18

OPERATION

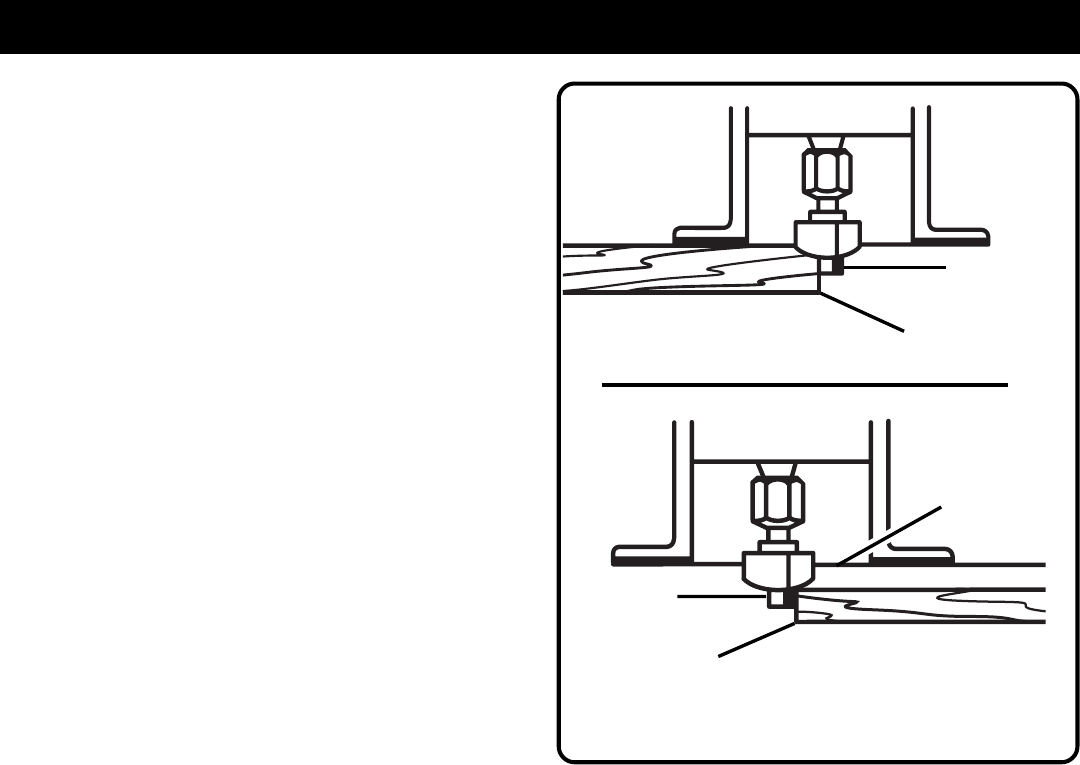

EDGING WITH PILOTS

See Figure 15.

You can cut rabbets and molded edges using piloted

cutters. The pilot, which extends below the cutter, allows

the cutter to turn while the pilot follows the edge of the

workpiece. Some pilots are solid extensions of the cutter.

Others are ball bearing guides that are fastened to the

end of the cutter.

Arbor-type bits with pilots are excellent for quick, easy

edge shaping. They follow workpiece edges that are

either straight or curved. The pilot prevents the bit from

making too deep a cut. Holding the pilot firmly in contact

with the workpiece edge throughout the cut prevents the

cut from becoming too shallow.

Whenever the workpiece thickness together with the

desired depth of cut (as adjusted by router depth setting)

are such that only the top part of the edge is to be

shaped (leaving at least a 1/16 inch [1.6 mm] thick uncut

portion at bottom), the pilot can ride against the uncut

portion, which serves to guide it. However, if the

workpiece is too thin or the bit is set so low that there will

be no uncut edge to ride the pilot against, an extra board

must be placed under the workpiece to act as a guide.

This guide board must have exactly the same contour —

straight or curved — as the workpiece edge. If the guide

is positioned so that its edge is flush with the workpiece

edge, the bit will make a full cut (in as far as the bit

radius). On the other hand, if the guide is positioned as

shown (out from the workpiece edge), the bit will make

less than a full cut — which will alter the shape of the

finished edge.

NOTE: When edge shaping with guides, you can use any

of the piloted bits without a pilot. The size (diameter) of

the pilot determines the maximum cut width that you can

make with the pilot against the workpiece edge. The

small pilot exposes all of the bit; the large one reduces

this amount by 1/16 inch (1.6 mm).

When routing all edges of a panel or board, rout the end

grain first. Any splintering that occurs at the corners will

then be removed when routing the sides. Start each side

1/4 in. (6.35 mm) away from the end. Feed the cutter into

the wood until the pilot contacts the uncut edge. Then,

slowly back the router to shape the corner. Next, move

the router forward to shape the rest of the edge. Be

careful to keep the pilot pressed against the uncut edge.

Repeat this procedure on each side of the panel. Figure

20 shows the proper sequence of cuts to make when

edge routing four sides of a panel.

Fig. 15

PILOT

WORK

WORK

PILOT

TOP EDGE SHAPING

WHOLE EDGE SHAPING

GUIDE

ROUTER

ROUTER