7 8

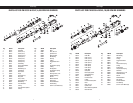

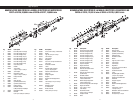

PARTS LIST FOR PN 28331 & 28346, Extended 18,000 RPM DIE GRINDERS

PartsPage

*Declarednoiselevels;measurementscarriedoutinaccordancewithstandardENISO15744:2002.

**DeclaredvibrationlevelsinaccordancewithEN12096;measurementscarriedoutinaccordancewithstandardENISO8662-13:1997.

IMPORTANTNOTE:Thenoiseandvibrationvaluesstatedinthetablearefromlaboratorytestinginconformitywithstatedcodesandstandardsandarenot

sufcientriskevaluationforallexposurescenarios.Theactualexposurevaluesandamountofriskorharmexperiencedtoanindividualisuniquetoeach

situationanddependsuponthesurroundingenvironment,thewayinwhichtheindividualworks,theparticularmaterialbeingworked,workstationdesign,as

wellasupontheexposuretimeandthephysicalconditionoftheuser.3Mcannotbeheldresponsiblefortheconsequencesofusingdeclaredvaluesinsteadof

actualexposurevaluesforanyindividualriskassessment.

PRIORTOTHEOPERATION

Thetoolisintendedtobeoperatedasahandheldtool.Itisalwaysrecommendedthatwhileusingthetool,operatorsstandonasolidoor,inasecureposition

witharmgripandfooting.Beawarethatthesandercandevelopatorquereaction.SeethesectioninSAFETYPRECAUTIONSin.

Useacleanlubricatedairsupplythatwillgiveameasuredairpressureatthetoolof6.2bar(90psig)whenthetoolisrunningwiththeleverfullydepressed.Itis

recommendedtouseanapproved10mm(3/8in)x8m(25ft)maximumlengthairline.ConnectthetooltotheairsupplyasshowninFigure1.Donotconnect

thetooltotheairlinesystemwithoutaneasilyaccessibleairshutoffvalve.Itisstronglyrecommendedthatanairlter,regulatorandlubricator(FRL)beused

asshowninFigure1asthiswillsupplyclean,lubricatedairatthecorrectpressuretothetool.Inanycaseappropriateairpressureregulatorsshallbeusedat

alltimeswhileoperatingthistoolwherethesupplypressureexceedsthemarkedmaximumofthetool.Detailsofsuchequipmentcanbeobtainedforyourtool

distributor.Ifsuchequipmentisnotused,thetoolshouldbemanuallylubricated.Tomanuallylubricatethetool,disconnecttheairlineandput2to3dropsof

suitablepneumaticmotorlubricatingoilsuchas3M™AirToolLubricantPN20451,FujiKosanFK-20orMobilALMO525intothehoseend(inlet)ofthetool.

Reconnecttooltotheairsupplyandruntoolslowlyforafewsecondstoallowairtocirculatetheoil.Ifthetoolisusedfrequently,lubricateitonadailybasisor

lubricateitifthetoolstartstosloworlosepower.Itisrecommendedthattheairpressureatthetoolbe6.2bar(90psig)whilethetoolisrunningsothemaximum

RPMisnotexceeded.Thetoolcanberunatlowerpressuresbutshouldneverberunhigherthan6.2bar(90psig).Ifrunatlowerpressuretheperformanceofthe

toolisreduced.

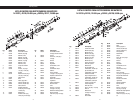

ProductConguration/Specications

Operating/MaintenanceInstructions

Model Number Collet Speed RPM

Product Net

Wt kg

(lb)

Height

mm (in)

Length mm

(in)

*Noise Lever

dBA Pressure

(Power)

**Vibration

Level m/s

2

(ft/s

2

)

**Uncertainty

K m/s

2

20237

25126

1/4in

6mm

20,000

0.77(1.69)

0.77(1.69)

76.2(3)

76.2(3)

196(7.5)

196(7.5)

83.5(95.1)

83.5(95.1)

<2.5(<8.2)

<2.5(<8.2)

NA

NA

20238

25127

1/4in

6mm

18,000

0.77(1.69)

0.77(1.69)

76.2(3)

76.2(3)

196(7.5)

196(7.5)

83.5(95.1)

83.5(95.1)

<2.5(<8.2)

<2.5(<8.2)

NA

NA

20239

25128

1/4in

6mm

12,000

0.93(2.06)

0.93(2.06)

81.2(3.2)

81.2(3.2)

254(10)

254(10)

83.5(95.1)

83.5(95.1)

3.62(11.9)

3.62(11.9)

1.81

1.81

20240

25129

1/4in

6mm

8,000

0.93(2.06)

0.93(2.06)

81.2(3.2)

76.2(3.2)

254(10)

254(10)

83.5(95.1)

83.5(95.1)

3.62(11.9)

3.62(11.9)

1.81

1.81

28332

28347

1/4in

6mm

4,000

0.717(1.58)

0.717(1.58)

69.9(2.75)

69.9(2.75)

200(8.875)

200(8.875)

87.0(98.6)

87.0(98.6)

5.52

5.52

0.732

0.732

28330

28345

1/4in

6mm

18,000

0.512(1.13)

0.512(1.13)

69.9(2.75)

69.9(2.75)

174.6(6.875)

174.6(6.875)

87.0(98.6)

83.5(95.1)

1.91

1.91

NA

NA

28331

28346

1/4in

6mm

18,000

0.697(1.54)

0.697(1.54)

69.9(2.75)

69.9(2.75)

269.9(10.625)

269.9(10.625)

87.0(98.6)

87.0(98.6)

2.53

2.53

0.295

0.295

RecommendedAirline

Size-Minimum

10mm3/8in

RecommendedMaximumHoseLength

8meters25feet

AirPressure

MaximumWorkingPressure6.2bar90psig

RecommendedMinimumN/AN/A

Fig. 3M PN Description

1 06572 ColletNut

2 06575 Collet(1/4in)

2 06573 Collet(1/8in)

2 06574 Collet(3/16in)

2 06545 Collet(3/8in)

2 06576 Collet(3mm)

2 06577 Collet(6mm)

2 06546 Collet(8mm)

3 30371 ColletBody

4 06611 BallBearing(3)

5 30420 ClampNut

6 30421 ExtensionShaft

7 30423 Pilot(.75ID)

8 30392 SpringWasher(2)

9 06629 FrontEndPlate

10 06621 O-Ring

11 30418 FrontEndPlateSpacer

12 30422 Rotor

13 06647 Vane,Setof4

14 06631 CylinderLiner

15 30373 MotorRestrictingWasher

Fig. 3M PN Description

16 06630 RearEndPlate

17 06612 BallBearing

18 06625 Housing

19 30400 O-Ring

20 06626 TriggerValveStem

21 06616 Pin

22 06614 CompressionSpring

23 06620 O-Ring

24 06627 AirRegulator

25 06613 CompressionSpring

26 06622 SteelBall

27 06599 HousingCover,.5HP

28 06635 PaddleAssembly

29 06617 RollPin

30 06632 MuferMaterial

31 06615 DiscSpring

32 06628 ExhaustDeector

33 06618 InletBushing

34 06569 9/16inx3/4inWrench(2)