RB-214/215 Core Drilling Machine

Ridge Tool Company6

Securing Machine

WARNING!

Drilling machine must be properly secured to the

work surface to prevent serious injury to the op-

erator.

Movement during drilling will cause chatter of bit

against work surface, fracturing diamonds. Bit

may also bind in hole causing damage to the bit.

Vacuum Anchor method should not be used to

mount machine to a wall.

Bolt Anchor Method-to-Floor

1. Measure distance from center of anchor bolt slot in

base (Figure 2) to center of drill spindle (Figure 1).

2. To locate the anchor bolt hole, use the distance ob-

tained in Step 1 and measure from the center of the

hole that is to be drilled.

3. Drill and set

1

/

2

″ anchor bolt. Place Drilling Machine

over anchor hole and hand tighten anchor bolt.

4. Adjust 4 leveling screws (Figure 1) to stabilize base

and plumb mast. Secure machine by tightening an-

chor bolt.

Bolt Anchor Method-to-Wall

Use the same bolt anchor method procedure to anchor

as above.

Also fasten a chain to the Core Drilling

Machine and secure the chain to prevent the machine

falling and causing serious injury.

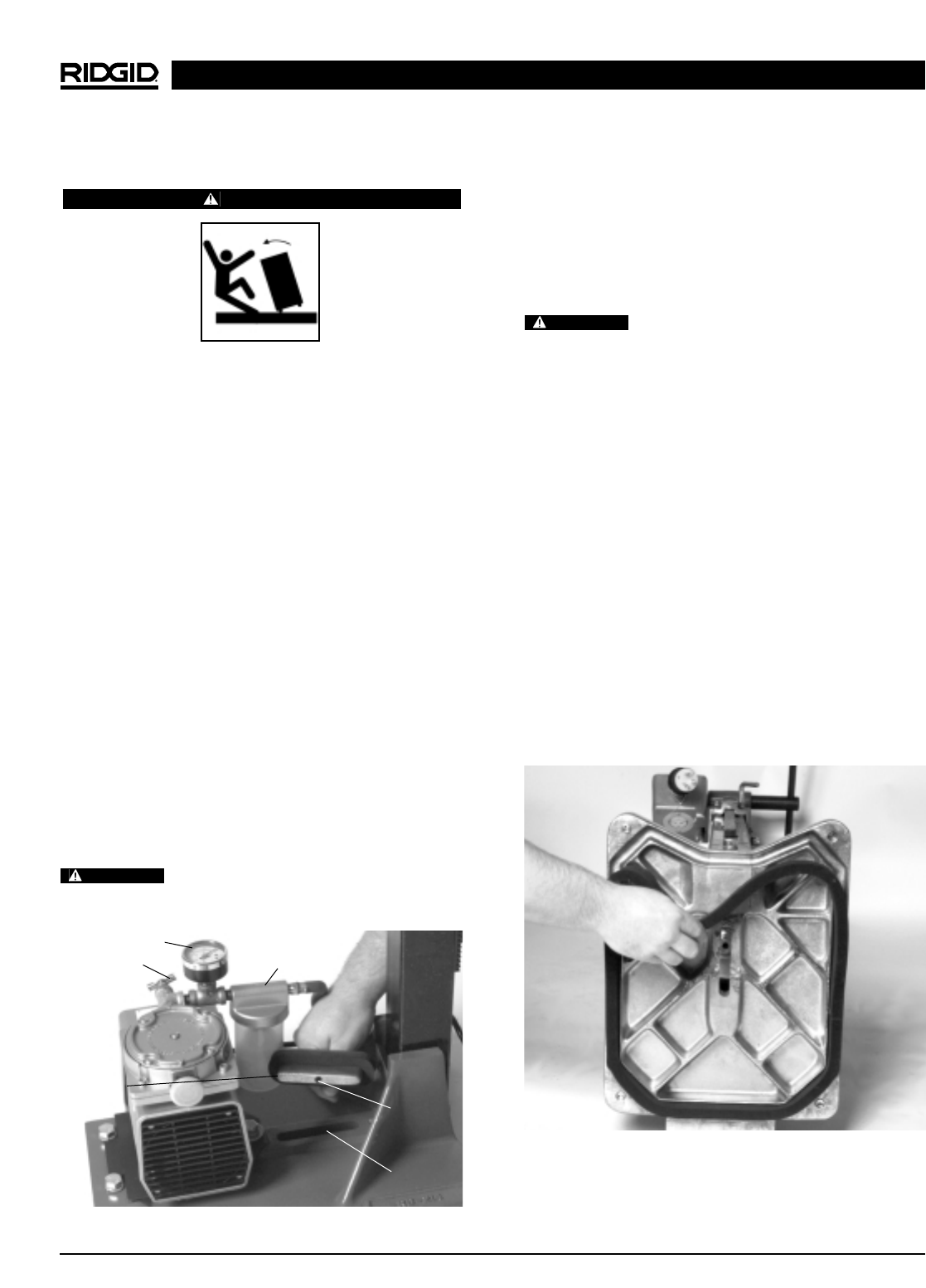

Figure 2 – Vacuum Motor and Base

Vacuum Anchor Method-to-Floor

(RB-214 Only)

The Vacuum Anchor Method is recommended for 8″

diameter holes or less. The Anchor Vacuum Method is

NOT recommended on rough or cracked floor conditions,

holes deeper than one bit length, or steel concentration

greater than standard rebar.

Do not use Vacuum Anchor Method to

mount machine to a wall.

1. Turn machine on its back and insert vacuum seal

(Figure 3) under machine base, inspecting first to en-

sure seal is in good condition and sealing groove is

clean.

2. Turn Drilling Machine up-right and loosen 4 base

leveling screws.

3. Plug power cord into a properly grounded recepta-

cle and turn vacuum pump ON/OFF switch to the

ON position.

4. Insert vacuum slot cap into anchor bolt slot (Figure

2) and check vacuum and hose connections.

Vacuum gauge (Figure 2) must read a minimum

of 20″ of mercury.

5. The drilling machine should now be vacuum anchored.

If machine does not anchor, add weight by standing on

vacuum base. It should now anchor with vacuum

gauge reading 20″ of mercury minimum. If not, check

the floor and vacuum seal (Figure 3) for leaks.

Figure 3 – Installing Vacuum Seal

6. Adjust 4 leveling screws to eliminate rocking and to

stabilize machine and plumb mast. The machine is

now ready to drill.

WARNING

WARNING

Vacuum Gauge

Opening

Vacuum

Release Valve

Vacuum

Water Trap

Vacuum

Slot Cap

Anchor

Bolt Slot