DEPTH OF CUT

As previously mentioned, the depth of cut is important

because it affects the rate of feed which, in turn, affects the

quality of a cut (and, also, the possibility of damage to your

router motor and bit). A deep cut requires a slower feed than

a shallow one, and a too deep cut will cause you to slow the

feed so much that the bit is no longer cutting, it is scraping,

instead.

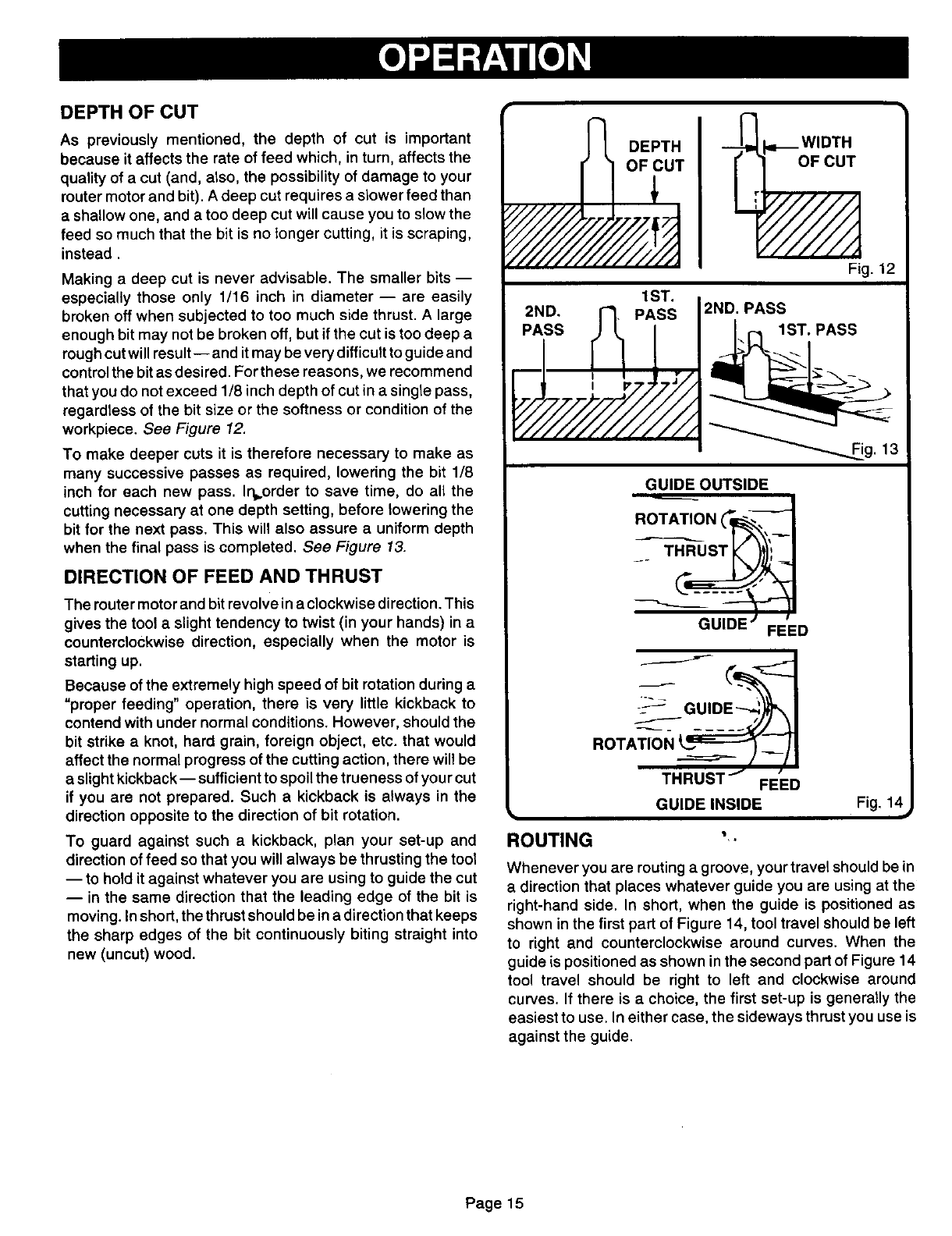

Making a deep cut is never advisable. The smaller bits --

especially those only 1/16 inch in diameter -- are easily

broken off when subjected to too much side thrust. A large

enough bit may not be broken off, but if the cut is too deep a

rough cut will result--and it may be very difficult to guide and

control the bit as desired. For these reasons, we recommend

that you do not exceed 1/8 inch depth of cut in a single pass,

regardless of the bit size or the softness or condition of the

workpiece. See Figure 12.

To make deeper cuts it is therefore necessary to make as

many successive passes as required, lowering the bit 1/8

inch for each new pass. Ir_.order to save time, do all the

cutting necessary at one depth setting, before lowering the

bit for the next pass. This will also assure a uniform depth

when the final pass is completed. See Figure 13.

DIRECTION OF FEED AND THRUST

The router motor and bit revolve in a clockwise direction. This

gives the tool a slight tendency to twist (in your hands) in a

counterclockwise direction, especially when the motor is

starting up.

Because of the extremely high speed of bit rotation during a

"proper feeding" operation, there is very little kickback to

contend with under normal conditions. However, should the

bit strike a knot, hard grain, foreign object, etc. that would

affect the normal progress of the cutting action, there will be

a slight kickback-- sufficient to spoil the trueness of your cut

if you are not prepared. Such a kickback is always in the

direction opposite to the direction of bit rotation.

To guard against such a kickback, plan your set-up and

direction of feed so that you will always be thrusting the tool

-- to hold it against whatever you are using to guide the cut

-- in the same direction that the leading edge of the bit is

moving. Inshort, the thrust should be in a direction that keeps

the sharp edges of the bit continuously biting straight into

new (uncut) wood.

DEPTH

OF CUT

---_, Iq_ WIDTH

r:l-°,cu,

Fig, 12

2ND.

PASS

1ST.

PASS 2ND. PASS

THRUST'J FEED

GUIDE INSIDE

la

ROUTING '_'

Fig. 14

=d

Whenever you are routing a groove, your travel should be in

a direction that places whatever guide you are using at the

right-hand side. In short, when the guide is positioned as

shown in the first part of Figure 14, tool travel should be left

to right and counterclockwise around curves. When the

guide is positioned as shown in the second part of Figure 14

tool travel should be right to left and clockwise around

curves. If there is a choice, the first set-up is generally the

easiest to use. In either case, the sideways thrust you use is

against the guide.

Page 15