Objective:

In this project, our main objective is to effectively model the Ryobi ® Variable

Speed Reciprocating Saw. It runs through normal 120-V alternating current power. When

on, the saw blade has a stroke of 19/16 inches moving at a maximum speed of 2800

strokes per minute. The entire assembly, including the removable blade, weights 6.3

pounds. The saw has 6 speed settings, a trigger which determines whether the saw is on

or off, and interchangeable blades. After completing the model and assembling it, we will

attempt to animate several aspects of the construction and functions of the saw. Finally,

we will end with an ANSYS analysis of the saw to determine certain limits, for example

under what load the blade would break, and what would be the strongest material through

which the blade can cut.

Challenges:

In undertaking our task, there are many difficulties that arise. First, the saw is

designed for maximum user comfort. That means that the external shell is contoured for

the human hand, with different grips and conveniences. These, as a whole, may be

difficult to model in ProE. A second complexity will be precisely measuring the size of

the pieces to ensure that our assembly comes together correctly. Because of the odd

external shape, some of the internal components are also oddly designed. We must also

take care in disassembling the model so that we do not damage any of the pieces. Finally,

there are approximately 50 different parts to be modeled. Having that many parts to

assemble creates complexities in and of itself.

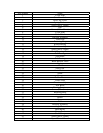

A schematic of the saw follows