Page 10

GENERAL CUTTING

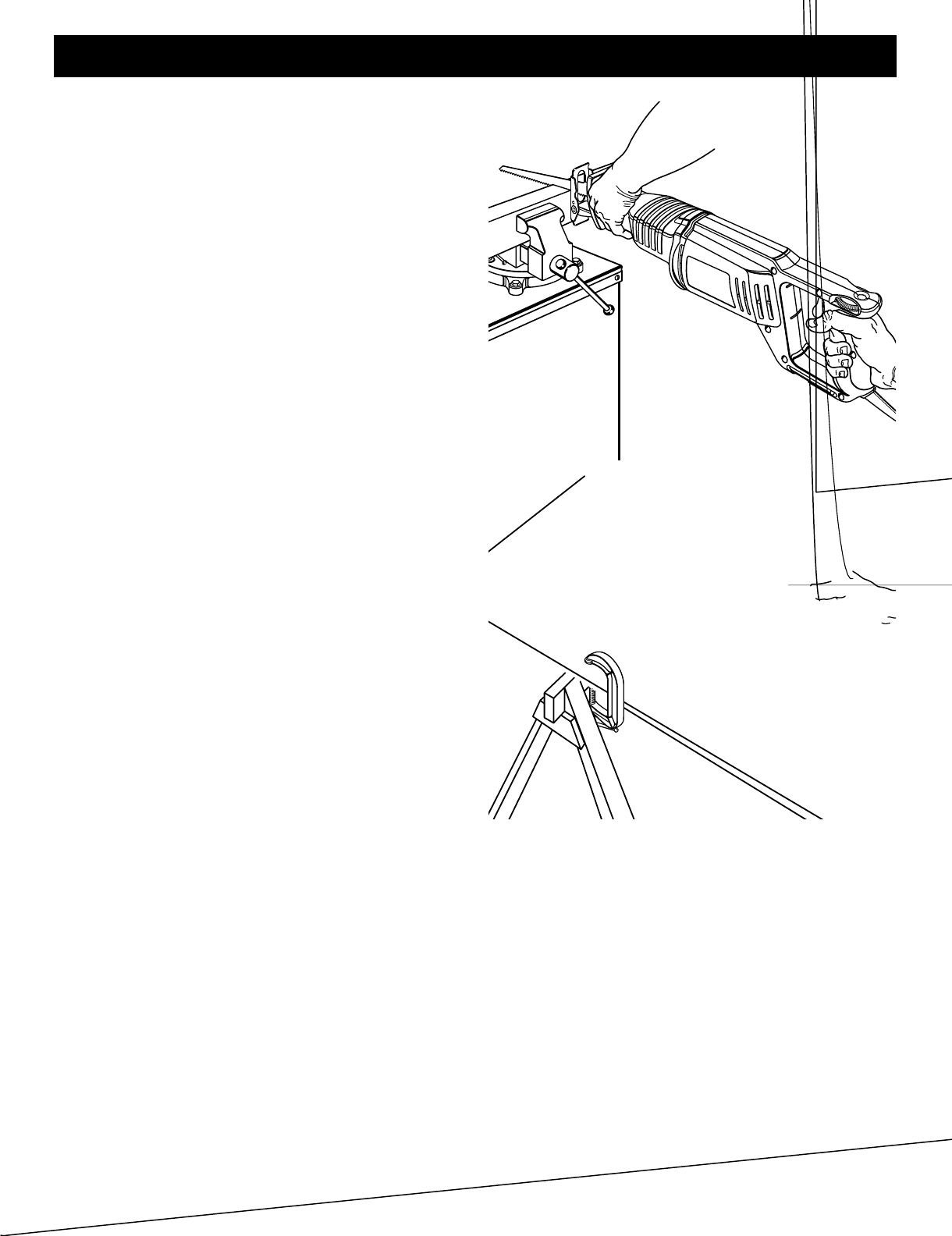

See Figure 7.

Hold your saw firmly in front of and clearly away from you.

Make sure saw blade is clear of any foreign material and that

power cord and extension cord are out of the blade path. Be

sure material to be cut is held firmly. Small work pieces should

be securely clamped in a vise or with clamps to the work

bench or table. Mark the line of cut clearly. Depress the trigger

switch starting the cutting action, set the base assembly

against the work, then move the blade into the work. DO NOT

FORCE. Use only enough pressure to keep the saw cutting.

Let the blade and saw do the work.

PLUNGE CUTTING

See Figure 8.

Mark the line of cut clearly. Choose a convenient starting

point inside the area to be cut out and place the tip of the blade

over that point. Rest front edge of base assembly on work and

hold firmly in position.

WARNING:

Make sure blade does not touch work until motor reaches

full speed, since this can cause loss of control resulting in

serious injury.

With saw blade at full cutting speed, slowly tilt saw downward

until tip of blade starts cutting work. After blade penetrates

work, tilt saw until blade is perpendicular to the work.

OPERATION

METAL CUTTING

See Figure 9.

Metals such as sheet steel, pipe, steel rods, aluminum, brass,

and copper may be cut with your saw. Be careful not to twist

or bend the saw blade. DO NOT FORCE. We recommend

cutting oil when cutting most soft metals and steel. Cutting oil

will also keep blades cool, increase cutting action, and

prolong blade life.

Never use gasoline since normal sparking of motor could

ignite fumes. Clamp the work firmly and cut close to the

clamping point to eliminate any vibration of the work being

cut. When cutting conduit pipe or angle iron, clamp work in a

vise if possible and cut close to the vise. To cut thin sheet

material, "sandwich" the material between hardboard or

plywood and clamp the layers to eliminate vibration and

material tearing.

6