11

OPERATION

NOTICE

Failure to remove the travel lock may result in damage

to the equipment during operation.

Exposure to silica dust during construction activities

can cause serious or fatal respiratory disease. Use

adequate respiratory protection.

OPERATION

Ensure that the drop hammer is operated at a safe distance

from other personnel and equipment. Be sure all guards are

in place.

The drop hammer's weight is normally rested on the skids

during use. However when moving about the drop hammer

may represent a heavy load for the carrier. Therefore care

must be taken when moving about a job-site or when loading

or unloading from a transporter. The drop hammer should be

carried as low as possible and special care taken when nego-

tiating uneven surfaces. Know the limits of your carrier.

NOTICE

The drop hammer is intended for use only on level or near

level surfaces. Do not operate the drop hammer on uneven

or unlevel surfaces.

MOUNTING TO THE CARRIER

1. With the drop hammer laying on a at level surface bolt the

mounting plate to the mounting bracket. Ensure these bolts

are torqued to the recommended value.

2. Bring the carrier up to the drop hammer from the bottom or

impact end. If you have a quick attachment systems maneuver

the mount plate on the carrier until it engages with the adaption

plate. Then actuate the slides or levers to lock the plates

together. With a pin mount system; maneuver the carrier until

the pinholes are aligned and slide in the connection pins.

Ensure the pins are bolted in place. Grease these pivots as per

the carrier manufactures recommendations. Never operate

the drop hammer with a loose or ill-tting attachment.

Connect the hoses to supply oil to the port marked "PRESS"

on the valve block.

3. Carefully raise the drop hammer to the vertical position

keeping the base of the machine close to the ground

throughout the lifting movement. Slowly move the Cyclone

through the full extent of rotation and lift to ensure no part of

the machine or any hydraulic hosing foul the carrier arms or

cylinders. Ensure hoses are long enough so they do not pull

tight in any part of the rotation and short enough to stay clear

of the ground or operating area.

4. Once the drop hammer is securely mounted to the carrier

the Traveling Lock may be removed. Be sure to store this

plate safely for future use.

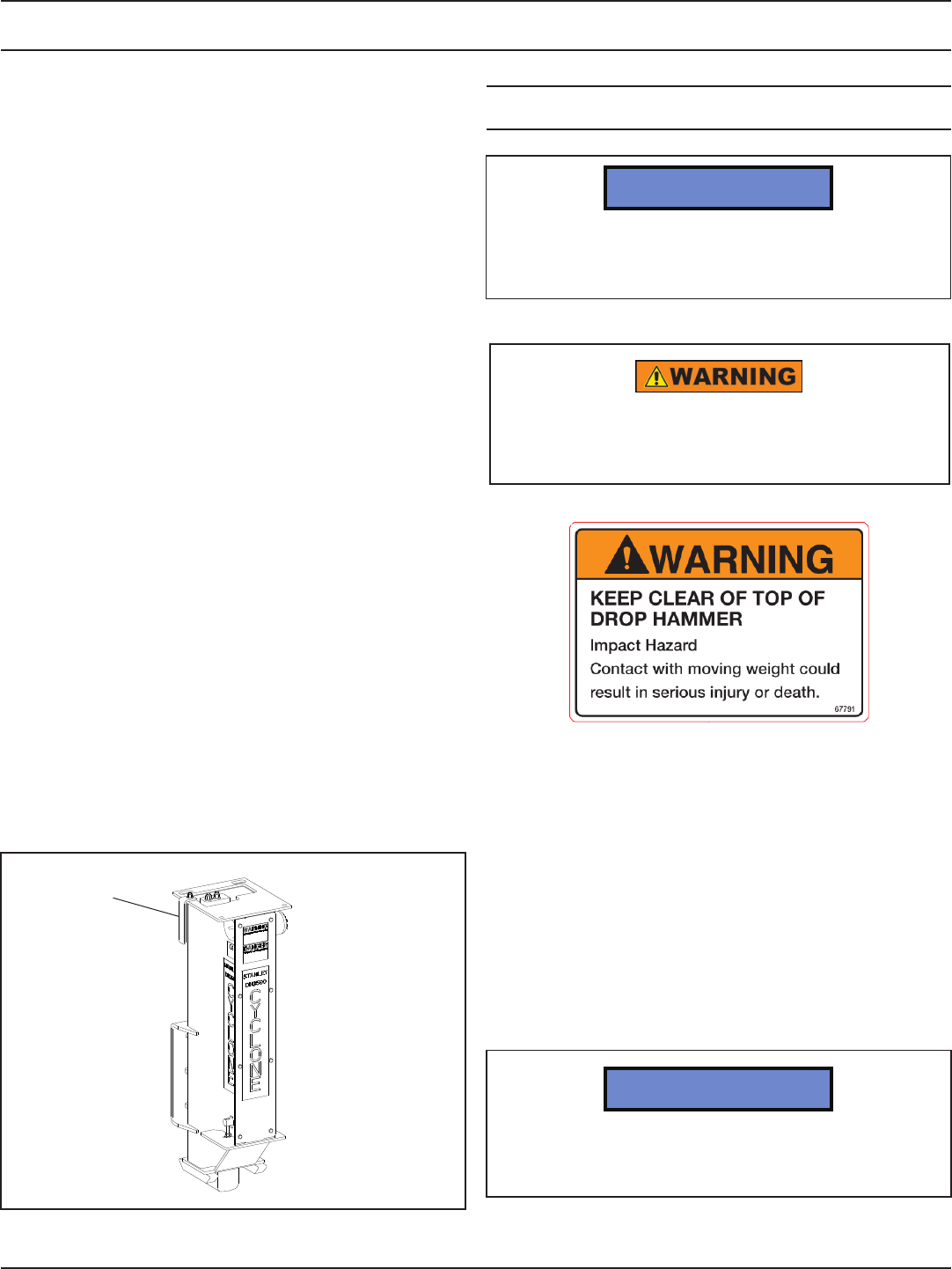

During use, the traveling lock may be bolted outside the

housing using the same hole as shown in Figure 2 below.

OPERATION

Figure 2. Traveling Lock

Traveling Lock