• 13 •

Low vs High Voltage Welding Electrodes

Make certain you have the best electrode for the welding job you intend

to do. Electrode manufacturers make most of the standard welding

electrodes in two basic types. One type has been designed to run on

welders with high Open Circuit Voltage. The other type electrode is

designed to run on welders with Low Open Circuit Voltage. Most of your

welding will probably be done with low open circuit voltage AC rods such

asE-6013orE-7014generalpurposerods.Userodsof1/16,5/64,or

3/32inchdiameter(thethickertherod,themoreexperienceyouneed.)

Highopencircuitvoltagerodssuchas6011,7018,etc.willnotworkwith

mostlowpowerwelders(100ampsandsmaller).

Electrode manufacturers have adopted a uniform marking code for

weldingelectrodes.Eachelectrodeismarkedwithaprexletterandfour

numbers.Eachofthenumbershasaparticularsignicance.Forexample:

a commonly used general purpose electrode is marked E-6013. The E

signiestheelectrodeisforelectricarcapplications.

Thersttwodigitsinthenumberindicatetheminimumtensilestrength,

of the deposited metal, in thousands of pounds per square inch. In this

instance, 60 indicates the melting rod will have a minimum tensile strength

of 60,000 p.s.i. The third number indicates the welding position for which

the rod is intended. A number 1 indicates for use in any position. Number

2representsanelectroderestrictedtoweldinginhorizontalandat

positions.Number3representsanelectrodeintendedforuseintheat

position only. The fourth digit shows some special characteristics of the

electrode such as weld quality, type of current, or amount of penetration.

For all practical purposes, fourth position marking will not affect the rod

you would normally purchase.

Striking The Arc 4.4

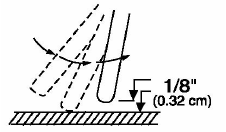

To strike an arc, bring the tip of the rod in contact with the work surface

andthenquicklyraiseituntilthereisabout1/8inch(3.2mm)gapbetween

the rod and the work, as can be seen below.

Theeasiestwaytostrikeanarcistoscratchthetipoftherod(fora

shortdistance)ontheworksurface(asyouwouldstrikeamatch),then

quicklyliftittherequired1/8inch(3.2mm).Itisimportantthatthegap

be maintained during the welding process and that it be neither too wide

or too narrow. If the gap becomes too narrow, the electrode will freeze or

stick to the work piece.