-30-

For Machines Mfg. Since 8/09

Model SB1021/SB1022

OPERATION

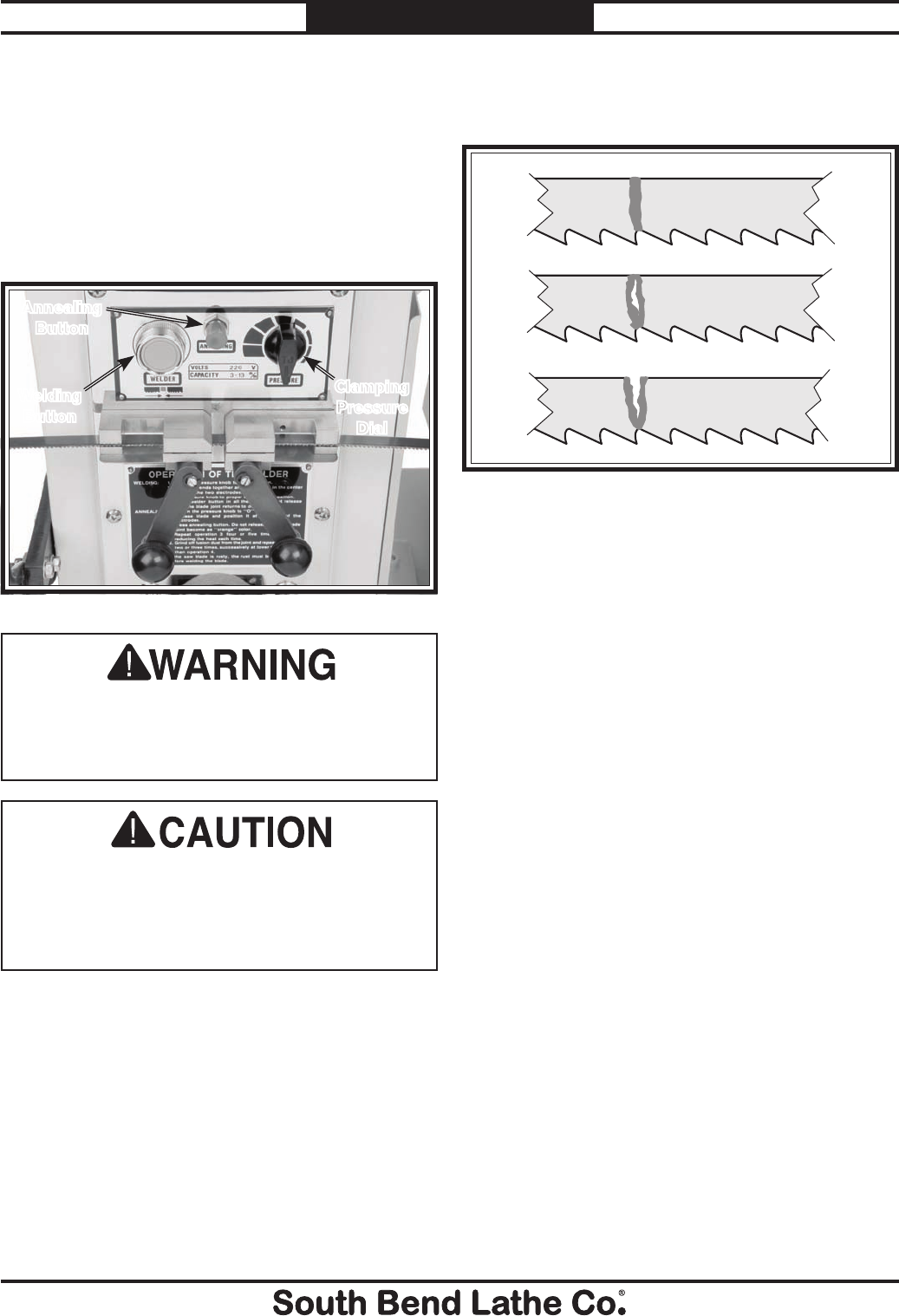

11. Inspect the weld. The welded joint should be

even across the width of the blade with no

gaps (see Figure 30).

Correct

Not Correct

Not Correct

Figure 30. Blade welded joint examples.

— If the weld is satisfactory, continue to

Step 12.

— If the weld is NOT satisfactory, begin

again at Step 2.

12. Place the blade in the welding clamps with

the weld centered between the clamps and

re-tighten the lock levers.

Note: The welding operation leaves the blade

joint brittle. Annealing allows the material

to cool in gradual manner, giving the weld

strength and flexibility. When annealing, the

blade is heated until it turns a specific color

that is determined by the blade material.

The annealing process is unsuccessful (blade

breaks easily) if the weld is not heated

enough or if it is heated too much. For best

results, contact the blade manufacturer for

the proper annealing color.

8. Place the other blade end in the opposite

welding clamp and position it so that it

evenly butts up against the opposing blade

end, then lock it in place by rotating the lock

lever all the way up, as shown in Figure 29.

Note: For a good blade weld, it is critical that the

blade ends evenly butt up against each other

without overlap, gaps, or misalignment.

Light generated during the welding process

could cause serious eye damage. To reduce

your risk, always use eye protection approved

for welding when using the blade welder.

Burning sparks may be thrown in all

directions while welding. Protect yourself from

injury by not welding near flammables and

wearing spark-resistant clothing/gloves. Keep

fire extinguishing equipment readily available.

Figure 29. Blade ends in correct position for welding.

Annealing

Button

Welding

Button

Clamping

Pressure

Dial

9. Press and release the welding button. The

blade ends will be welded together.

10. Rotate the lock levers down to release the

welding clamps, then rotate the clamping

pressure dial to "0".