1 of 6

For technical questions and replacement parts, please call 1-800-222-5381.

Thank you very much for choosing a , Product! For future reference, please

complete the owner's record below:

Model: _______________ Purchase Date: _______________

Save the receipt, warranty and these instructions. It is important that you read the entire

manual to become familiar with this product before using it.

This machine is designed for certain applications only. strongly

recommends that this machine is not modified and/or used for any application other than

that for which it was designed. If you have any questions relative to a particular

application, DO NOT use the machine until you have first contacted Northern Tool +

Equipment to determine if it can or should be performed on the product.

Before using this product, please read the following instructions carefully.

SAVE THIS MANUAL

You will need this manual for the safety warnings and precautions, assembly, operating,

inspection, maintenance and cleaning procedures, parts list and assembly diagram. Keep

this manual and invoice in a safe and dry place for future reference.

GENERAL SAFETY RULES

Read and understand all instructions.

Failure to follow all instructions listed in the following pages may result in electric shock,

fire, and/or serious injury.

WORK AREA

1.Keep your work area clean and well lit. Cluttered benches and dark areas invite

accidents.

2.Do not operate pneumatic tools in explosive atmospheres, such as in the

presence of flammable liquids, gases, or dust. Pneumatic tools create sparks which

may ignite flammables.

3.Keep bystanders, children, pets and onlookers away while operating a pneumatic

tool. Distractions can cause you to lose control. Protect others in the work area from

debris such as metal filings and sparks. Provide barriers or shields as needed.

Wel-Bilt

The distributor

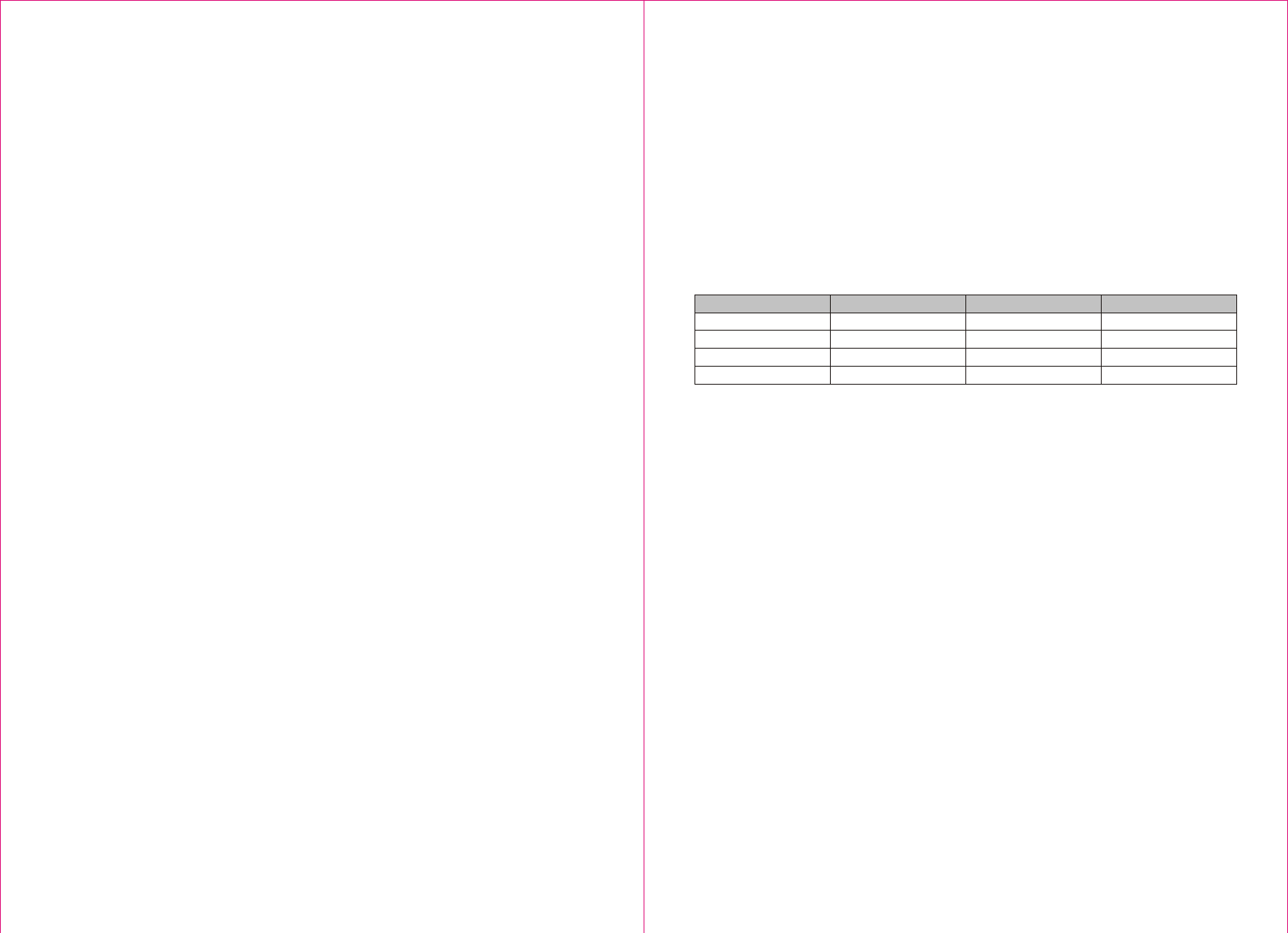

TECHNICAL SPECIFICATIONS

PERSONAL SAFETY

1.Stay alert. Watch what you are doing, and use common sense when operating a

pneumatic tool. Do not use a pneumatic tool while tired or under the influence of drugs,

alcohol, or medication. A moment of inattention while operating pneumatic tools may

result in serious personal injury.

2.Dress properly. Do not wear loose clothing or jewelry. Contain long hair. Keep your hair,

clothing, and gloves away from moving parts. Loose clothes, jewelry, or long hair can be

caught in moving parts.

3.Avoid accidental starting. Be sure the trigger is off before connecting to the air

supply. Carrying pneumatic tools with your finger on the trigger, or connecting pneumatic

tools to the air supply with the trigger on, invites accidents.

Item

Square Drive

Free Speed

Max. Torque

Air Consumption

Description

1/2in.

7000 RPM

230 ft-lbs

8 CFM

1/4in.- 18NPT

3/8in.

90 PSI

Description

Air Inlet Diameter

Min. Hose Size

Max. air pressure

Item

TM

4 of 6

INSPECTION, MAINTENANCE AND CLEANING

1.Always make sure the trigger is in its "OFF" position, and disconnect the tool from its

compressed air supply before performing any inspection, adjustments, maintenance, or

cleaning.

2.Before each use, inspect the general condition of the tool. Check for loose screws,

misalignment or binding of moving parts, cracked or broken parts, damaged air hose, and

any other condition that may affect its safe operation. If abnormal noise or vibration

occurs, have the problem corrected before further use. Do not use damaged equipment.

3.Daily: With a clean cloth, remove all dirt, oil, and grease from the tool. If necessary, you

may use a mild detergent. Do not use solvents, as damaged to the tool may occur. Do not

immerse the tool in any liquids.

GENERAL TOUBLE SHOOTING

l TROUBLES

ØTool does not run at a normal speed or at a variable speed

ØThe motor blocks

ØAutomatic start when connected to compressed air

ØTorque reduces

ØAbnormal vibrating Heat rising at the housing

l CAUSES

ØAir supply is not enough (air pressure not in a required standard)

ØSpeed controller/switch breaks down

ØRotor blades break or wear out

ØDust gets into the motor

ØThrottle lever or starting trigger malfunctions

ØAir leakage at the inlet or somewhere else

ØBearing damages

ØCorrespondent O-rings wear out or out of position

ØLack of lubricating

l TROUBLE SHOOTING

ØCheck the air hose to see whether it is blocked or twisted for less air supply

ØCheck the air compressor to gain the correct air pressure required

ØReplace rotor blades

ØDisassemble the tool and clean the inner structure under proper instructions

ØCheck and fix the throttle lever or starting trigger for accurate operation

ØCheck the air leakage and fix it under proper instruction

ØReplace new bearing

ØReplace the damaged O-ring or put it back in correct position

ØOil/Lubricate the tool consistently until it gains the right speed and torque.

l NOTE: For any other problems that cannot be corrected by the operator, please

contact the distributor from whom you purchased the tool.