel blades stay sharp longer than alloy steel blades.

USE OF LUBRICANTS

NEVER USE LIQUID COOLANT WITH YOUR BAND SAW. Damage to the

blade guide bearings or rubber tires on the pulleys may result.

WARNING: LIQUID COOLANTS CAN INCREASE THE RISK OF

ELECTRIC SHOCK. Use only stick wax to lubricate the blade.

Porter-Cable’s “Lube Wax” is available as an accessory and is recommended

when cutting aluminum, brass and thick materials. Cast iron should be cut dry.

With the saw running, apply the wax momentarily to both sides of the blade.

Reapply wax intermittently as needed.

WARNING: EXERCISE EXTREME CARE TO PREVENT HANDS

FROM CONTACTING THE BLADE.

After prolonged cutting, the wax will cling to the pulleys of your BAND SAW.

This does not affect the operation of the machine. All that is necessary is to

disconnect the machine from the power source and wipe the wax from the

pulleys.

ASSEMBLY

TO CHANGE SAW BLADES

CAUTION: DISCONNECT TOOL FROM POWER SOURCE.

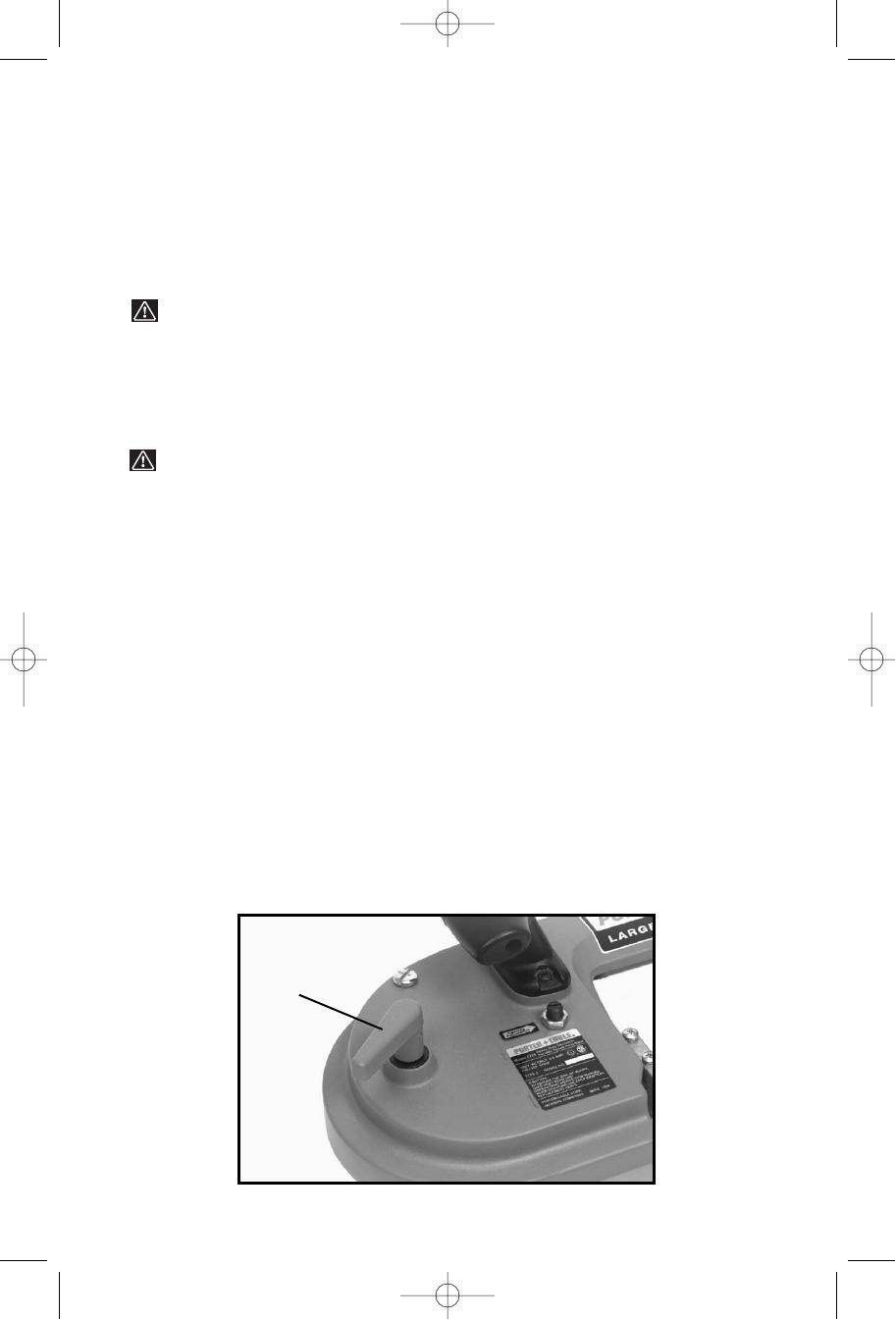

TO REMOVE BLADE – Turn handle (A), Fig. 2, clockwise to release tension on

the saw blade. Remove the blade, first from the pulleys and then from the

blade guide.

Before installing a blade, clean chips and wax, which may have accumulated

on blade guides and pulley tires. TO INSTALL BLADE – install blade in blade

guides and then position on pulleys. MAKE SURE TEETH ON LEFT SIDE OF

MACHINE POINT TOWARD THE REAR OF THE MACHINE. See Fig. 3.

Turn handle (A), Fig. 2, counterclockwise as far as it will go. This places tension

on saw blade.

Start and stop saw two or three times to seat blade on pulleys.

Fig. 2

A

902452 - 03-08-02.qxd 3/18/02 9:02 AM Page 7