2

Scroll Air Compressors

GREASE DELIVERY

SLAE03 SLAE05

Bearing 1st Time 2nd Time 1st Time 2nd Time

Orbit Scroll Bearing 5 Times 3 Times 6 Times 4 Times

Pin Crank Bearing Orbit Scroll Side 5 Times 3 Times 6 Times 4 Times

Pin Crank Bearing Housing Side 5 Times 3 Times 6 Times 4 Times

NOTE: Each pump of the grease gun equals 0.65 grams of grease.

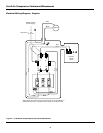

Figure 2

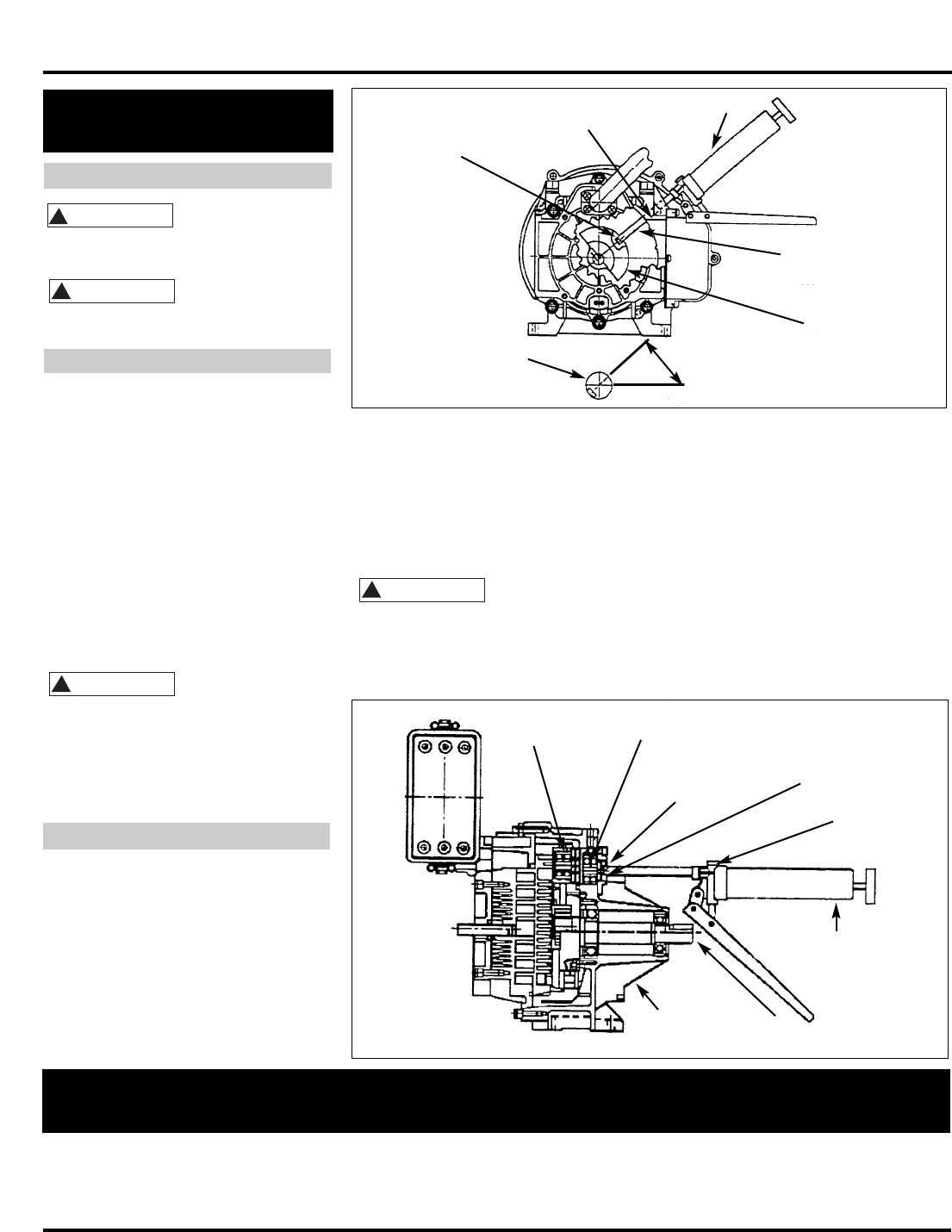

Figure 3

45°

Grease

Fitting

Grease Gun

Extension

Adaptor

Counter

Weight

Key

Way

Extension

Adaptor

Orbit Scroll

Bearings

Grease Fitting

Housing

Side Bearings

Grease

Gun

Plastic

Dust Cap

3 Grease Caps

Air End Pulley & Cooling

Fan (Not Shown)

Fan Duct Shroud

(Not Shown)

Per OSHA

regulations, ALL

power must be locked out before per-

forming any maintenance.

This service should

be performed by an

authorized Powerex Service Center to

avoid failure.

1. Remove the plastic dust cap. Use

only one of two locations found on

the air end (See Figure 2).

2. Rotate the compressor pulley until

the grease fitting is visible through

the dust cap hole (See Figure 2).

This will allow regreasing of the

main bearings.

3. Use a grease gun extension adaptor

to engage the grease fitting and

supply the proper volume of grease

as indicated on the grease delivery

chart (See Grease Delivery chart

below & Figure 2).

Use only Powerex

genuine grease.

Pump grease gun before feeding (this

eliminates air from the grease passage

of the extension adapter. (Complete

Grease Kit Part Number IP616200AJ and

Grease Tube Part Number IP600000AV).

4. Replace plastic dust cap.

The bearings on the scroll compressor

are regreaseable to allow extended

compressor life. Service should be per-

formed every 10,000 hours of opera-

tion.

1. Remove the V-Belts and the fan

cover.

2. Remove the air end pulley and cool-

ing fan with a gear puller (See

Figure 3).

!

CAUTION

!

CAUTION

!

WARNING

Grease Compressor

Bearings

10,000 HOURS - MAINTENANCE

3. Remove the fan duct shroud.

4. Remove the three grease caps. Do

not attempt to loosen or tight-

en the bolt.

5. Grease all three pin crank bearings

(See Figures 3, 4 & 5 and Grease

Delivery Chart below).

The grease fitting,

located in the cen-

ter of the pin crank bearing, feeds only

the orbit scroll side bearing. Use a

needle adapter to supply grease to the

housing side bearing. PUMP GREASE

!

CAUTION

GUN BEFORE FEEDING TO ELIMINATE

AIR FROM GREASE PASSAGE OF THE

NEEDLE ADAPTER. Hold grease gun for

5 - 10 seconds after feeding to prevent

grease blowback from the grease fit-

ting.

6. Replace grease caps, fan shroud,

pulley, etc.

(See Scroll Service and

Maintenance Video for Audio and

Visual Instructions.)

GREASING PIN CRANK BEARINGS

MAIN BEARINGS