Millermatic Python

®

Owner's Manual - Page 6

Section D Maintenance

Periodic Maintenance

Your Millermatic Compatible™ Python

®

is designed to provide years of

reliable service. Maintenance of the gun will normally consist of a general

cleaning of the wire guide system, including barrels, drive rolls, and conduits

at regular intervals.

Remove spatter build-up from inside of nozzles with a hardwood stick.

The only parts that are subject to normal wear are the conduit, contact tips,

nozzles, barrel liners, wire guides, drive and idler rolls. A supply of these

parts should be maintained on hand.

The number of units in operation and the importance of minimal down time

will determine to what extent spare parts should be stocked on hand. See

the recommended spare parts list for the most commonly replaced parts.

If repairs do become necessary, qualied shop maintenance personnel can

easily replace any part.

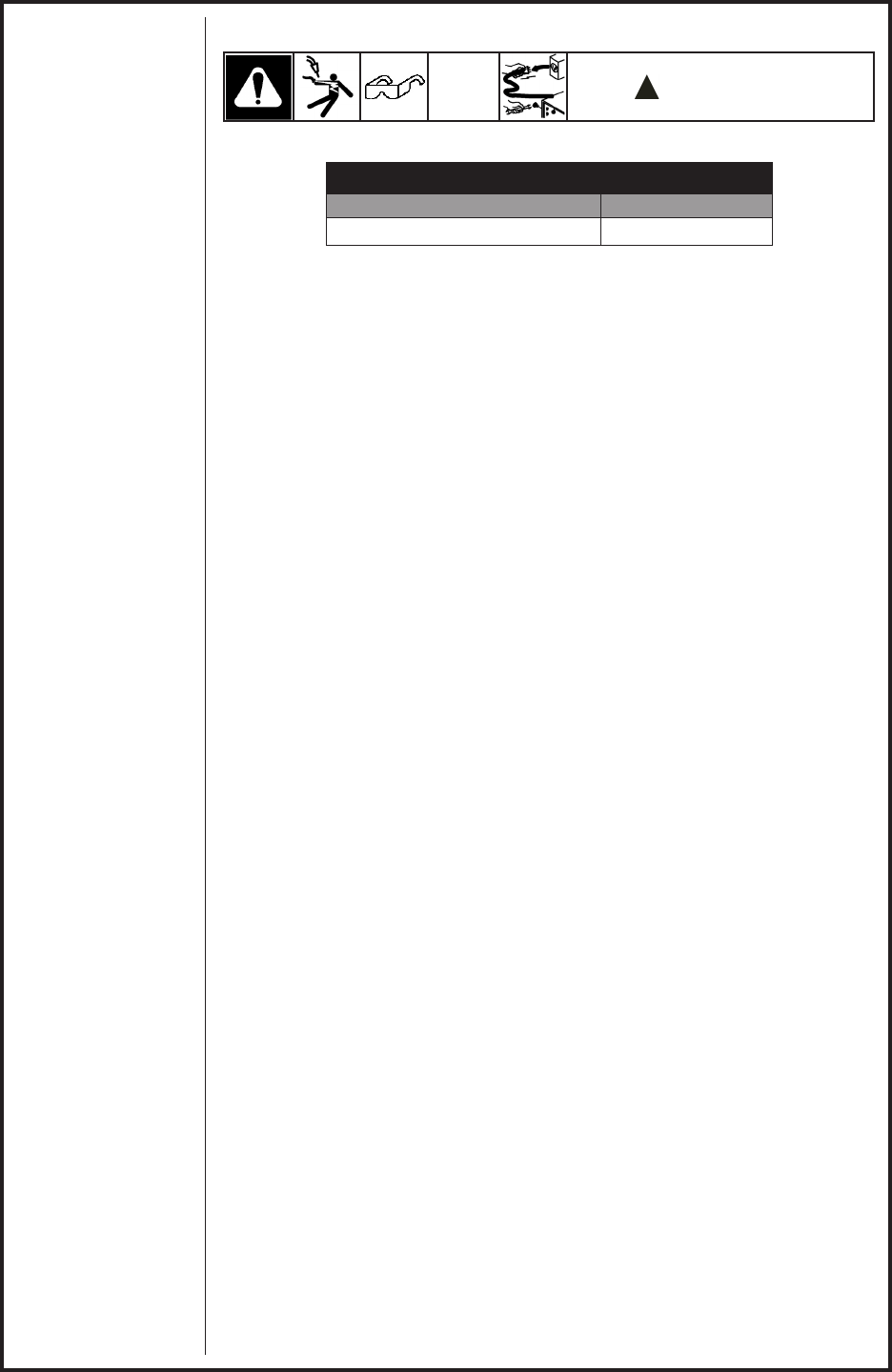

Reference the table below for suggested Maintenance Tools used with the

Millermatic Compatible™ Python

®

welding gun.

Testing The Gun

Reference the "X" clocked Amphenol diagram

on the Millermatic Compatible™ Python

®

electrical diagram

for information about pin-outs and locations.

Motor Check

Remove the connector from the cabinet.

Using the Amphenol connector, check the resistance across pins “C” and

“B” (motor leads). The resistance across the motor should be between 5

- 10 ohms as the potentiometer is turned.

If an open circuit or short exist, check the motor leads and motor

independently.

Testing the Gun Potentiometer

Using the amphenol connector, check the resistance across pin “F”

(wiper) and pin “E”. The resistance should vary from 0 - 5K ohms as the

potentiometer is turned.

Check the resistance across pin “F” (wiper) and pin “H”. The resistance

should vary from 5K - 0 ohms as the potentiometer is turned.

Testing the Micro Switch

Using the amphenol connector, check for continuity across pins “D” and “G”

when the trigger is pressed.

Maintenance Tools

Tool Part No.

Drive Roll Removal Tool 931-0100

Disconnect Power

Before Maintaining.