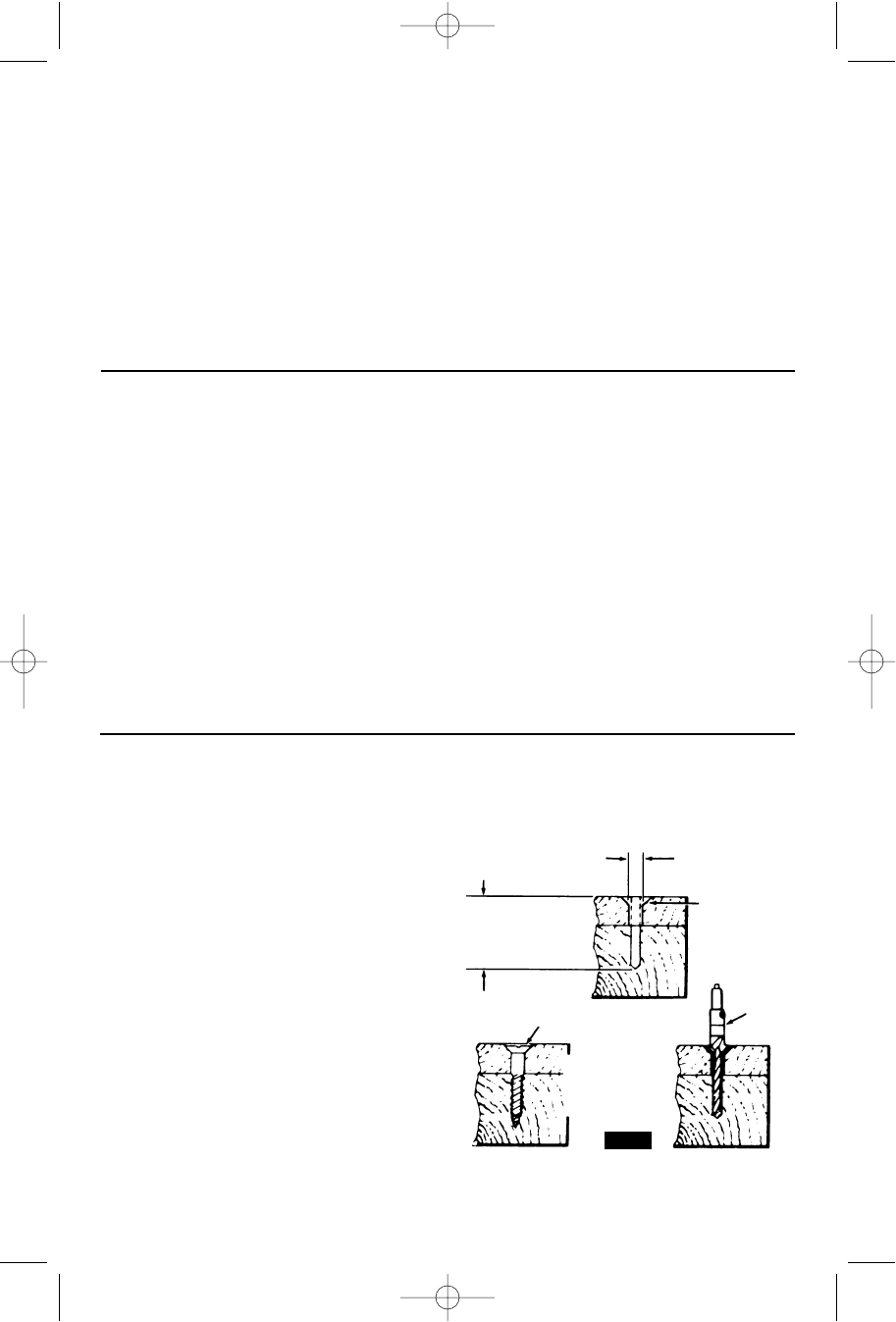

FASTENING WITH SCREWS

The procedure shown in (Fig. 5) will enable

you to fasten materials together with your

hammer drill in the drill mode without

stripping, splitting or separating the material.

First, clamp the pieces together and drill the

first hole 2/3 the diameter of the screw. If the

material is soft, drill only 2/3 the proper

length. If it is hard, drill the entire length.

Second, unclamp the pieces and drill the

second hole the same diameter as the screw

shank in the first or top piece of wood.

Third, if flat head screw is used, countersink

the hole to make the screw flush with the

surface. Then, simply apply even pressure

when driving the screw. The screw shank

clearance hole in the first piece allows the

screw head to pull the pieces tightly

together.

The adjustable screw drill accessory will do

all of these operations quickly and easily.

Screw drills are available for screw sizes No.

6, 8, 10 and 12.

-8-

AUXILIARY HANDLE

(Models 6325 & 6330 only)

The auxiliary handle will provide additional

control, support and guidance for the tool. The

handle is adjustable to any position around the

360° handle collar mount. To mount, slide

handle completely over the handle collar

mount and rotate handle clockwise to tighten

(Fig. 2).

DRILL LEVEL

Your tool is equipped with drill level located on

top of the housing that will allow you to

accurately enter the workpiece in a horizontal

position

(Fig. 1).

USING THE LEVEL: Place drill bit where hole is

to be drilled, position drill so the bubble in the

level is centered between the lines, then start

drilling the hole, once the bit has entered the

workpiece check from time to time to be sure

the bit is maintaining the horizontal position.

You will extend the life of your bits and do

neater work if you always put the bit in

contact with the work before pulling the

trigger. During the operation, hold the tool

firmly and exert light, steady pressure. Too

much pressure at low speed will stall the

tool. Too little pressure will keep the bit from

cutting and cause excess friction by sliding

over the surface. This can be damaging to

both tool and bit.

DRILLING WITH VARIABLE SPEED

The trigger controlled variable speed feature

will eliminate the need for center punches in

hard materials. The variable speed trigger

allows you to slowly increase RPM. By using

a slow starting speed, you are able to keep

the bit from “wandering”. You can increase

the speed as the bit “bites” into the work by

squeezing the trigger.

DRIVING WITH VARIABLE SPEED

Variable speed drills will double as a power

screwdriver by using a screwdriver bit in the

drill mode. The technique is to start slowly,

increasing the speed as the screw runs

down. Set the screw snugly by slowing to a

stop. Prior to driving screws, pilot and

clearance holes should be drilled.

2.Drill same diameter

as screw shank

3.Countersink

same diameter

as screw head

1.Drill 2/3 diameter

and 2/3 of screw

length for soft

materials, full

length for hard

materials

Screw

Apply a slight

even pressure

when driving

screws

Adjustable

Screw

Drill

FASTENING

WITH SCREWS

FIG. 5

Operating Tips

SM 2610912499 2/03 2/10/03 1:43 PM Page 8