6

A B C

D E

General electrical cautions

The drill press should be grounded in accordance

with the National Electrical Code and local codes

and ordinances. This work should be done by a

qualified electrician. The drill press should be

grounded to protect the user from electrical shock.

Wire sizes

Caution: for circuits which are far away from the

electrical service box, the wire size must be

increased in order to deliver ample voltage to the

motor. To minimize power losses and to prevent

motor overheating and burnout, the use of wire sizes

for branch circuits or electrical extension cords

according to the following table is recommended.

AWG (American wire gauge) number

Conductor length 240 volt lines 120 volt lines

0-50 feet No. 14 No. 14

50-100 feet No. 14 No. 12

Over 100 feet No. 12 No. 8

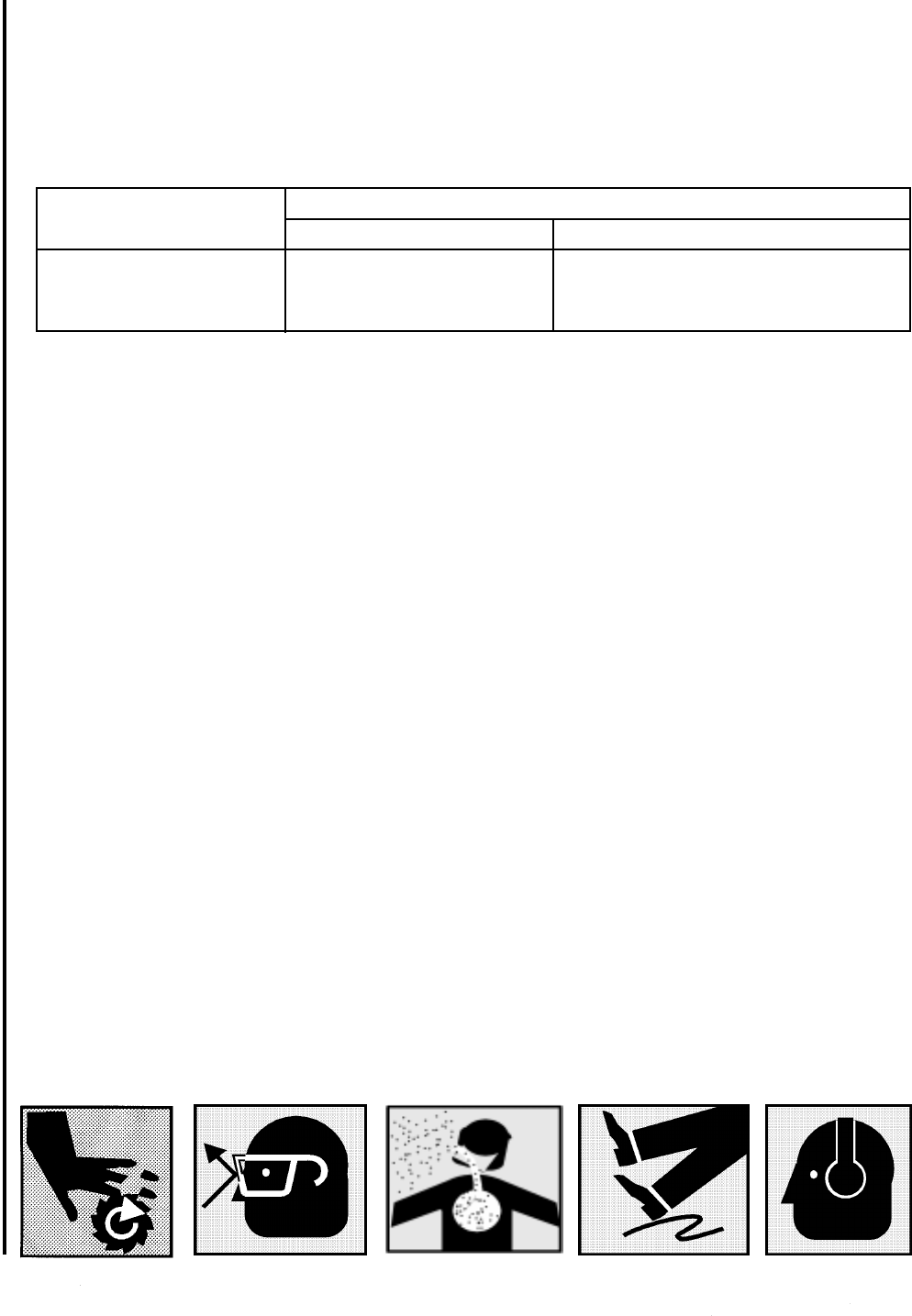

5. Keep hands in sight. Do not put hands or fingers

around, on, or below any rotating cutting tools.

Leather safety gloves should be used when handling

any sharp objects or cutting tools. See Figure A.

6. Always wear protective eye wear when operating,

servicing or adjusting machinery. Eyewear shall be

impact resistant, protective safety glasses with side

shields complying with ANSI Z87.1 specifications.

Use of the eye wear which does not comply with

ANSI Z87.1 specifications could result in severe

injury from breakage of eye protection. See Figure

B.

7. When drilling in material which causes dust, a

dust mask shall be worn. See Figure C.

8. Avoid contact with coolant, especially guarding

the eyes.

9. Non-slip footwear and safety shoes are recom-

mended. See Figure D.

10. Wear ear protectors (plugs or muffs) during

extended periods of operation. See Figure E.

Safety Instructions for Drill

Presses

1. All work shall be secured using either clamps or a

vise to the drill press table. It is unsafe to use your

hands to hold any workpiece being drilled.

2. Drill press head and table shall be securely

locked to the column before operating the drill press.

This must always be checked prior to starting the

machine.

3. Always use the correct tooling. Tooling shall

always be maintained and properly sharpened. All

tooling must be run at the proper speeds and feeds

as they apply to the job. Use only recommended

accessories and follow those manufacturers instruc-

tions pertaining to them. Tooling shall be not be

forced in to any workpiece but fed according to the

proper specifications. Failure to follow these instruc-

tions will not only ruin the tooling as well as the

machine, but can cause serious injury.

4. Never brush away any chips while the machine is

in operation. All clean up should be done when the

machine is stopped.