Helical Cutterhead

There are many cutterhead designs

that carry the helical label, including

simple straight blades broken into

segments and dispersed around the

cutterhead cylinder. However,

despite the name, they retain many

of the liabilities of the long blade

designs. While designing the PJ-

882HH 8" Parallelogram Jointer we

wanted to incorporate the

performance of a true segmented,

shear-cutting helical head.

The PJ-882HH 8" Parallelogram

Jointer helical cutterhead is so

effective because its carbide inserts are arranged in spiral-shaped rows. The inserts have a 4”

radius ground into them and are mounted so they approach the wood at a 14-degree angle. That

creates a true shear cut that eliminates much of the impact and the resulting fiber disturbance

other cutterhead designs deliver to the wood.

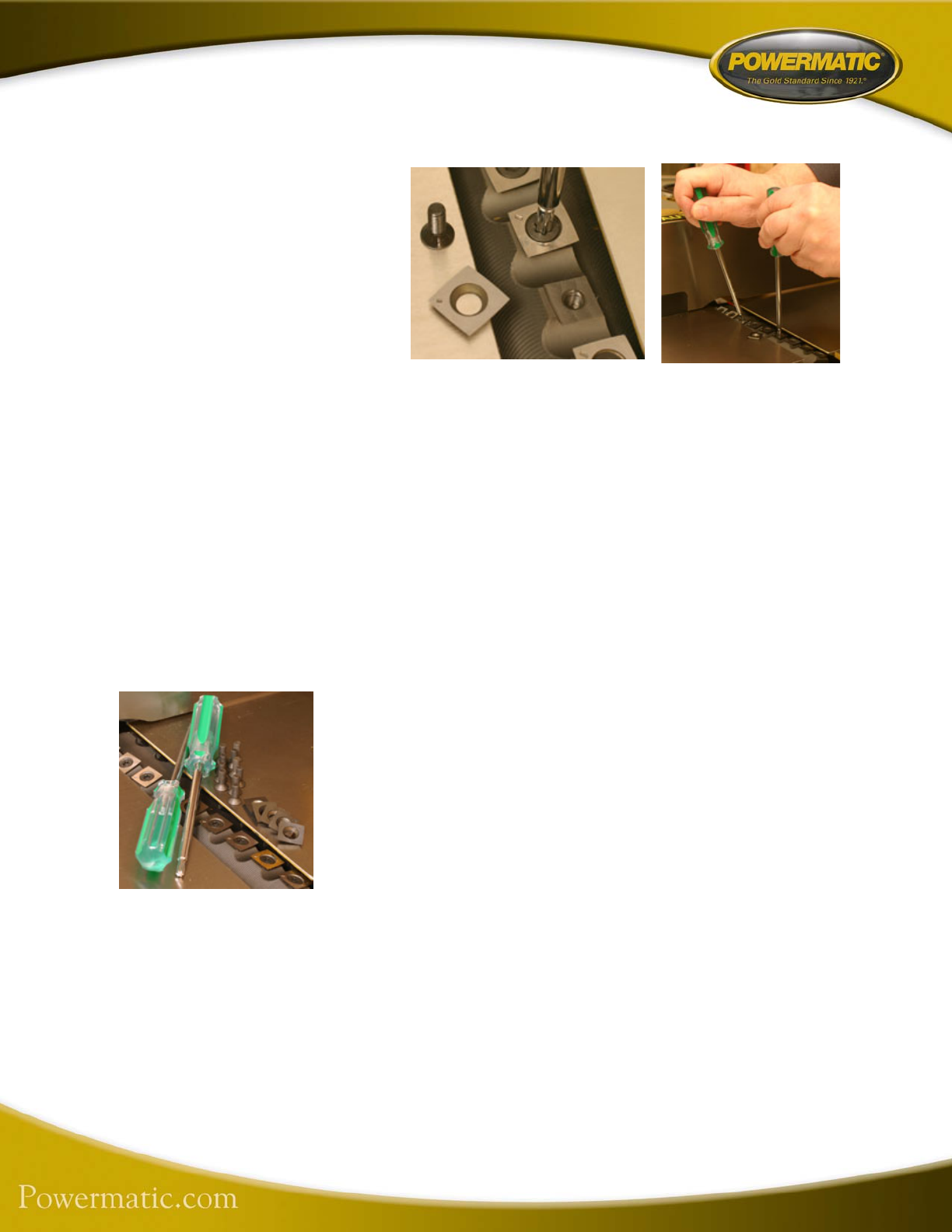

The helical cutterhead (left) uses individual solid carbide cutters, each with

four cutting edges that can be “indexed” four times should the first edge

become dull. We include five extra carbide cutters, screws and two drivers

with the PJ-882HH. One driver is placed in a screw to hold the head steady

while the other driver loosens the screw at the cutter to be replaced or

indexed.

The helical cutterhead cuts so efficiently that it dramatically reduces the noise made when

cutting wood. In fact, it is so quiet, new PJ-882HH 8" Parallelogram Jointer users often think it is

not cutting wood at all, until they see the results. The shearing effect of the helical cutterhead

produces a remarkably smooth surface on even heavily figured wood.

The helical cutterhead inserts are precisely machined from solid

high-grade carbide, each with four identical cutting edges. If an

edge eventually goes dull, you simply index it to the next cutting

edge! Each insert has a marking at one edge that makes indexing

all or any number of them the same way very easy, though

needing to do that is unlikely.

Because the inserts themselves and the seats into which they fit

are so precisely machined, there is no adjustment or “fitting”

necessary. Indexing or replacing an insert takes just seconds.

Simply loosen its retaining screw, turn the insert to its new

position and tighten the screw.

The durability of the carbide combined with the low impact, shear cutting action mean the inserts

have an extremely long life, far exceeding that of straight blades. The potential life span of these

carbide inserts means that many PJ-882HH 8" Parallelogram Jointer users may go years before

having to index them. Should a hidden piece of metal be encountered and actually damage a few

of the carbide inserts only the ones actually contacting the metal need to be indexed or replaced.

The solid carbide cutters in the

helical head last far longer than

straight knives, but just in case, we

provide extra cutters, screws and

drivers to install them