ADJUSTING THE BTFP12180/BTFP12181

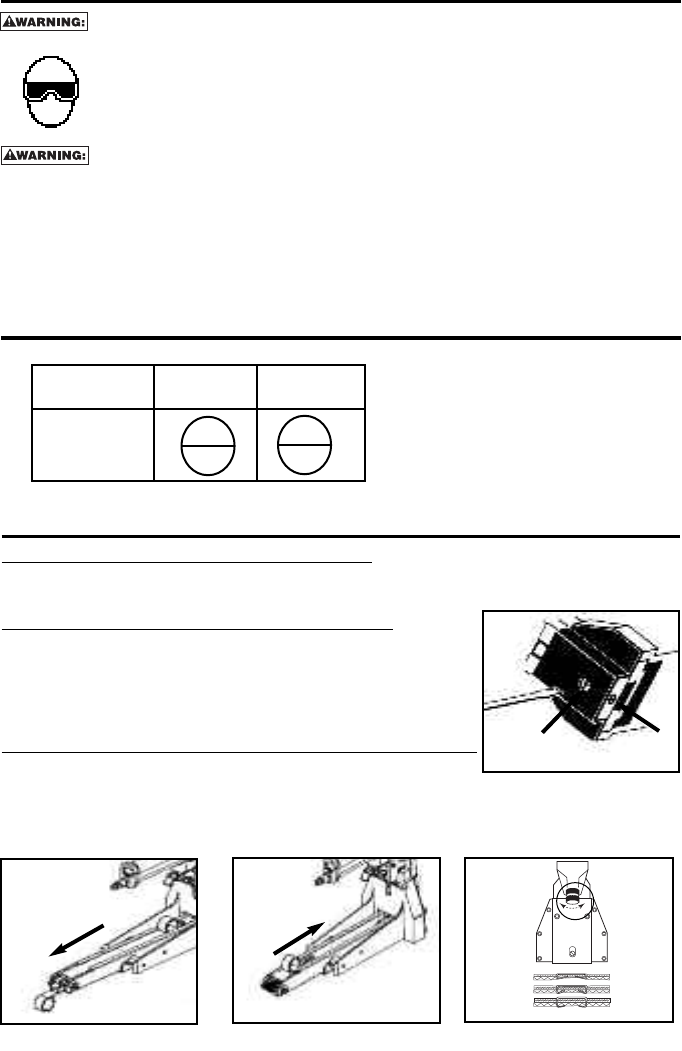

STAPLE SELECTOR (ALL MODELS) (FIG 1)

To adjust the tool for different leg lengths, loosen set-screw (A) and turn dial 180° (B) with a screwdriver

to the desired position as noted in the tables at the front of this manual. Tighten set-screw.

LOADING THE TOOL - BTFP12180/BTFP12181

A) Pull the pusher to the back of the magazine. (Fig 2)

B) Check Staple Leg Length: Adjustment is provided for

different staple leg lengths (see section below).

C) Insert 2 sticks of staples into the channel and gently

release the pusher against the staples. (Fig 3)

CLINCH ADJUSTMENT - BTFP12180/BTFP12181 (FIG 4)

Turn special nut (A) through window clockwise to tighten clinch

and counter-clockwise to loosen clinch. Use a tool to fit 1/8” (3mm)

LOADING THE BTFP12180/BTFP12181

E

YE PROTECTION which conforms to ANSI specifications and provides protection against

f

lying particles both from the FRONT and SIDE should ALWAYS be worn by the operator and

others in the work area when connecting to air supply, loading, operating or servicing this

tool. Eye protection is required to guard against flying fasteners and debris, which could

cause severe eye injury.

T

he employer and/or user must ensure that proper eye protection is worn. Eye protection

equipment must conform to the requirements of the American National Standards Institute,

A

NSI Z87.1 and provide both frontal and side protection. NOTE: Non-side shielded

spectacles and face shields alone do not provide adequate protection.

TO PREVENT ACCIDENTAL INJURIES:

• Never place a hand or any other part of the body in discharge area of tool while

the air supply is connected.

• Never point the tool at anyone else.

•

Never engage in horseplay.

• Never pull or depress the actuating lever unless nose is directed at the work.

• Always handle the tool with care.

• Do not depress the actuating lever while loading the tool.

TOOL ADJUSTMENT CHART

FIG.4

-4-

S

L

S

L

5/8" (15mm) 3/4" (19mm)

STAPLE

LENGTHS

DIAL

POSITION

FIG.1

FIG.2

FIG.3

A

B