For Machines Mfg. Since 3/11 16-Speed Gearhead Lathe

-83-

SERVICE

4. Put on safety glasses.

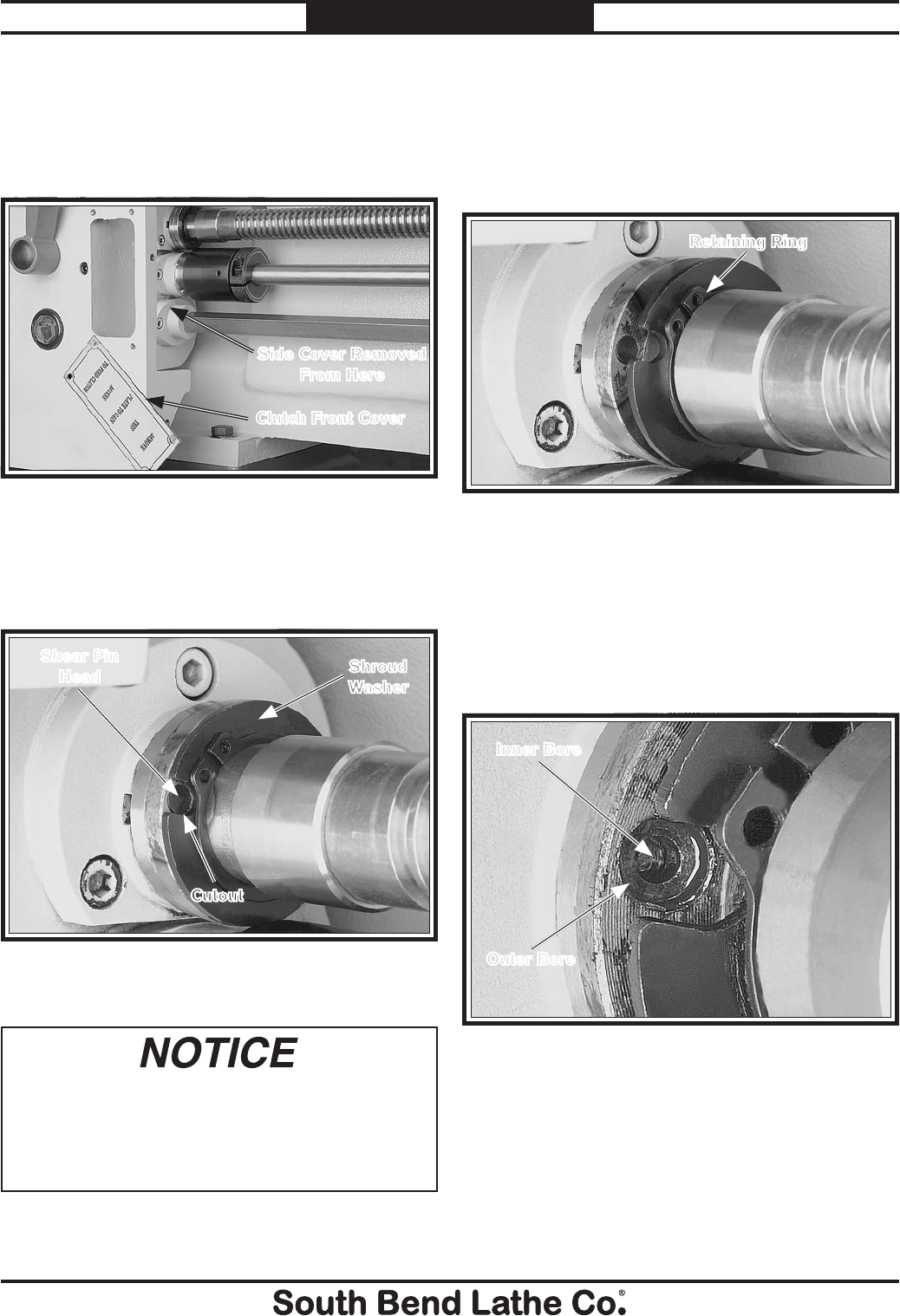

Figure 140. Shroud washer and shear pin alignment.

Cutout

Shear Pin

Head

Shroud

Washer

3. Rotate the shroud washer on the leadscrew

(see Figure 140) so that the cutout lines up

with the shear pin head.

5. Move the retaining ring shown in Figure

141 away from the shroud washer, then

move the shroud washer away from the

shear pin and against the retaining ring.

This will create room for you to remove the

shear pin.

Figure 141. Shear pin access.

Retaining Ring

6. Use the magnet to remove the shear pin

head.

7. Rotate the lathe spindle to line up the inner

and outer bores, as shown in Figure 142,

and use the magnet to remove the other half

of the broken shear pin.

Figure 142. Shear pin bores aligned.

Outer Bore

Inner Bore

If you fabricate your own shear pin, make sure

to use the material and dimensions specified

in Figure 138. Otherwise, the shear pin may

not provide the intended protection and lathe

damage could result.

To replace the shear pin:

1. DISCONNECT LATHE FROM POWER!

2. Remove the clutch front and side covers (see

Figure 139).

Figure 139. Location of clutch front cover (side cover

removed for photo clarity).

Clutch Front Cover

Side Cover Removed

From Here