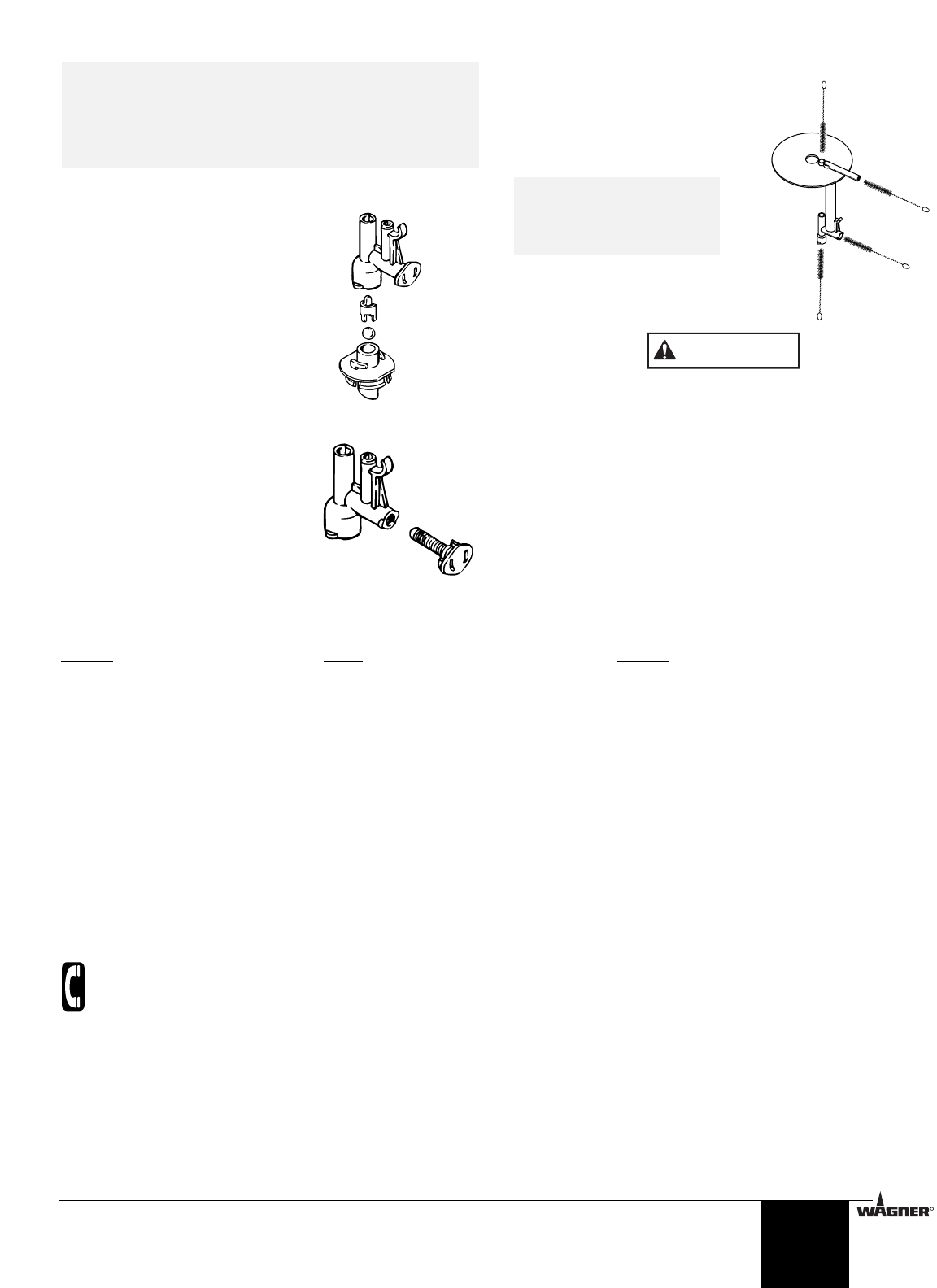

Cleaning the Valves

Cleaning the Inlet Valve

1. Press down on the locking

tab and pull the valve

assembly out.

2. Turn valve body

counterclockwise and remove.

3. Remove the ball retainer and

inlet ball.

4. Remove the filter basket and

thoroughly clean all parts in

warm, soapy water or the

appropriate solvent.

Cleaning the Outlet Valve

1. Turn valve cap assembly counter

clockwise remove.

2. Clean all parts in warm, soapy

water or the appropriate solvent.

Cleaning the Pump Housing

1. Clean pump housing with warm,

soapy water or the appropriate

solvent using the brush supplied.

2. Apply a thin layer of petroleum

jelly to the pump O-Ring.

Storing the Roller

Clean, dry, and lubricate the system thoroughly before storing.

Do not store with liquids inside unit. Storing the unit in cold

temperatures can cause the liquids to freeze and expand,

causing pressure to build and break parts. Let the equipment

come up to room temperature before operating.

When storing the roller for more than a day, take the following

precautions:

1. Remove the batteries.

2. Remove the hose from the pump fitting.

3. Store the hose in a large loop. If it is bent, it could be damaged.

CAUTION

NOTE: Be sure to clean all

small parts

thoroughly. Paint will

act as an adhesive

when dry.

NOTE: Remove the pump carefully or the piston may come off.

If the piston comes off, reassemble by sliding piston

onto the brass piston connecting rod.

NOTE: Wipe excess paint off the drive housing with an

appropriate solvent. DO NOT IMMERSE UNIT IN

SOLVENT OR OTHER LIQUID.

R

©1997 Wagner Spray Tech. All rights reserved. 5

English

Troubleshooting

Problem Cause Solution

The pump will not run. There is little or no power. Put in new high quality alkaline batteries.

The batteries are not in properly. Put the batteries in properly.

The pump on/off button was not pressed. Press and release the pump on/off button.

The pump has seized up. Clean the piston and pump housing.

The motor and piston run but The batteries are low. Put in new high quality alkaline batteries.

there is little or no fluid flow. The fluid hose is leaking. Tighten the fluid hose securely.

The inlet, outlet, or relief valves are dirty. Clean the inlet and outlet valves.

The fluid in the fluid tank is low. Fill the fluid tank.

The piston O-ring is worn. Replace the piston O-ring.

The piston has slipped off the brass axle. Snap the piston back on the axle

Paint leaks from the roller core. The seal is not in place. Check and place the seal properly.

Roller cover slides on the wall. Too much paint pumped to roller. Press and release the pump on/off button to turn the

the pump off until more paint is needed.

The seal is not lubricated. Remove the seal, lubricate and replace.

Have you tried the recommendations above and are still having problems? In the United States, call our toll-free

consumer service at 1-800-328-8251 Monday through Friday between 8:00 AM and 4:30 PM Central time or between 9:00

AM and 4:00 PM Saturday or Sunday, or contact an authorized service center.