14

6. Inspect the cutting edge of the knives for

nicks or wire edge. Hone the knives slightly

using a stone or if the knives are to be

sharpened, maintain a cutting angle of 35

degrees.

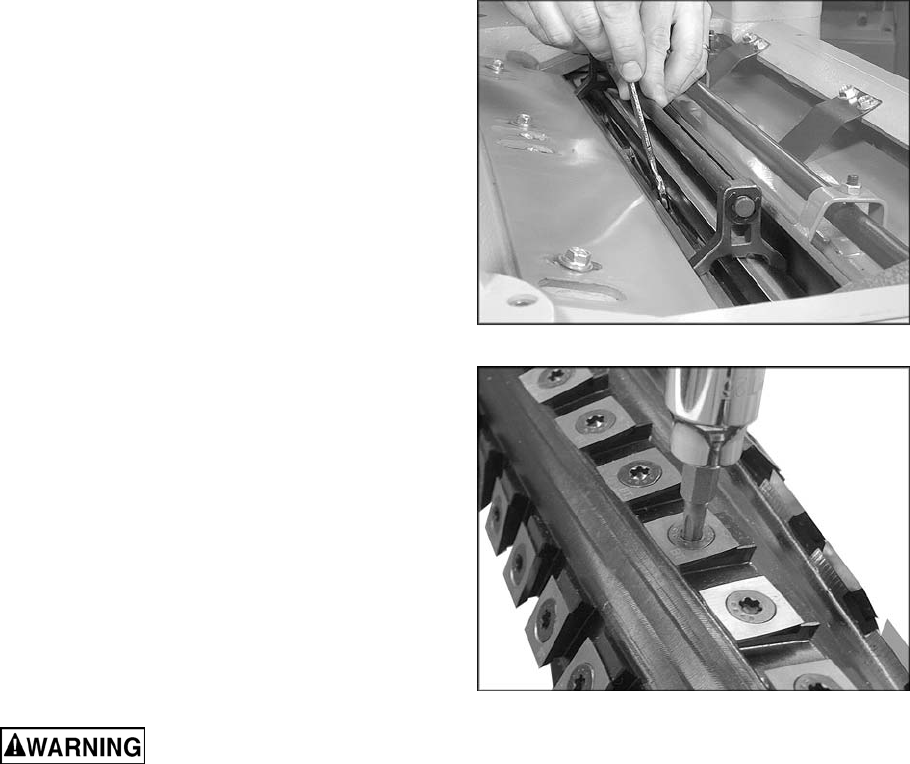

7. Insert springs, knife and gib into slot of

cutterhead. Back out screws just enough to

hold the knife in the cutterhead.

8. Place knife setting gauge (Figure 19) over

knife.

9. While holding down the knife gauge, loosen

all six screws by turning them into the gib

until the cutting edge of the knife comes in

contact with the protrusion of the gauge.

Snug up the gib by slightly backing out the

six screws against the slot.

NOTE: At this time, only tighten the knife

into the slot just enough to hold the knife in

position.

10. Replace and re-set the other three knives in

the same manner.

11. After all four knives are set with the screws

just snug, back out and tighten the six

screws against the slot starting with the end

screws first and then the center screws until

the knife is securely held in the cutterhead.

Tighten the remaining three knives in the

same manner.

After replacing and checking

knives, check again carefully. Make certain

the direction of knives is correct and all 24

gib screws are tightened securely.

Replacing or Rotating Knife Inserts

(Model 209HH only)

The knife inserts on the model 209HH are four-

sided. When dull, simply remove each insert,

rotate it 90° for a fresh edge, and re-install it.

Use the provided screwdriver with the T25P

socket adaptor to remove the knife insert screw.

See Figure 20. NOTE: A T25 adaptor or driver

can round out the screw head recess. Always

use a T25-Plus driver or adaptor.

It is advisable to rotate all inserts at the same

time to maintain consistent cutting. However, if

one or more knife inserts develops a nick, rotate

only those inserts that are affected.

Each knife insert has an etched reference mark

so you can keep track of the rotations.

IMPORTANT: When removing or rotating

inserts, clean saw dust from the screw, the

insert, and the cutterhead platform.

Figure 19 repeated

Figure 20 – Model 209HH only

Dust accumulation between these elements can

prevent the insert from seating properly, and

may affect the quality of the cut.

To install new knife inserts:

1. Before installing each screw, lightly coat the

screw threads with machine oil and wipe off

any excess.

2. Position knife insert and move it back and

forth to verify there are no burrs or dirt.

3. Hold insert away from the back of the seat

(pull slightly toward yourself if facing the

cutting edge) and allow the screw to pull

insert into position. Note: A slight offset

between screw hole and hole in knife insert

is normal. Do not position insert directly over

screw hole, as it could ride up on the back of

the seat and potentially cause cracking of

the tip.

4. Securely tighten each screw which holds the

knife inserts before operating the planer.

IMPORTANT: Maximum torque for

tightening the screws is 45 to 55 inch

pounds (3.75 to 4.6 foot pounds).