-9-

M1051 6" Bench Grinder

SET UP

The tool rest supports the workpiece during grinding.

Certain types of grinding may require jigs or accessories

to assure the proper angle of the work piece against the

wheel.

The eye shield must be positioned between the grind

-

ing wheel and your face during grinding. The eye shield

is NOT a substitute for safety glasses or a safety face

shield. You must wear ANSI approved face and eye pro

-

tection.

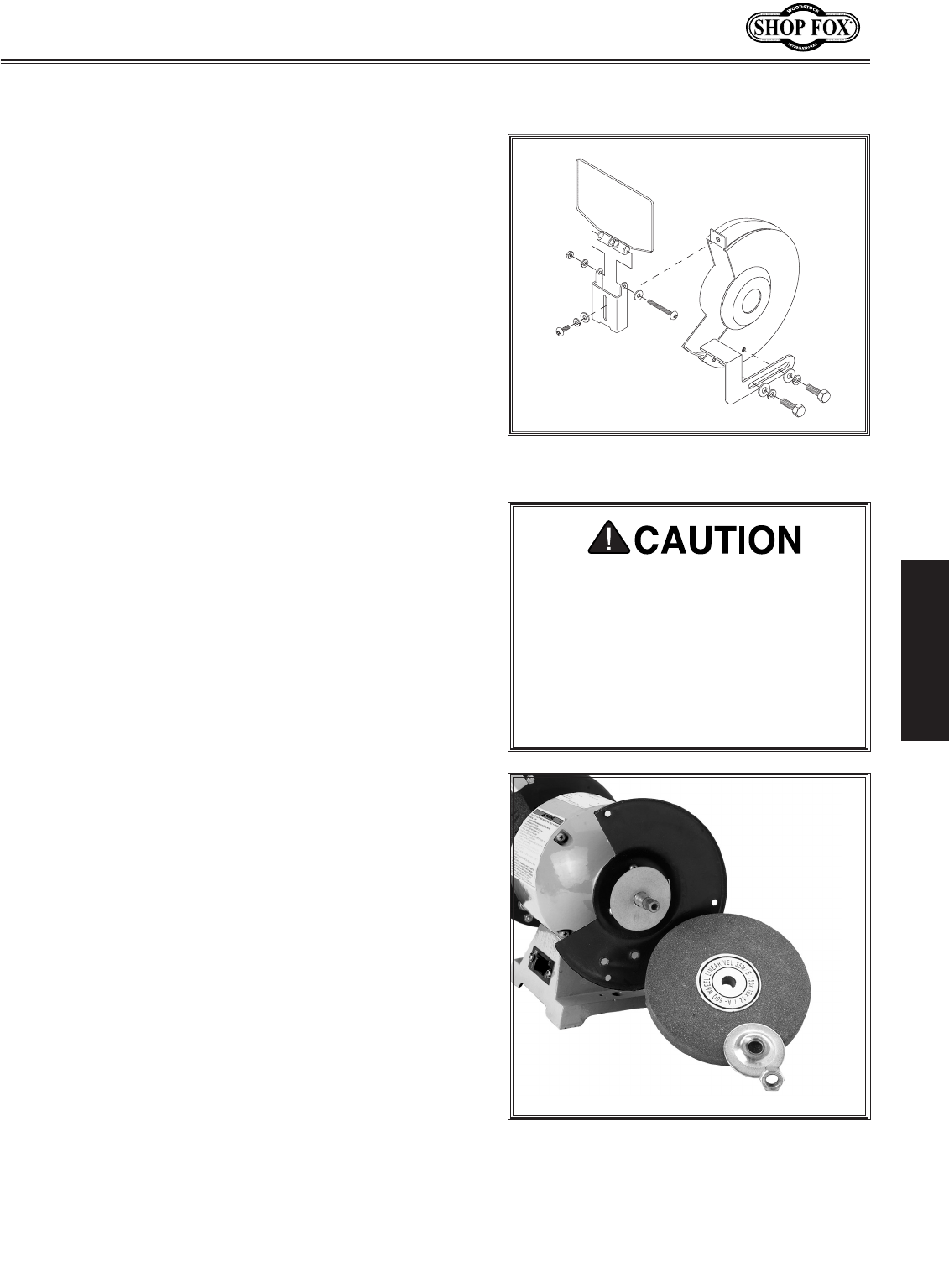

Using the hardware from the

Inventory list on Page 7;

assemble the tool rest and eye shield as they are shown

in Figure 5.

Tool Rest and Eye Shield

Figure 5. Tool rest and eye shield

assembly.

Before installing the included grinding wheels, check

them for integrity by performing a “ring test.” Hang on a

string, then lightly tap the rim of the wheel with a piece

of wood such as the handle of a hammer. The wheel

should have a ringing or harmonic type of sound. If the

wheel responds with a dull thud it may indicate that the

wheel has cracks. Do not use a wheel which is suspected

of having cracks, or if there are visual chips, nicks or

dents in the wheel surface. These discontinuities can

lead to wheel failure causing the wheel to fly apart at

operating speed.

Always be sure to use a wheel that is rated for operating

at speeds equal to or greater than 3450 RPM. Install the

grinding wheel, paper disk, wheel flange, and nut in the

order shown in Figure 6, and then attach the side cover.

Note: The arbor shaft and nut on the left hand side of

the grinder is a left hand thread, so tightening it will

require turning it counterclockwise.

Grinding Wheel

Installation

Figure 6. Wheel installation order.

NEVER assemble a grinding wheel on

the arbor without paper or fiber discs

between the wheel and the flange.

Omitting the discs can put undue stress

on the wheel causing it to crack and

possibly fly apart. ALWAYS “ring test” a

wheel before assembly to make certain

it is sound with no cracks or flaws.