3

INSTALLATION (cont’d)

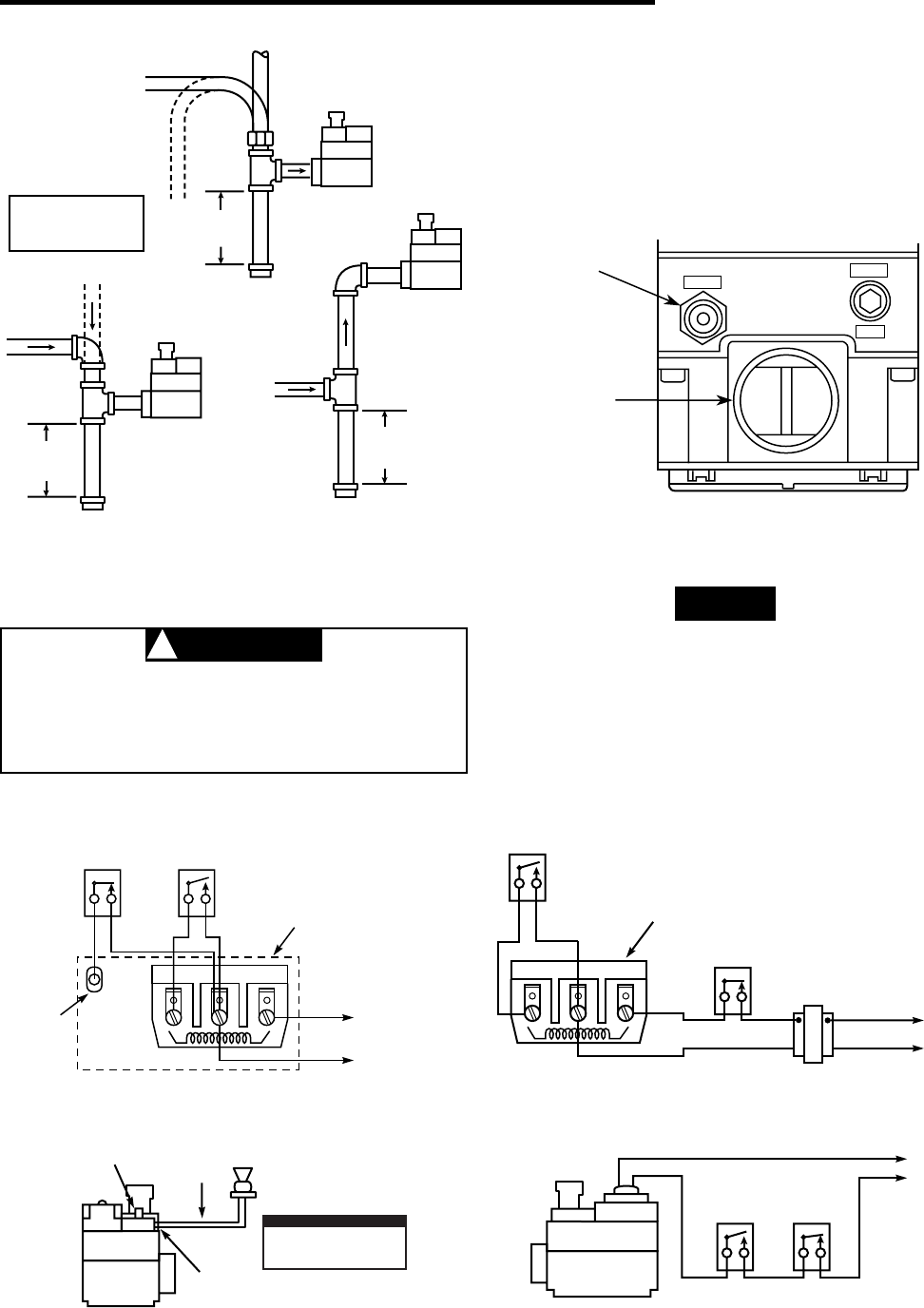

PILOT GAS CONNECTION

Install fitting into pilot gas outlet (see fig. 2), turning until

finger-tight. Insert clean, deburred tubing all the way

through the fitting. While holding the tubing securely,

slowly tighten fitting until you feel a slight "give". Tighten

the fitting an additional 1 1/2 turns.

SYSTEM WIRING

To prevent electrical shock and/or equipment dam-

age, disconnect electrical power to system at main

fuse or circuit breaker box until installation is

complete.

All wiring should be installed in accordance with local

and national electrical codes and ordinances.

Always check that the electrical power supply used agrees

with the voltage and frequency shown on the gas control.

The typical wiring diagram shows only the terminal iden-

tification and wiring hook up. Always refer to wiring

instructions provided by Equipment Manufacturer for sys-

tem hookup operation.

CAUTION

!

NOTE

Line voltage

operating

control

Line

Gas valve

High

limit

Figure 6. Wiring for 36C03A/36C13A (120 Volt)

Pilot gas

outlet

Gas outlet

PILOT

PRESS

TAP

Figure 2. Gas valve side view

High

Limit

TH TH-PG PG

Thermostat

White-Rodgers

36C Gas Valve

Power

Unit

To Pilot

Generator

Figure 3. Wiring for 36C03U/36C13U/36D34U (.750 Volt)

Gas valve

terminal panel

Figure 4. Wiring for 36C03/36C13 (24 Volt)

TH TH-TR TR

Line

24 VAC

Hot

Transformer

Thermostat

High

limit

Thermocouple

Connection

E.C.O. Device

on Appliance

Lead

Assembly

E.C.O.

Terminals

Figure 5. Wiring for Energy Cut-Off (E.C.O.) connection

NOTE

If appliance does not have

any E.C.O. device, jumper

E.C.O. terminals.

Horizontal

Drop

Piped Gas

Supply

Gas Valve

3 in.

minimum

Gas Valve

Riser

Piped Gas

Supply

3 in.

minimum

Drop

Horizontal

Riser

Gas Valve

Tubing Gas

Supply

3 in.

minimum

NOTE:

Always Include

A Drip Leg In Piping

Figure 1. Typical gas valve piping