12

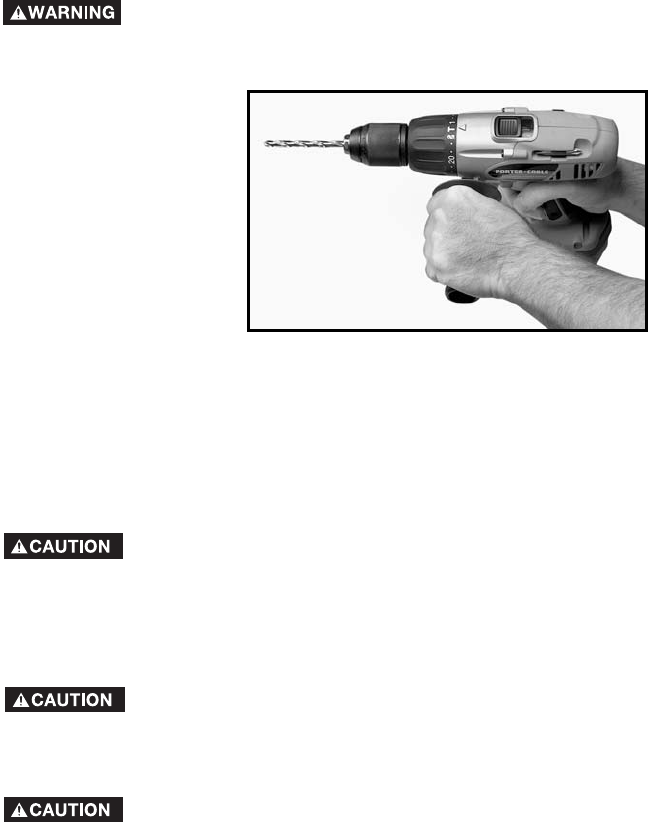

HOW TO HOLD THE HAMMER DRILL/DRIVER

The front end of the Hammer Drill/Driver may be made live

if the tool drills into live wiring in the wall. TO PREVENT

ELECTRICAL SHOCK, THE HAMMER DRILL/DRIVER

MUST BE HELD AS SHOWN IN FIG. 10B.

GENERAL DRILLING

1. Set torque adjusting collar for drilling operation and set speed selector to

appropriate speed.

2. Be sure drill bit is securely gripped in chuck.

3. Set REVERSING BUTTON for clockwise rotation.

Make sure work is held securely in vise or clamped in place

prior to starting drilling operation. Loose work may spin and

cause bodily injury.

4. Locate exact center for hole to be drilled, and use a center punch to make

a small dent in work.

5. Place tip of drill bit in dent made by center punch, hold drill square with

work, and start the motor.

Applying too much pressure may cause the bit to overheat or

break resulting in bodily injury or damaged drill bits.

Apply steady, even pressure to keep drill bit cutting. Too little pressure will keep

the bit from cutting and dull the cutting edges due to excessive friction created

by sliding over the surface.

Always be alert and brace yourself against the twisting action

of the drill.

6. If drill stalls or becomes jammed in the hole, release trigger immediately,

remove drill bit from work, and determine cause of stalling or jamming. DO

NOT SQUEEZE TRIGGER ON AND OFF IN AN ATTEMPT TO FREE A STALLED

OR JAMMED DRILL – THIS WILL DAMAGE THE MOTOR.

The direction of rotation may be reversed to help free a jammed bit. Be sure

direction of rotation is RESET before attempting to continue drilling.

7. Reduce the pressure on the drill just before the bit cuts through the work

to avoid splintering wood or stalling in metal.

8. When bit has completely penetrated work and is spinning freely, withdraw

it from the work while the motor is still running, then turn off drill.

IT’S A

HAMMER DRILL

Fig.. 10B