20 21

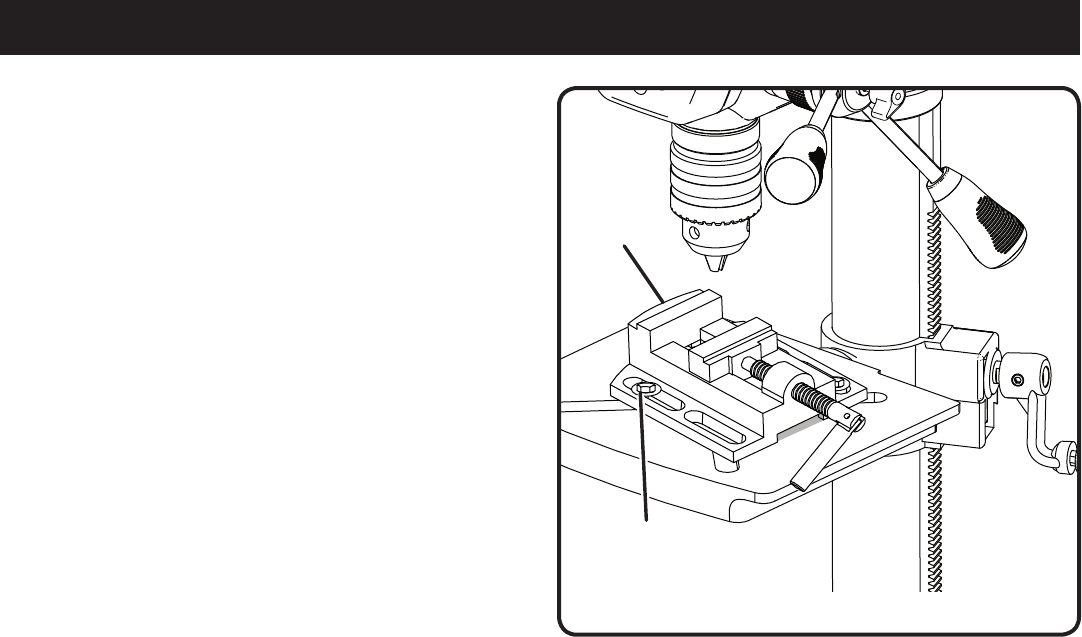

OPERATION

DRILLING

See Figure 20.

n Using the vise provided or similar clamping device, secure

the workpiece to the worktable. To protect the top surface

of the workpiece, use a piece of scrap wood between the

vise and the workpiece.

n Select the proper drill bit based on the hole size desired.

For large holes, drill a pilot hole first, using a smaller

diameter bit.

n Select and set the recommended spindle speed. Refer

to Changing Speeds in the Adjustments section of this

manual.

n Set table assembly to desired height. Refer to Adjust-

ing Table Height in the Adjustments section of this

manual.

n If desired, set feed shaft at desired spindle depth. Refer

to Adjusting Depth Gauge in the Adjustments section

of this manual.

n Make sure the work table is free of all loose objects and

the bit is not in contact with the workpiece.

n Plug electrical cord into power supply and turn switch

ON. Make sure spindle rotates freely.

n Slowly lower drill bit into workpiece. Do not force the bit;

let the drill press do the work.

n Once the hole is completed, allow the spindle to return to

its normal position. This will automatically raise the chuck

and bit.

DRILLING TIPS

n If a large hole is needed, it’s a good idea to drill a smaller

pilot hole before drilling the final one. Your hole will be

more accurately positioned, rounder, and the bits will last

longer.

n If the hole is deeper than it is wide, back off occasionally

to clear the chips.

n When drilling metal, lubricate the bit with oil to improve

drilling action and increase bit life.

n As you increase the drill size, you may need to reduce

the spindle speed.

n If drilling a through hole, make sure that the bit will not

drill into the table after moving through the workpiece.

VISE

Fig. 20

HEX

BOLT