13

Check the chain adjustment bolts and secure the nuts if

required.

Check the Housing Cover plate bolts and tighten if needed.

Check the hydraulic hoses, ttings and valves for any leaks

and repair as required.

With the machine turned off, oil the chain over the top sprocket

with a heavy duty gear oil such as Mobil Gear 600 Series.

Refer to the table below for recommended chain oil.

Ambient Temperature Lubricant Rating (SAE)

Viscosity Grade

(Hydraulic Fluid)

23° - 41°F / -5° - +5°C 20 46 - 68

41° - 104°F / 5° - 40°C 30 100

104° - 122°F / 40° - 50°C 40 150 - 220

122° - 140°F / 50° - 60°C 50 320

MONTHLY CHECK

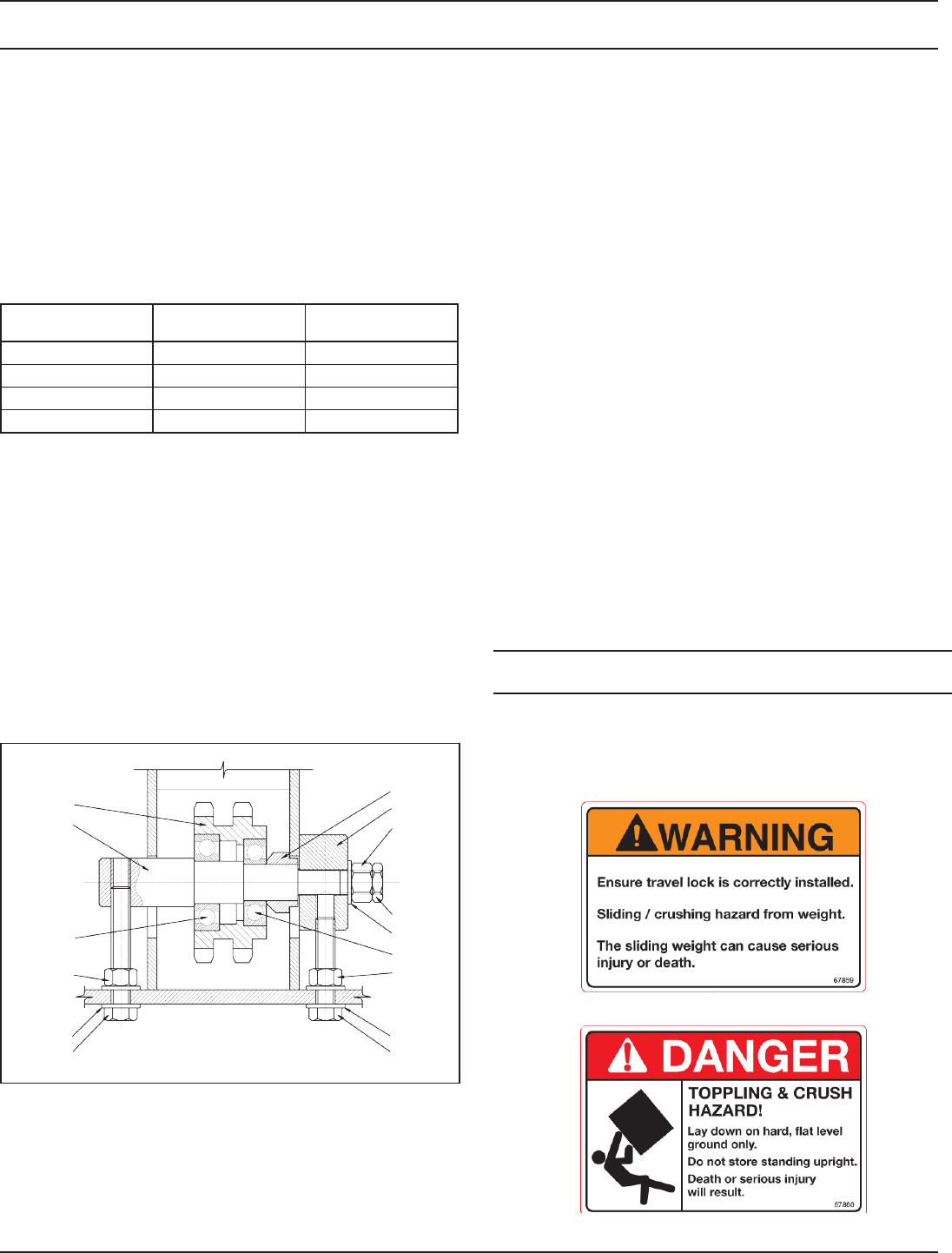

With the drop hammer in a vertical position and the carrier

turned off remove the Housing Cover plate. Check the chain

tension. The chain should move about 1/2 inch/10-15 mm at

its center point. To adjust the chain, loosen the Tensioning

Bolt lock nuts (Item 32 DH1500 or Item 30 DH3500) and the

Clamp Nut (Items 41-42 DH1500 or Items 34-35 DH3500).

Adjust the Tension Bolts evenly (so that the lower shaft/

sprocket are kept parallel). See Figure 4 below.

Note: In the rst month of operation this should be

done weekly until the chain beds in.

Figure 4. Lower Sprocket Assembly

Remove the rubber inspection cover at the top of the drop

hammer and check the motor nut is tight. Replace the

inspection cover.

Lower

Sprocket

Shaft

Bearing

Nut

Washer

Hex Head Setscrew

(Long)

Hex Head Setscrew

(Short)

Washer

Nut

Bearing

Washer

Half Nut

Nut

Adjuster

Bracket

Sprocket

Spacer

OPERATION

Standing clear of the machine, start the drop hammer and

SLOWLY rotate the chain until the chain Connecting Plate

Assembly is accessible. Turn the carrier off and disconnect

hydraulic hoses.

Check this assembly for signs of excessive wear, and replace

as required.

Lubricate this assembly and the chain. Refer to the table on

the previous page.

Replace the Housing Cover.

Tip the drop hammer forward and slide the weight out as

described Adjusting Impact section of this manual.

Inspect the Hammer Connecting Pin and replace if excessively

worn.

Liberally grease the Hammer Connecting Pin USE A LITHIUM

BASED GREASE WITH NGLI 1 or 2 RATING (Mobilgrease

HP or Shell Alvania EP) and replace the hammer as described

in Adjusting Impact section of this manual.

It is worthwhile at this stage to dress the hammer tip and

remove any excessive burring.

TRAVEL AND STORAGE

1. Ensure the travel lock is installed before transporting the

drop hammer.