11

20

24

5

20

24

5

20

24

5

SCREWDRIVER BIT

SCREWDRIVER BIT

LO

SPEED

HI

SPEED

TWO-SPEED

GEAR TRAIN (HI-LO)

OPERATION

TWO-SPEED GEAR TRAIN

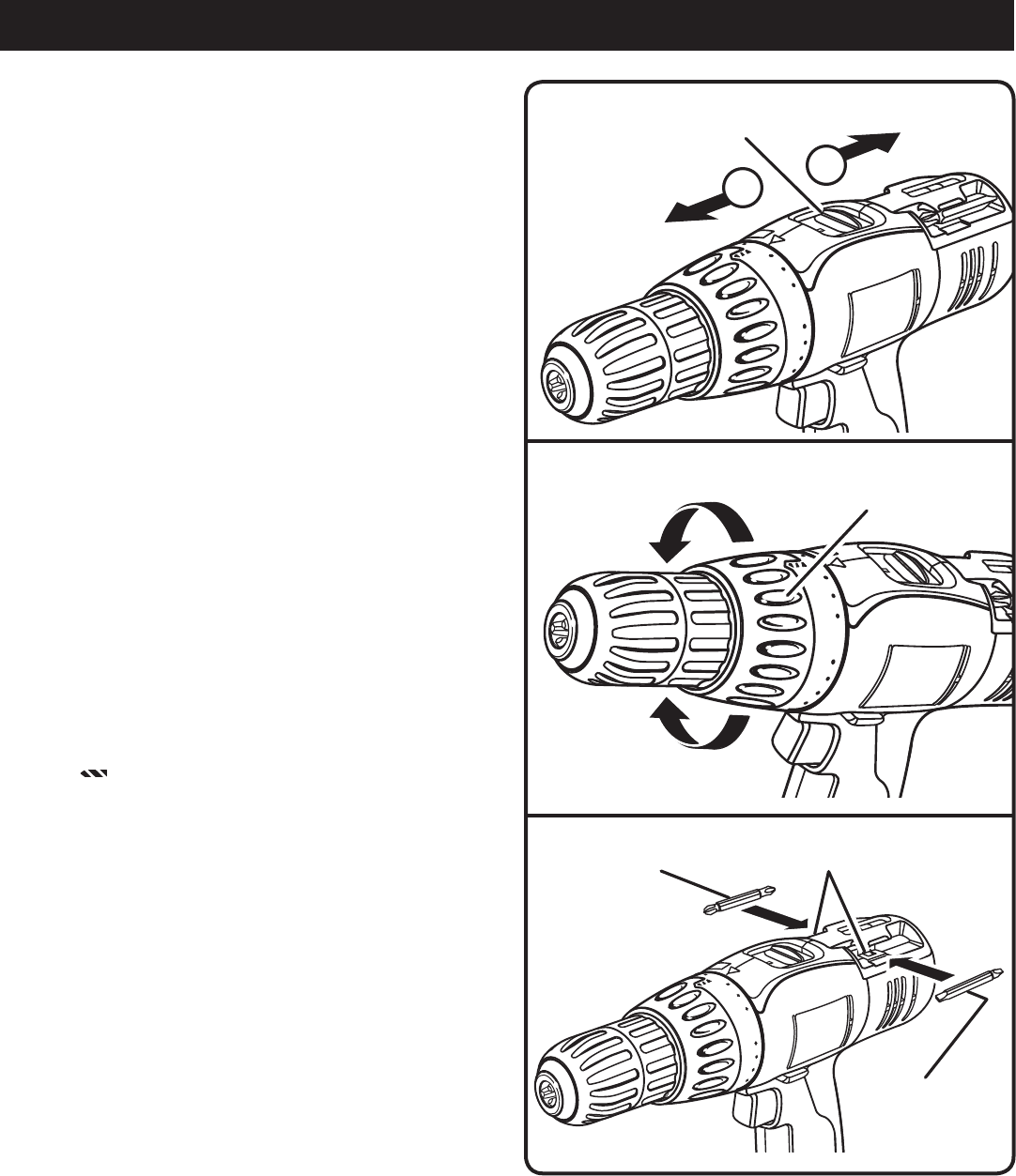

See Figure 5.

The drill has a two-speed gear train designed for drilling or

driving at LO (1) or HI (2) speeds. A slide switch is located on

top of the drill to select either LO (1) or HI (2) speed. When

using drill in the LO (1) speed range, speed will decrease

and unit will have more power and torque. When using drill

in the HI (2) speed range, speed will increase and unit will

have less power and torque. Use LO (1) speed for high power

and torque applications and HI (2) speed for fast drilling or

driving applications.

ADJUSTABLE TORQUE CLUTCH

This product is equipped with an adjustable torque

clutch for driving different types of screws into different ma-

terials. The proper setting depends on the type of material

and the size of screw you are using.

ADJUSTING TORQUE

See Figure 6.

There are twenty-four torque indicator settings located on

the front of the drill.

Rotate adjustment ring to the desired setting.

• 1-4 Fordrivingsmallscrews

• 5-8 Fordrivingscrewsintosoftmaterial

• 9-12 Fordrivingscrewsintosoftandhard

materials

• 13-16 Fordrivingscrewsinhardwood

• 17-20 Fordrivinglargescrews

• 21- Forheavydrilling

BIT STORAGE

See Figure 7.

When not in use, bits provided with the drill can be placed in

the storage area located on the top of motor housing.

Fig. 5

Fig. 6

Fig. 7

TO DECREASE

TORQUE

TO INCREASE

TORQUE

TORQUE

ADJUSTMENT RING

1

2

BIT

STORAGE AREA