MACHINE OPERATIONS

LIGHTNING 86039180 05/23/07

3-3

PROPANE FUEL SYSTEM

Adjustments and repairs to the propane fuel system

can only be made by properly trained and certified

Service Technicians.

Improper adjustments will cause increased toxic

emissions of carbon monoxide and may result in

carbon monoxide poisoning.

CHANGING OIL

The manufacturer recommends 10W30 oil.

1. Run engine for 5 minutes to warm the oil.

2. Make sure machine is on level surface, pad on

the floor. Place container under drain and open

the oil drain valve. Allow oil to drain completely.

3. Close drain valve and add 1 qt. Of 10W30 motor

oil. Check level and add if necessary.

4. Replace oil-fill cap assembly. Hand tighten only.

DO NOT over fill oil and never run engine with low

oil level, this could cause damage to the engine

voiding your warranty.

NOTE: When checking oil, remove dip stick, wipe

clean, then reinsert the dip stick into the engine. DO

NOT SCREW IN (check engine manufacturer

manual for recommended procedure). Remove dip

stick and observe oil level as indicated on dip stick.

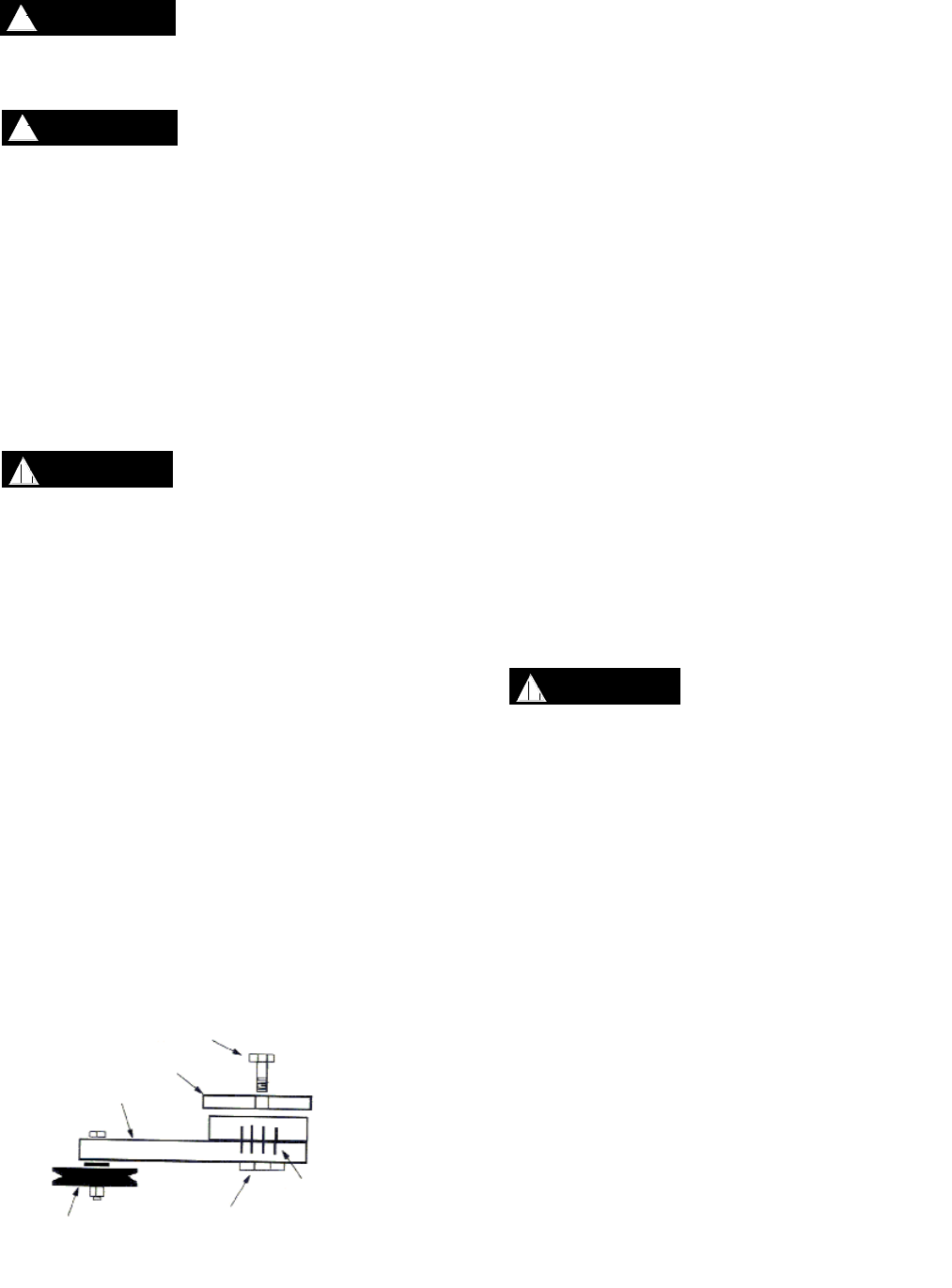

ADJUSTING BELT TENSION

Tools required for this procedure are:

- ¾” (19mm) open end wrench

- 15/16” (24mm) deep well socket

1. Loosen mounting bolt on top side of machine

deck while holding adjusting nut on underside of

deck. NOTE: the mounting bolt must be

loosened before adjustment can be made.

2. Rotate adjusting nut counter clockwise with

socket to apply tension to belt.

3. While holding the tension on the adjusting nut,

tighten the mounting bolt on top of the deck.

4. Check belt tension by pinching belt together.

Belt should depress only ½” (12mm)

REFUELING/STORING CYLINDERS

The following information refers to regulations within

the United States of America and Canada. For other

countries, the owner must assure that the required

regulations are met.

National Fire Protection Association (NFPA) has

established standards for the storage and handling

of liquefied petroleum gasses. This standard is

NFPA 58.

Liquefied propane will expand 270 times into

flammable vapor, which is used as fuel for propane

engines. Proper training is recommended for those

operating propane powered machines in order to

limit the hazards related to the handling and storage

of propane fuel cylinders.

REFUELING

The capacity of the 4E240 cylinder is 20lbs., 80% of

the total water capacity. Never overfill the cylinder.

Have the cylinder filled at a reputable propane

dealer.

Do not attempt to repair a propane cylinder yourself.

Return the cylinder to your propane dealer for

authorized service.

STORING

Propane fuel cylinders whether full or empty should

be stored outside the building in a secure cylinder

storage cabinet in accordance with NFPA 58 5-4.2.1

Vertical Propane fuel cylinders must always be

stored in a vertical position. This position assures

that the discharge from the pressure relief valve or

other items will be largely vapor and not liquid which

will expand to 270 times to flammable vapor.

The manufacturer reminds you that the fuel

cylinders should be removed from the machine

and placed in the proper storage cabinets

outside the building.

NOTE: Local authorities may have additional

requirements for storage of fuel cylinders. Always

check with the local authorities for these additional

requirements.

! WARNING

! CAUTION

! WARNING

! CAUTION

Mounting Bolt

Machine Base

Tensioner

Idler Pulley

Adjusting Nut

Tensioning Gauges