Ridge Tool Company

6

Threading with 11-R Die Head

1. For 1

1

/

2

″ - 2″ 11-R Die Heads, push die heads, spline

end first, squarely into the Power Drive until the spring

engages securely (Figure 3). For

1

/

8

″ - 1

1

/

4

″ 11-R Die

Heads, push die heads into adapter spline end first,

until spring engages in notches.

NOTE! Installation can be made from only one side of

the Power Drive.

Figure 3 – Installing No. 11-R Die Heads

2. If possible, secure the pipe in a portable tristand vise

or a bench vise.

To prevent tipping, long lengths of pipe

should also be supported with pipe stand.

3. Be sure the 418 Oiler is properly filled with RIDGID

Thread Cutting Oil. Position the oiler in front of the vise.

4. Position No. 691 Support Arm on pipe so end of

support arm is in line with end of the pipe (Figures 4

& 5). Make sure jaws squarely contact pipe and

tighten handle firmly to prevent slipping of the jaws.

To avoid serious injury from losing control

of the Power Drive, a support arm should be used when

threading

3

/

4

″ or larger pipe.

When threading pipe less than

3

/

4

″ in size without a sup-

port arm, hold onto the Power Drive firmly with one hand

to exert pressure against the handle forces developed dur-

ing threading.

Figure 4 – Using No. 691 Support Arm When Threading

3

/

4

″ Pipe and Larger

Figure 5 – Positioning No. 691 Support Arm In Line with

End of Pipe

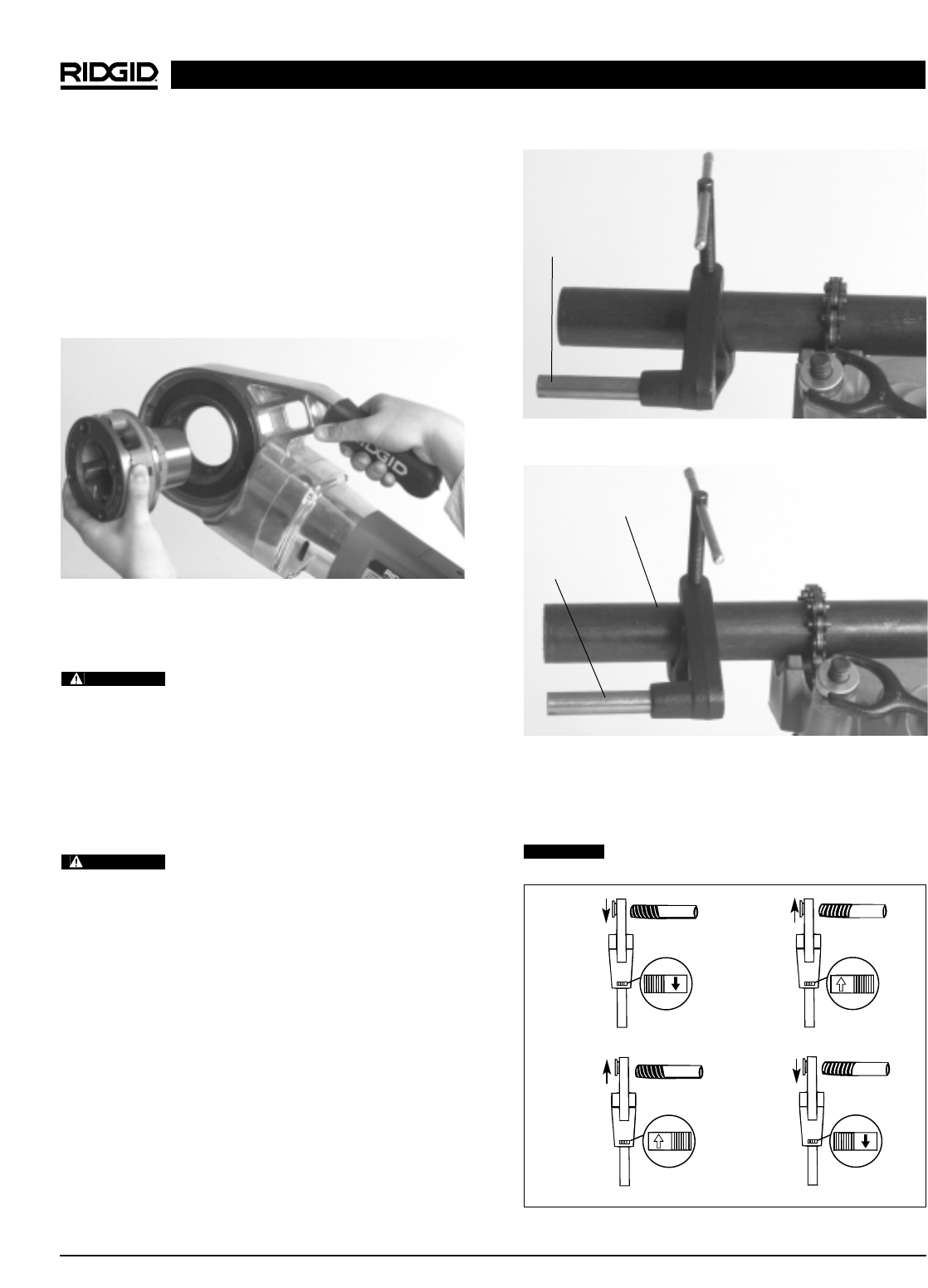

5. Position the directional switch for the desired right or

left hand thread (Figure 6).

Change position of the directional switch only

when the motor is switched OFF.

No. 690 Portable Power Drive

WARNING

Figure 6 – Direction Change Switch/Die Head Orientation

WARNING

CAUTION

Pipe

Support Arm

Support Arm

A. Right Hand Thread ON

A. Right Hand Thread OFF

B. Left Hand Thread ON

B. Left Hand Thread OFF

CLOCKWISE

CLOCKWISE

COUNTER-

CLOCKWISE

COUNTER-

CLOCKWISE