12 Owner Service

MAN0357 (Rev. 12/10/2007)

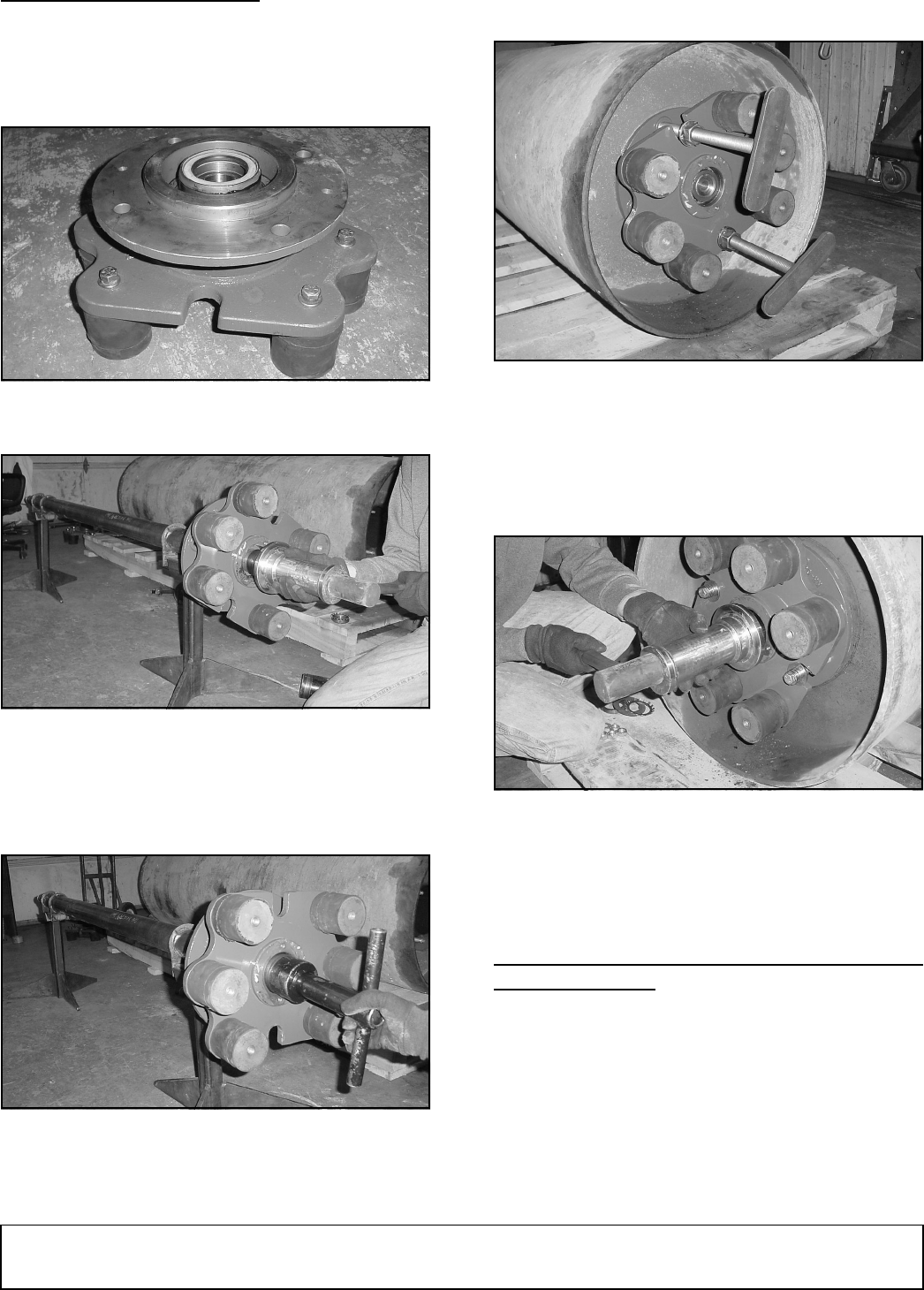

BEARING INSTALLATION

1. Apply a small amount of lubrication (oil or grease)

to the outer bearing housing.

2. Assemble the outer bearings to the inner bearings

using an industrial press.

Figure 6

3. Install one of the housing assemblies to the shaft.

Figure 7

4. Install the outside bearing cone (12).

5. Add the tongued washer, the shaft lock washer,

and the shaft nut (27, 14 & 13, using part number

1023106 socket).

Figure 8

6. Torque the nut to 15 lbs-ft. Be sure to fully engage

a tab on the shaft lock washer into a slot on the

shaft nut.

7. Insert the shaft into the drum and clamp the outer

housing to the drum.

Figure 9

8. Clamp the remaining housing assembly together

using washers and bolts in the threaded holes in

the outer housing. Be sure bolts do not protrude

through the outer housing.

9. Install this assembly onto the shaft.

Figure 10

10. Be sure the bearing is fully seated and measure

the spacing between the housing and the drum end

plate. Spacing over 1/16" must be shimmed.

11. Repeat steps 3 and 4 for this end of the drum.

HYDRAULIC MOTOR SEAL AND BEARING

REPLACEMENT

Remove Seal and Bearing

1. Disconnect hydraulic hoses from motor on the side

of the roller.

2. Remove the motor guard and the motor bolts to

remove the motor. Save hardware for later use.

3. Place motor on a suitable work area and remove

spring retaining ring securing shaft and bearing in

the motor housing. Save retaining ring for later use.