Page 29

+

-

OPERATION

TO MAKE A COMPOUND MITER CUT

It is recommended that you place the piece to be saved on

the left side of the blade and that you make a test cut on

scrap wood first.

WARNING:

Make sure the blade guard assembly is securely installed

and working properly to avoid serious personal injury.

Remove the rip fence by lifting the lock down handle.

Unlock the bevel locking lever.

Adjust the bevel angle to the desired setting.

Lock the bevel locking lever.

Set the saw blade to the correct depth.

Loosen the lock knob on the miter gauge, set the miter

gauge to the desired angle and tighten lock knob.

Turn the power switch to the on ( ) position.

Position the workpiece flat on the table with the edge flush

against the miter gauge. Let the blade build up to full speed

before feeding the workpiece into the blade.

Advance the workpiece and the miter gauge toward the

blade. Keep the workpiece flush against the miter gauge.

Push the miter gauge and workpiece toward the blade.

Stand slightly to the side of the wood as it contacts the

blade to reduce the chance of injury should kickback occur.

When the cut is made, turn the saw off ( ). Wait for the

blade to come to a complete stop before removing the

workpiece.

After the blade has stopped completely, remove the cutoff

stock.

TO MAKE NON-THROUGH CUTS

Non-through cuts can be made with the grain (ripping) or

across the grain (crosscut). The use of a non-through cut is

essential to cutting grooves, rabbets, and dadoes. This is the

only type cut that is made without the blade guard installed.

Make sure the blade guard assembly is reinstalled upon

completion of this type of cut. Read the appropriate section

which describes the type of cut in addition to this section on

non-through or dado cuts. For example, if your non-through

cut is a straight cross cut, read and understand the section

on straight cross cuts before proceeding.

WARNING:

Unplug the saw to avoid possible injury.

Remove the screw holding the throat plate in place.

Remove the throat plate.

Raise the saw blade.

Put the saw in angle mode by pushing the bevel locking

lever to the right. Turn the blade adjusting handle until the

blade indicator shows a 30° angle. Push the bevel locking

lever securely to the left to lock the angle.

Loosen the two hex nuts at the base of the riving knife.

Do not remove hex nuts. Remove the riving knife/

guard assembly. Retighten the two hex nuts on the

base.

Lower the blade and insert the throat plate, then securely

tighten the throat plate screw.

Bring the blade back to 90°.

Raise the blade to the correct height by turning the blade

adjusting handle counterclockwise.

Feed the workpiece into the blade.

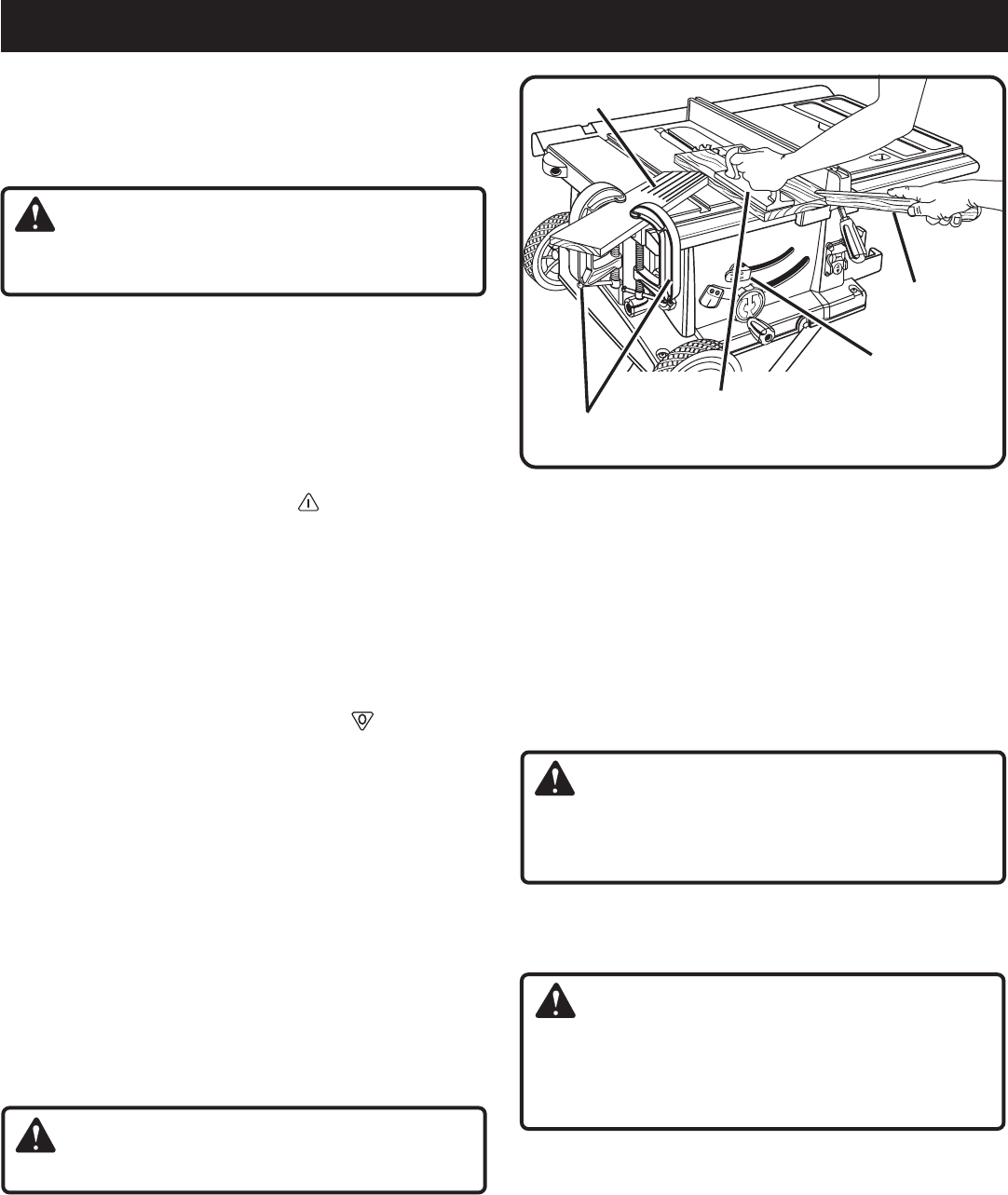

WARNING:

Carefully check all setups and rotate the blade one full

revolution to assure proper clearance before connecting

saw to power source.

Always use pushblocks, pushsticks, and featherboards

when making non-through cuts to avoid the risk of serious

injury.

See Figure 39.

WARNING:

When making a non-through cut, the cutter is covered by

the workpiece during most of the cut. Be alert to the

exposed cutter at the start and finish of every cut to avoid

the risk of serious personal injury.

PUSHBLOCK

Fig. 39

“C” CLAMP

FEATHERBOARD

PUSHSTICK

BEVEL

LOCKING LEVER