page 7

OPERATION

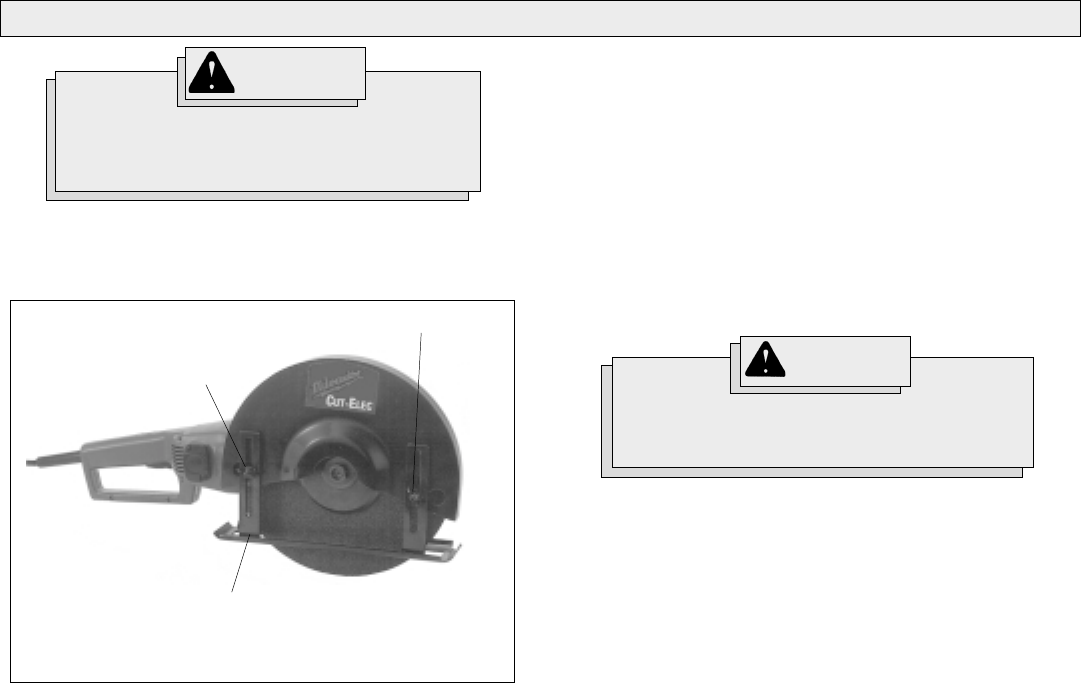

Adjusting the Depth of Cut (Fig. 4)

The shoe assembly can be moved to change the depth of cut. Cut-off

wheels wear down as they are used and the depth of cut may need to

be adjusted.

1. Unplug tool.

2. To change the depth of cut, loosen the wing nuts on shoe assembly

(counterclockwise).

3. Position the depth of the shoe assembly for deeper or shallower

depth (Fig. 4).

NOTE: Make repeated passes at depths of less than 1/2" to achieve

the desired depth. Cutting at a depth of more than 1/2" will damage

the wheel.

4. Tighten the wing nuts securely (clockwise).

NOTE: The MILWAUKEE Hand-Held Abrasive Cut-Off Grinder is de-

signed to cut metal and non-metallic materials. It is NOT recommended

for cutting wood. DO NOT attempt to install a saw blade on the tool. DO

NOT use with liquids or in damp locations.

Starting and Stopping the Tool

The tool operates at no load speed of 4350 RPM.

1. Plug in tool.

2. To start the tool, pull the trigger.

3. To stop the tool, release the trigger.

Preventing Kickback

Kickback is the sudden reaction to a pinched wheel which could cause

a cut-off grinder that is not under control to lift up and out of the work-

piece towards the user. Take the precautions below to help prevent

kickback.

1. Maintain a firm grip and correct body position. Position arms

and body to control the backward and upward reaction force of

kickback. Control the cut-off grinder at all times.

2. Set the depth of cut for no more than necessary. The less

wheel exposed, the less chance of binding and kickback. Before

cutting, be sure shoe assembly is tight.

Wheel Selection

Non-metallic Materials

When cutting non-metallic materials, use a silicone carbide abrasive cut-

off wheel of at least 1/8" thickness which is rated with a maximum safe

operating speed at least 5000 RPM. READ SAFETY INFORMATION SUP-

PLIED WITH CUT-OFF WHEEL. Always wear a dust mask.

WARNING!

Only use abrasive and diamond cutting wheels

with a maximum safe operating speed greater

than the RPM marked on the tool's nameplate.

To reduce the risk of injury, wear safety goggles

or glasses with side shields. Unplug the tool

before changing accessories or making adjust-

ments.

WARNING!

Lower shoe assembly for shallower cuts.

Raise shoe assembly for deeper cuts.

Wing nut

Wing nut

Shoe assembly

Fig. 4

3. Always allow the blade to come to a full stop before remov-

ing the cut-off grinder from the workpiece. Never remove the

cut-off grinder from a cut while the blade is moving. If restarting or

correcting direction in mid-cut, allow the blade to coast to a stop,

back the cut-off grinder up a few inches and center it in the kerf

before restarting.

4. Stay alert. Any distraction can cause twisting or binding. Repetitive

cuts may lull the user into careless movements.

5. Do not force the tool. Forcing a cut-off grinder reduces control

and cutting efficiency.

If kickback should occur, continue to grip the cut-off grinder firmly and

immediately release trigger.

Metallic Materials

When cutting metals, use an aluminum oxide abrasive cut-off wheel of at

least 1/8" thickness which is rated with a maximum safe operating speed

at least 5000 RPM. READ SAFETY INFORMATION SUPPLIED WITH CUT-

OFF WHEEL. Protect everyone in the area from sparks.

Making a Cut

1. Unplug tool. Select a cutting depth and adjust the height of the shoe

assembly as described in Adjusting the Depth of Cut.

2. Plug the tool in and pull the trigger. Allow the motor to reach full

speed and then slowly lower the wheel into the workpiece.

NOTE: Always start the cut gently; do not bang or bump a wheel

when starting the cut.

3. While cutting, keep the shoe flat against the workpiece and maintain

a firm grip. Do not force the cut-off grinder through the work. Forc-

ing a cut-off grinder can cause kickback.

Make repeated passes at depths of less than 1/2" to achieve the

desired depth. Cutting at a depth of more than 1/2" will damage the

wheel. Frequently clean dust from air vents and guards.

4. When the cut is finished, always allow the motor to come to a

complete stop. Never remove the cut-off grinder from a cut while the

blade is moving.

5. If making a partial cut, restarting a cut or correcting cut direction,

allow the wheel to come to a complete stop. To resume cutting,

center the wheel in the kerf (cutting slot), back the saw away from

cutting edge a few inches, pull the trigger and re-enter the cut

slowly.

NOTE: If the cut-off grinder stalls, maintain a firm grip and release

the trigger immediately. Correct the problem before continuing.

Masonry Materials

When cutting masonry materials, use dry diamond wheels or silicone

carbide abrasive cut-off wheel of at least 1/8" thickness which is rated

with a maximum safe operating speed at least 5000 RPM. READ SAFETY

INFORMATION SUPPLIED WITH CUT-OFF WHEEL. Always wear a dust

mask.