covers. The operators’ manual included with the POWERMATIC 15HH has a full set of

illustrated instructions for making these adjustments.

To enhance operator safety, we added a row of closely spaced anti kickback fingers. These steel

fingers are gravity operated and require no adjustment. They automatically engage the wood as it

enters the cutterhead and help prevent it from being kicked out.

While the POWERMATIC 15HH is capable of 3/16”-deep cuts on most stock widths, a limiter

plate at the center of the cutterhead limits full-width cuts to 1/8” or less. Controlling full-width

cut depth avoids applying excessive strain to the machine but also prevents damaging the wood.

Deep cuts are far more likely to produce chipping and tearout

because of the extraordinary stress applied to the wood fibers.

Dust Collection

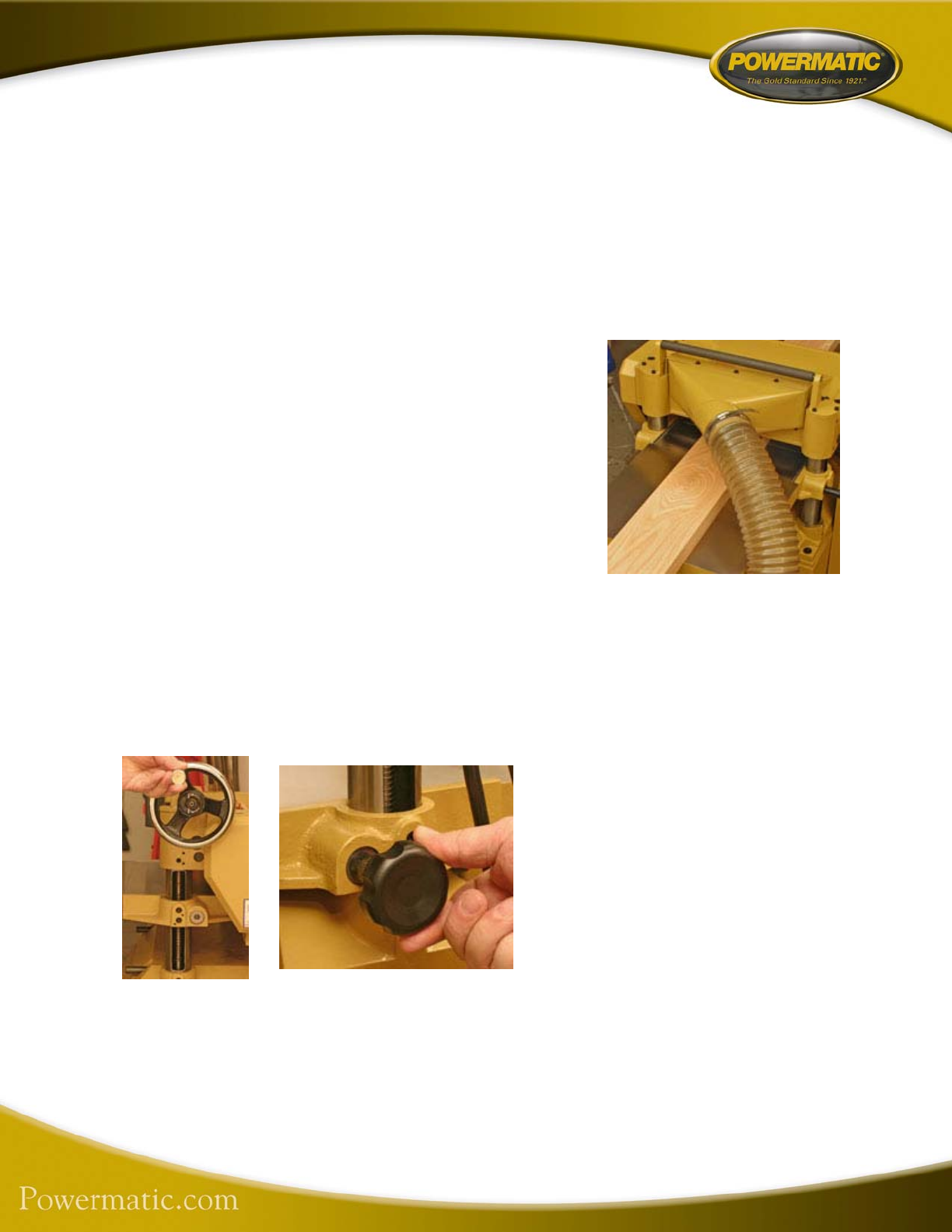

The POWERMATIC 15HH generates large quantities of dust

and chips that must be evacuated to maintain performance at

the cutterhead. The efficiency of the POWERMATIC 15HH

doesn’t reduce that quantity though its cutting action does tend

to produce smaller particles than a long knife machine. We

recommend a 500-600CFM (cubic feet per minute minimum)

dust collector to handle the flow of chips properly.

An all-metal dust hood comes with the POWERMATIC 15HH

that creates a short, direct path for the debris directly from the

cutterhead. The hood terminates with a 4”-diameter port that is angled to the side so the dust

collector hose does not interfere with the stock as it exits.

The dust chute angles the 4”-diameter

port to the side so the hose does not hang

in the way of the wood as it exits from

under the cutterhead.

Table and Adjustment

The main and extension cast iron table

surfaces are precision ground for

precise planning. The main table

surface is 20”-long by 15”-wide and is

fully captured on four round, 2”-

diameter, precision ground steel posts.

Each corner of the table is locked onto a

lead screw within its post that controls

the up and down movement. The lead

screws are driven by a single chain

through a gear drive. A large 6”-

diameter cast iron handwheel with

spinner handle drives the height

adjustment mechanism. Each full

Table height is adjusted with a large (left) cast iron handwheel with a

spinner knob. A pair of locking knobs (right) one at each end of the

table locks it in position firmly. These locking knobs can be moved to

the opposite side of the 15HH if space is an issue.