15

OPERATION

ANGLE CUTTING (BEVEL CUTTING)

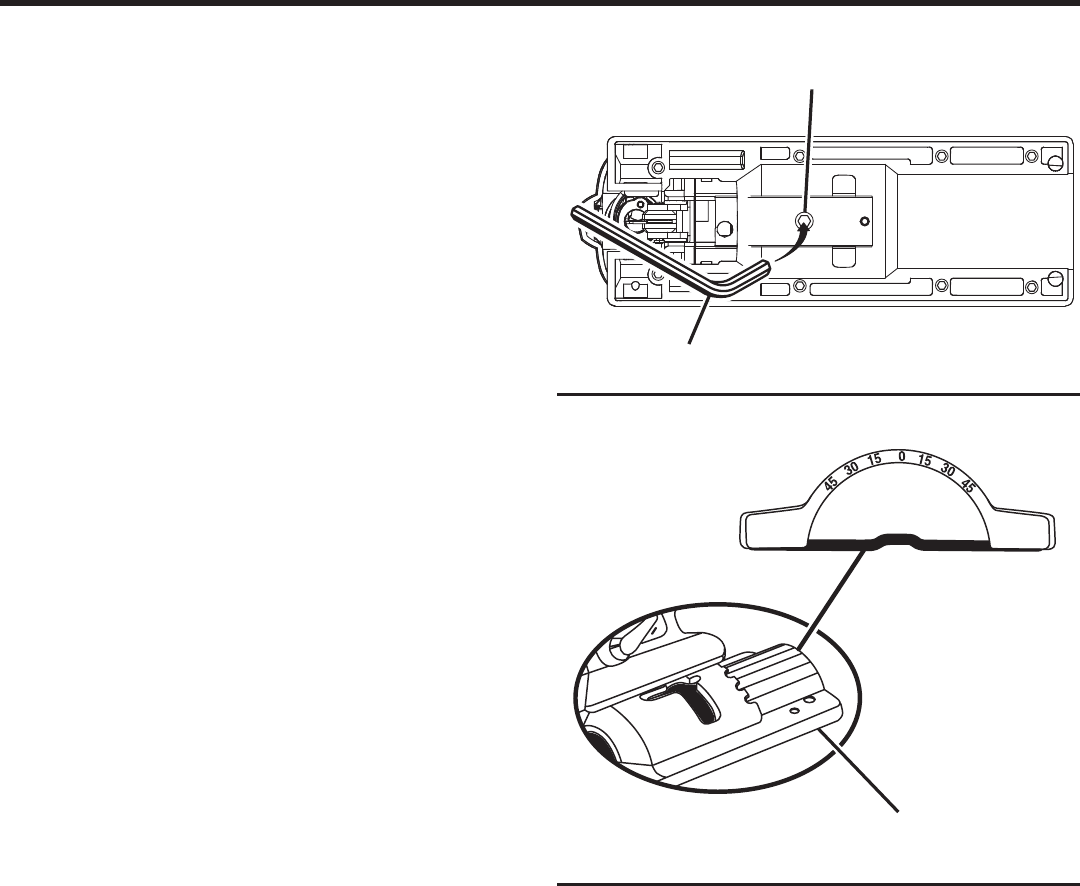

See Figures 10 - 11.

Bevel cutting angles may be adjusted from 0° to 45° right

or left. Angles for cuts from 0° to 45° in 15° increments are

marked on a scale on both the left and right side of the base.

Notches on the rear of the base provide positive stops at

each of the above mentioned 15° increments. A protractor

is recommended when accurate cuts are required.

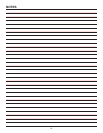

n Using the hex key provided, loosen the base pivot screw

until the base can be moved.

n Slide base forward until base pivot screws can move

freely in slots in base.

n Align the mark, on the base, of the desired angle with the

edge of the motor housing.

n Once the desired angle is reached, slide base back until

tab on motor housing aligns with the appropriate notch

on rear of base.

NOTE: When making a set-up for accurate cuts with a

protractor, or for angles other than the preset 15° incre-

ments, the positive stop notches on the rear of the base

are not used.

n Tighten the base pivot screw securely.

n Return hex key to storage compartment.

NOTE: The wide slot in the base must be used when mak-

ing bevel cuts, scroll cuts, plunge cuts, and when cutting

metal.

Fig. 10

Fig. 11

HEX KEY

BASE PIVOT

SCREW

BASE