5

Scroll Air Compressors

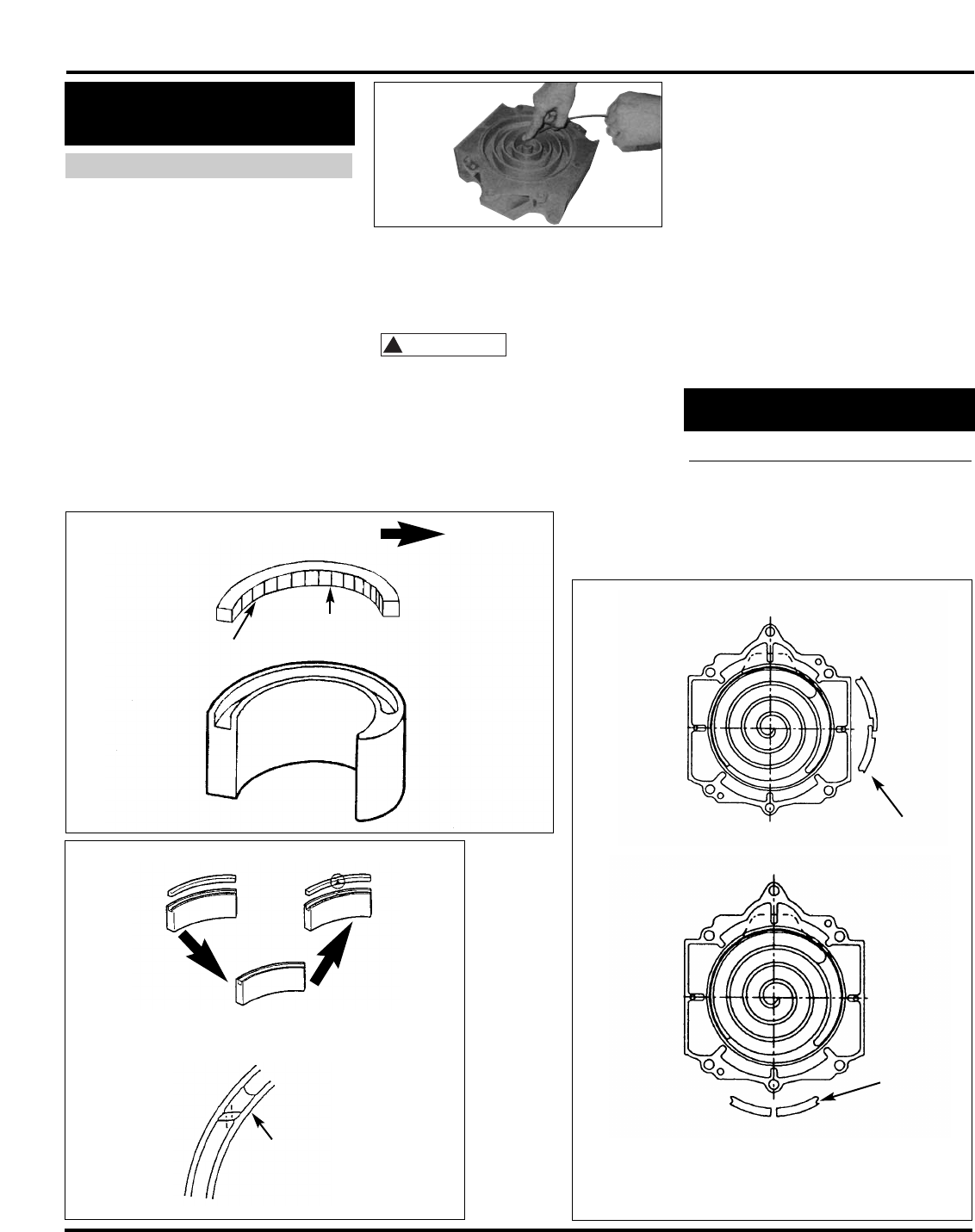

Figure 9

Lip Direction

Lip Surface

(Inside)

Enter

Side

Lip Side

(Grooved Bottom)

Machined

To Avoid Movement

During Installation

Figure 10

Dust

Seal

3 o’clock

Position

6 o’clock

Position

Back-up

Tube

Figure 8

Figure 11

NOTE: Tips seals for Fixed Scroll and

Orbit Scroll have opposing seal cut

angels (See NOTE and explanatory dia-

gram below).

Insert tip seal so that the lip of tip seal

is on the bottom of seal groove and

inner side of involute and the direction

of lip faces the center of involute (curv-

ing spiral). See Figure 9. This is to be

done for both FS and OS sets.

Use caution not to tear or distort lip.

1. Insert new HP tip seal from the cen-

ter section for OS or Orbit Scroll so

that there will be no clearance at the

tip (start) section (See Figure 8

and 9).

2. Insert so that new LP tip seal will

contact closely with HP tip seal

inside Scroll Groove (See Figure 7

on page 4).

Insert approxi-

mately half of the

LP tip seal and remove the tip seal to

confirm that a notch in the tip seal has

been achieved. This will prevent move-

ment during installation (See Figure

11).

3. Repeat the same procedure for FS

or Fixed Scroll tip seal set, remove

!

CAUTION

INSERTING TIP SEALS

Tip Seal Set

Replacement

(Continued)

both the dust seal and backup tube

located on outermost side FS set.

4. Insert new backup tube in the FS

Scroll in the 6 o’ clock position (See

Figure 10).

5. Insert new dust seal on the backup

tube. Face seamed section of the

dust seal in the 3 o’clock position

(See Figure 10).

8. After replacing tip seal set, reassem-

ble Fixed Scroll set to the Orbit

Scroll. Tighten 6 nuts temporarily

and confirm if crankshaft rotates

smoothly by hand and tighten them

firmly. Tightening torques are:

NOTE: Assemble so that dust seal and

tip seal will not drop between Orbit

Scroll set and Fixed Scroll set.

Bolt

Torque First Second

SLAE03/SLAE03HP 15 in lb. 175 in lb.

SLAE05/SLAE05HP 15 in lb. 175 in lb.