10

11

OPERATION

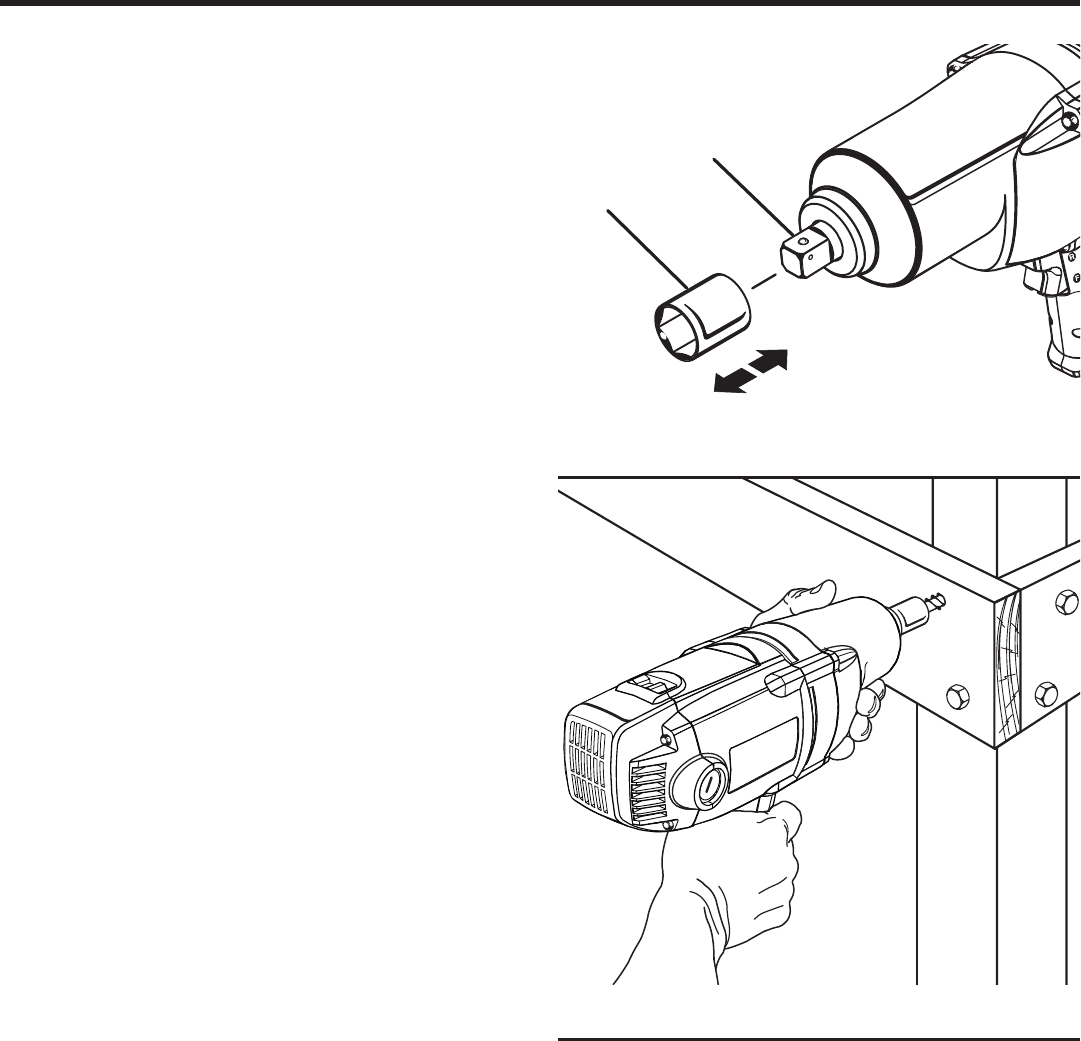

INSTALLING AND REMOVING SOCKETS

See Figure 4.

Use only sockets designed for impact wrenches. Always se-

lect the correct size impact socket for nuts and bolts. Using

the wrong size socket may damage the nut or bolt and cause

the fastening torque to be inaccurate or inconsistent.

n Unplug the wrench.

n Push the socket onto the drive shank until the detent pin

locks it into place.

n To remove the socket, pull it away from the drive

shank.

OPERATING THE IMPACT WRENCH

See Figure 5.

Proper fastening torque may be determined by the kind of

bolt, the size of the bolt or the material or the workpiece. It

is helpful to perform a test operation to determine the proper

fastening time for the nut or bolt you are using. While per-

forming the test, make note of the speed selection.

n Hold the tool pointed straight at the nut or bolt.

n Depress the switch and fasten for the proper fastening

time.

n After fastening, always check the torque with a torque

wrench.

NOTE: Do not use this tool to install lug nuts on wheels

without a torque limiting device. Doing so could result in

galled or broken lugs.

IMPACT TIME

Many variables exist that will cause the available torque of

the fastener to vary considerably. The optimum impact time

is approximately 6 seconds.

NOTE: Using a universal joint or extension bar may reduce

the fastening force of the impact wrench and require longer

fastening time.

Fig. 4

DRIVE SHANK

SOCKET

Fig. 5

TO

REMOVE

TO

INSTALL