-7-

SB1363-64/SB1367-68Mfg. Since 10/09

PREPARATION

Installation

Before installing the rotary

table, make sure that the spindle

centerline is properly aligned or

"trammed" with the mill table. Also,

remove any burrs or scratches from

the mating surfaces of the rotary

and mill table by "stoning" them,

then thoroughly wipe them clean

and dry (refer to the Surface Care

section on Page 16 for detailed

instructions).

Horizontal Installation

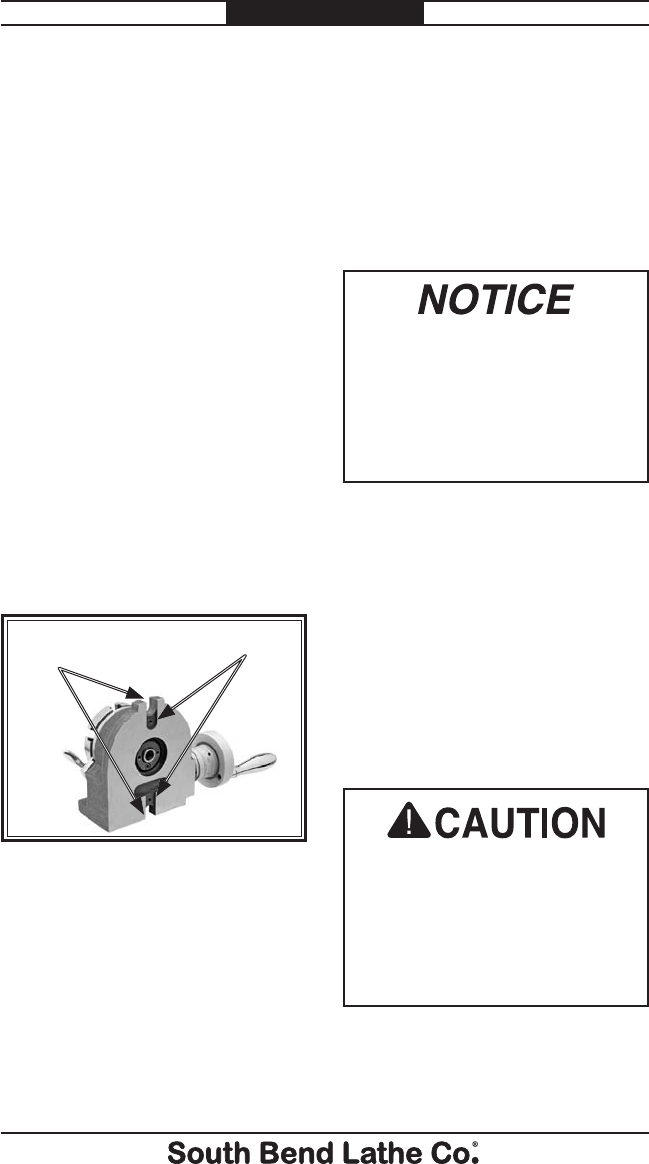

The horizontal base has slots (see

Figure 3) that accept keys for

quick alignment with the mill table.

Because of the many variations in

mill table T-slots, these keys are not

provided with the rotary table. If

you choose to use keys for alignment

when installing the rotary table

horizontally, you will have to

machine them to fit the rotary table

and your mill table.

Figure 3. Locations of the horizontal

base key slots and mounting slots

(Model SB1363 shown).

Mounting

Slots

Key Slots

To mount the rotary table

horizontally:

1. DISCONNECT MILL FROM

POWER!

2. Position the rotary table

horizontally on the mill table so

that the mounting slots shown

in Figure 3 are aligned with the

mill table center T-slot.

You MUST properly secure the

rotary table to the mill table to

prevent unexpected movement

of the rotary table and workpiece

during operation, which could

result in personal injury or

workpiece damage.

5. Perform the Horizontal

Installation Alignment

procedure as instructed on

Page 9.

Make sure the rotary

table handwheel is free of

obstructions. Depending on your

setup, the rotary table may need

to be blocked up or mounted so

the handle is hanging over the

edge of the mill table.

3. Attach the rotary table to the

mill table with the clamping

hardware, but leave the

fasteners loose for now.

4. Placethemachinist'ssquare

along the front edge of the mill

table and the machined foot

of the rotary table, square the

rotary table to the mill table,

then fully tighten the clamping

fasteners.