Page 12

45

0

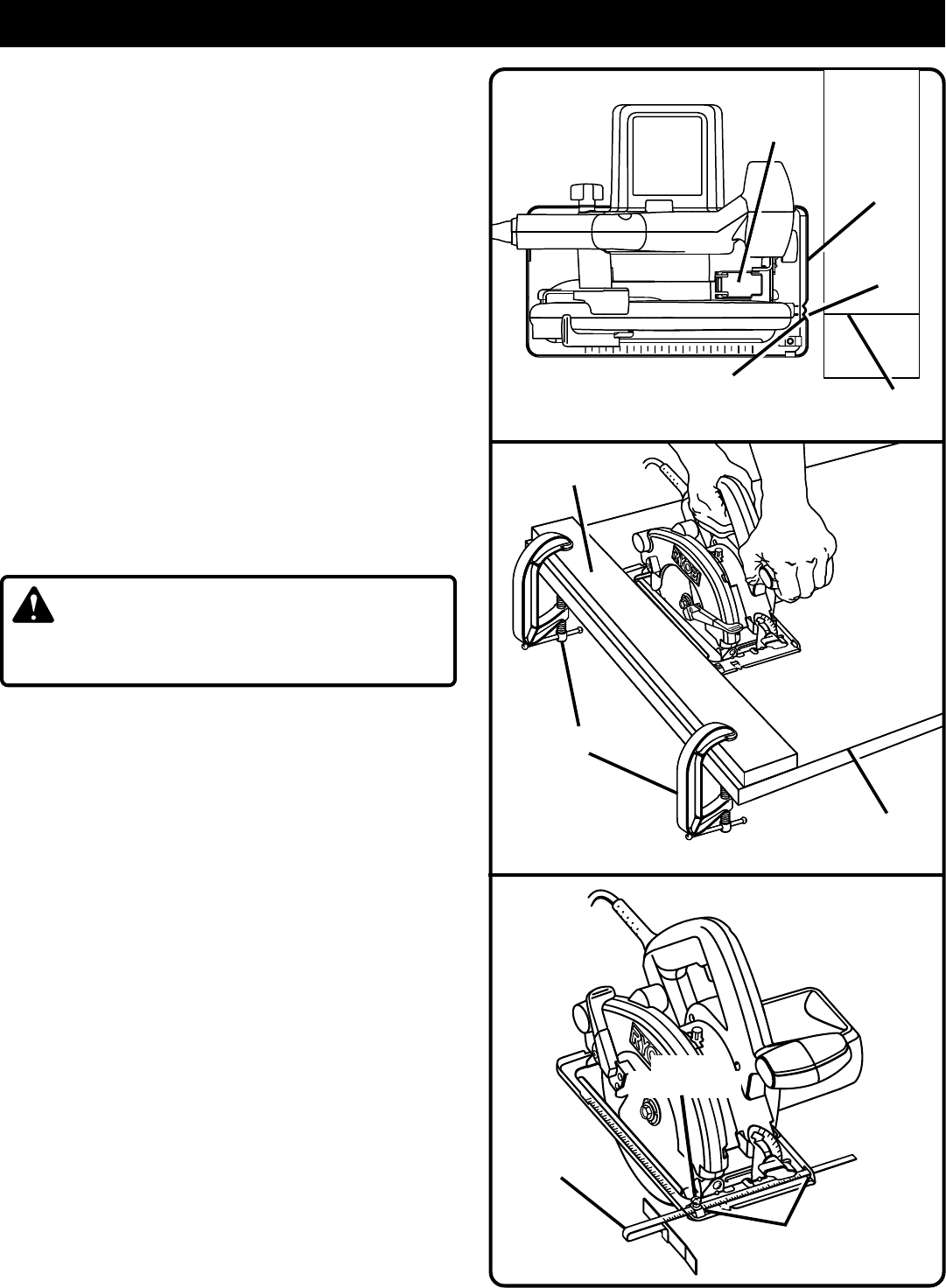

ALTERNATE METHOD FOR RIP CUTTING

4

5

4

5

0

45

0

OPERATION

TO CROSS CUT OR RIP CUT

See Figure 14.

When making a cross cut or rip cut, align your line of cut

with the outer blade guide notch on the saw base (as shown

in Figure 14) and view the blade through the viewing window.

Since blade thicknesses vary, always make a trial cut in

scrap material along a guideline to determine how much, if

any, the guideline must be offset to produce an accurate cut.

NOTE: The distance from the line of cut to the guideline is

the amount you should offset the guideline.

OPTIONAL RIP GUIDE (EDGE GUIDE)

See Figure 15.

Use a guide when making long or wide rip cuts with your

saw. An optional rip guide with a 5 in. scale is available, or

you can make an efficient rip guide by clamping a straight

edge to your workpiece. Secure the workpiece. Using C-

clamps, firmly clamp a straight edge to the workpiece and

guide the saw along the straight edge to achieve a straight

rip cut. Do not bind the blade in the cut. If using the optional

rip guide, see the following instructions and Figure 16.

TO ASSEMBLE RIP GUIDE

■ Unplug your saw.

WARNING:

Failure to unplug your saw could result in accidental start-

ing causing possible serious personal injury.

■ Place rip guide through holes in saw base as shown in

Figure 16.

■ Adjust rip guide to the width needed for the cut.

■ Tighten edge guide screw securely.

When using a rip guide, position the face of the rip guide

firmly against the edge of workpiece. This makes for a true

cut without pinching the blade. The guiding edge of the

workpiece must be straight for your cut to be straight. Use

caution to prevent blade from binding in the cut.

Fig. 14

Fig. 16

TOP VIEW OF SAW

GUIDELINE

ALIGN OUTER BLADE GUIDE NOTCH ON

SAW BASE WITH LINE OF CUT AS SHOWN

WHEN MAKING CROSS CUTS OR RIP CUTS

EDGE GUIDE

(RIP GUIDE)

PLACE RIP

GUIDE THROUGH

HOLES

STRAIGHT EDGE

C-CLAMPS

BLADE

GUIDE

NOTCH

FRONT

OF SAW

WORKPIECE

EDGE

GUIDE SCREW

VIEWING

WINDOW

Fig. 15