19

1

5

2

0

2

5

3

0

3

5

4

0

4

5

5

0

1

0

ASSEMBLY

CUTTING A SLOT IN THE ZERO CLEARANCE

THROAT PLATE

In order to use your compound miter saw, you must cut

a slot through the zero clearance throat plate to allow for

blade clearance. To cut the slot, set your saw at 0

°

miter,

turn saw on and allow the blade to reach full speed, then

carefully make a straight cut as far as it will go through the

throat plate. Turn your saw off and allow the blade to come

to a complete stop before raising the saw arm.

Next, adjust the bevel angle to 45

°

, turn your saw on and al-

low the blade to reach full speed, then carefully make another

cut through the zero clearance throat plate. The slot in the

throat plate will then be wide enough to allow the blade to

pass through it at any angle from 0

°

to 45

°

.

NOTE: Many of the illustrations in this manual show only

portions of the compound miter saw. This is intentional

so that we can clearly show points being made in the

illustrations. Never operate the saw without all guards se-

curely in place and in good operating condition.

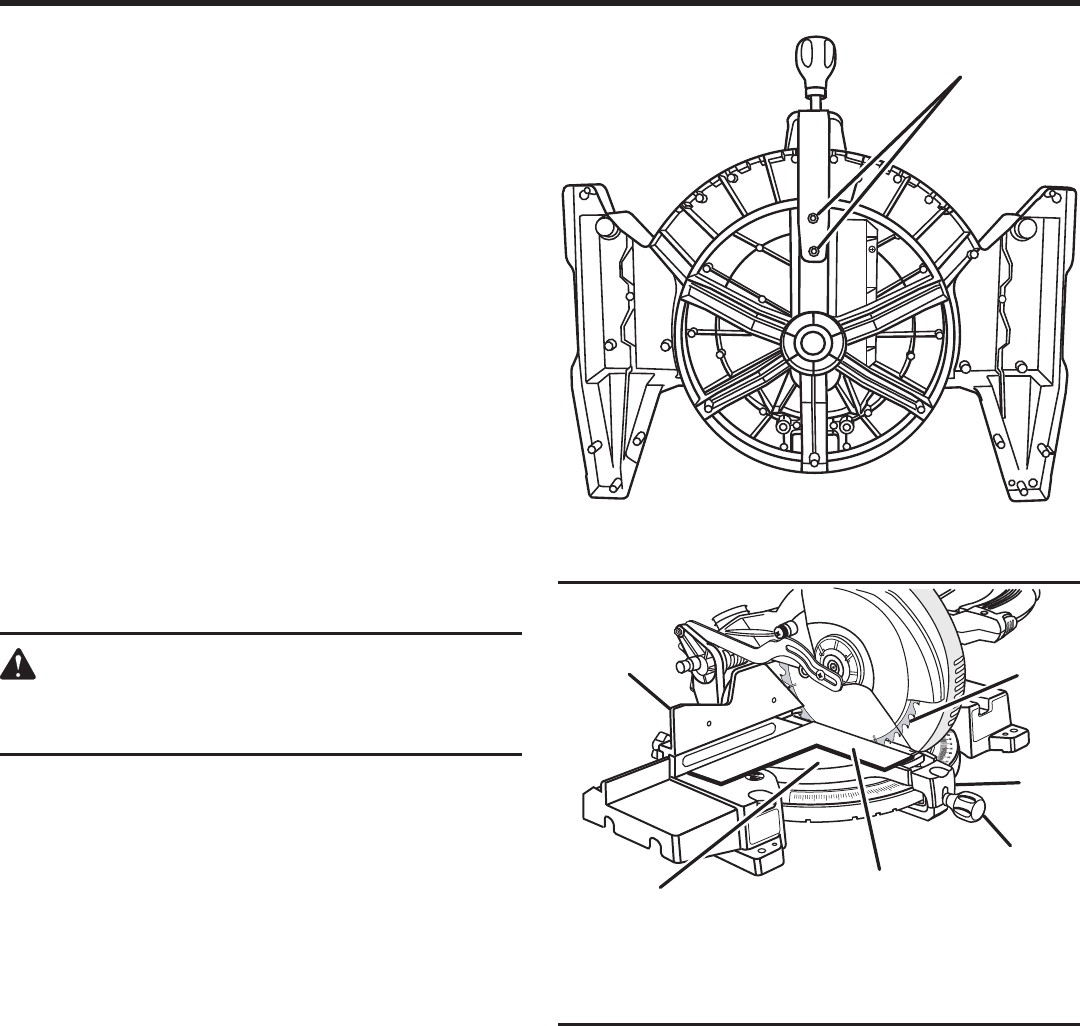

SQUARING THE SAW BLADE TO THE FENCE

See Figures 16 - 21

Unplug the saw.

WARNING:

Failure to unplug your saw could result in accidental

starting causing possible serious personal injury.

Pull the saw arm all the way down and engage the lock

pin to hold the saw arm in transport position.

Loosen the miter lock handle approximately one-half

turn.

Depress the miter lock plate and rotate the miter table

until the pointer on the control arm is positioned at 0

°

.

Release the miter lock plate and securely tighten the miter

lock handle.

Lay a framing square flat on the miter table. Place one

leg of the square against the fence. Slide the other leg

of the square against the flat part of saw blade.

NOTE: Make sure that the square contacts the flat part

of the saw blade, not the blade teeth.

The edge of the square and the saw blade should be

parallel as shown in figure 17.

If the front or back edge of the saw blade angles away

from the square as shown in figures 19 and 20, adjust-

ments are needed.

Fig. 17

VIEW OF BLADE SQUARE WITH FENCE

Fig. 16

SLIDING

MITER

FENCE

BLADE

MITER

LOCK

PLATE

MITER

LOCK

HANDLE

FRAMING

SQUARE

MITER

TABLE

CAP HEAD

SCREWS