9

9

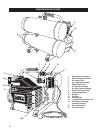

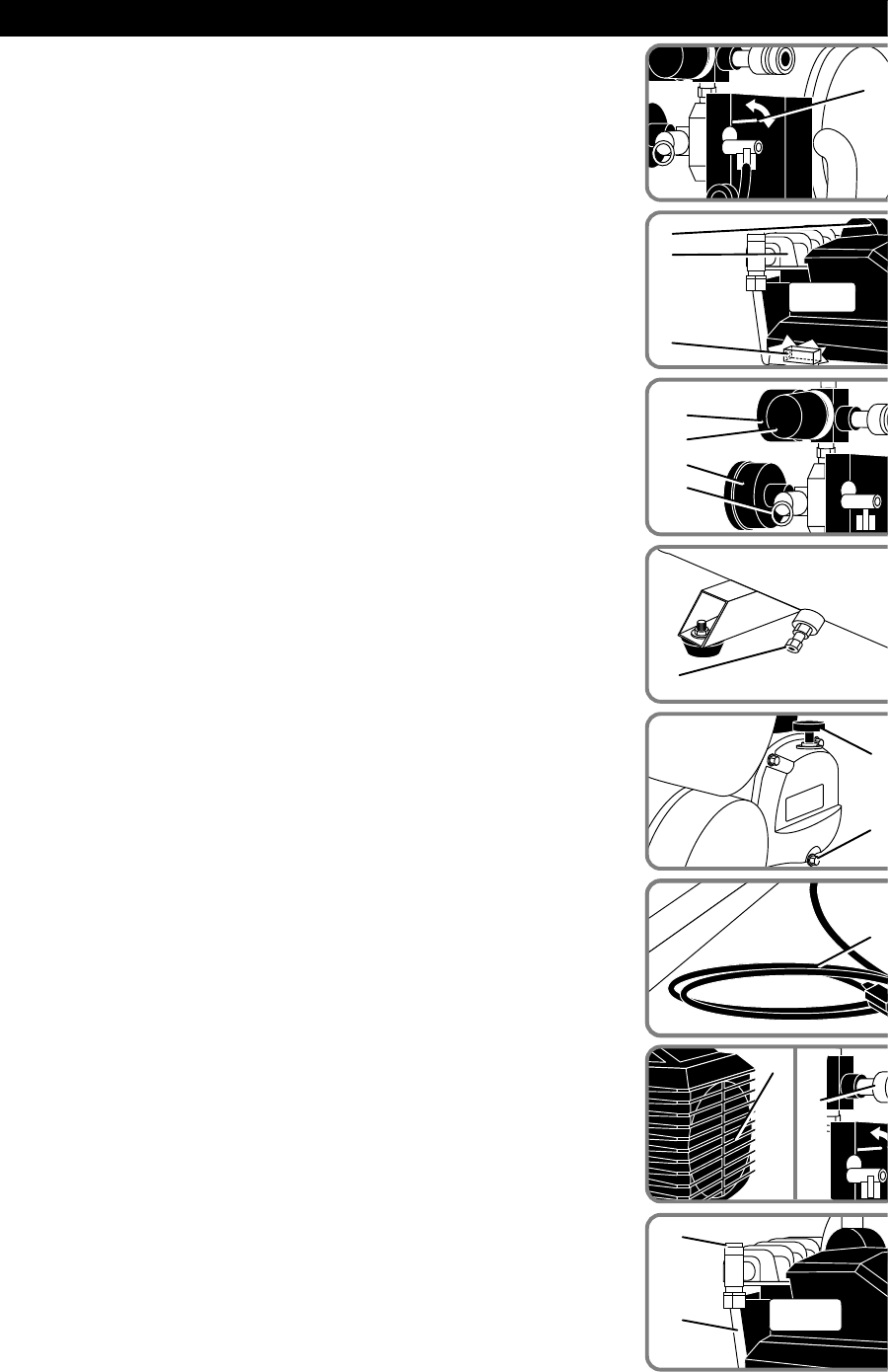

COMPRESSOR FEATURES

1

5

7

9

8

15

10

11

13

16

12

14

6

1) MOTOR/PRESSURE SWIT CH: This switch is used to start or stop the air

compressor. Moving the swit ch to the "Auto" (O n ) position will provi d e automatic power to

the pressure switch which will allow the motor to start when the air tank pressure is below

the factory set "cut-in" pressure. When in the On Position, the pressure switch stops the

motor when the air tank pressure reaches the factory set "cut-out" pressure. For safety

purposes, this switch also has a pressure release valve located below the switch designed

to automatically release compressed air from the air compressor pump head and its

discharge line when the air compressor reaches "cut-out" pressure or is shut off. This allows

the motor to restart freely. Moving the switch to the "Off" position will remove power from

the motor and stop the air compressor.

2) M OTOR THERMAL OVERLOAD: The electric motor has a manual resettable overloa d

protector. If t he motor draws excessive current for any reason, the the rmal overload will

cut off power, thus preventing the motor from being damaged. Wait until the motor is cool

before pressing the reset button to begin working again. If multiple reset result in consistent

trips, check service and/or reference extension cord sizing recommendations.

3) AIR INT AKE FILTER: This filteris designedto clean aircoming intothe pump. Toensure

the pumpcontinually receives aclean, cool,dry air supplythis filter mustalways beclean and

ventilation openingfree from obstructions.The filtercan be removedfor cleaningby using

warm, soapywater. Rinsethe filterand air dry.Replace filter when necessary.

4) AIR COMPRESSOR PUMP: To compress air, the piston moves up and down in the

cylinder. On the downstroke, air is drawn in through the air intake valve while the exhaust

valve remains closed. On the upstroke, air is compressed, the intake valve closes and

compressed air is forced out through the exhaust valve, into the discharge line, through the

check valve and into the air tank.

5) SAFETYRELIEF VALVE: Thisvalve isdesigned to preventsystem failures byrelieving

pressure fromthe systemif compressed air reaches apredeterminedlevel. The valveis preset

by themanufacturer and mustnot bemodified in anyway. To verifythe valveis working

properly, pullon the ring.Air pressureshould escape. Whenthe ring isreleased, itwill reseat.

6) AIR TANK DRAIN VALVE: The drain valve is used to remove moisture from the air

tank(s) after the air compressor is shut off. NEVER attempt to open the drain valve when

more than 10 PSI of air pressure is in the air tank! To open the drain valve, turn the

knob counterclockwise.

7) AIRTANK PRESSURE GAUGE:The airtank pressure gaugeindicates the reserveair

pressure inthe air tank(s).

8) OUTLETPRESSURE GAUGE: Theoutlet pressuregauge indicates theair pressure

available atthe outlet sideof theregulator. This pressureis controlled bythe regulatorand is

always lessor equal tothe airtank pressure.

9) PRESSUREREGULATOR: The airpressure coming from the airtank is controlledby the

regulator knob.Turn the pressureregulation knobclockwise to increase discharge pressure,

and counterclockwise to decrease discharge pressure.

10) OILDIPSTICK: The dipstick will register the amount of oil in the pump. Oil level should

be checked on a daily basis to ensure that it does not exceed the maximum notch or fall

below the minimum notch o n the dipstick. Air escaping from the vent is normal.

11) OILDRAIN: The drain is provided to remove oil that has exceeded its service life. Drain

oil into approved container and dispose of properly. Refill prior to starting.

12) RISKOF BURNS Headand dischargelines can bevery hot.

Do nottouch until unithas cooledafter use.

13) POWERCORD: Use only115VAC 15Aservice. See extensioncord recommendations on

page 10.

14) VENTILATIONOPENING: Keep openingfree ofobstructions to providemaximum

cooling.

15) QUICKDISCONNECT: Spring loadedsealed couplingfor easy hoseremoval. 1/4".

16) COLD START VALVE: The compressor is provided with a normally open valve. This

valve will relieve compressed air for a few seconds at compressor start up allowing the motor

to reach operating speed with low pump resistance.

2

3

4