If you have any questions, call 1-800-54-HOW-TO

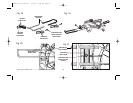

BEVEL POINTERS

If the bevel pointers (11) do not indicate zero, loosen the screw that

holds it in place and move the pointer as necessary.

FENCE ADJUSTMENT

Turn Off and Unplug the Miter Saw

In order that the saw can bevel to a full 47 degrees left, the left side of

the fence can be adjusted to the left to provide clearance. To adjust

the fence, loosen the two plastic knobs (7) shown in Figure 1 and

slide the fence to the left. Make a dry run with the saw turned off and

check for clearance. Adjust the fence to be as close to the blade as

practical to provide maximum workpiece support, without interfering

with arm up & down movement. Tighten both knobs securely. When

the bevel operations are complete, don’t forget to relocate the fence to

the right.

NOTE: The guide groove in the left side fence (7) can become

clogged with sawdust. If you notice that it is becoming clogged, use a

stick or some low pressure air to clear the guide groove.

GUARD ACTUATION AND VISIBILITY

The blade guard on your saw has been designed to automatically

raise when the arm is brought down and to lower over the blade when

the arm is raised.

The guard can be raised by hand when installing or removing saw

blades or for inspection of the saw. NEVER RAISE THE BLADE

GUARD MANUALLY UNLESS THE SAW IS TURNED OFF.

NOTE: Certain special cuts will require that you manually raise the

guard. To do this, simply place your right thumb on the upper side of

the guard and roll the guard up just enough to clear the workpiece.

Never tie up or otherwise prevent the guard from operating normally.

The front section of the guard is louvered for visibility while cutting.

the two screws. Pay no attention to the reading of the miter pointer at

this point.

MITER POINTER ADJUSTMENT

Loosen the miter clamp handle (4) and squeeze the miter latch (5) to

move the miter arm to the zero position. With the miter clamp handle

loose allow the miter latch to snap into place as you rotate the miter

arm past zero. Observe the pointer and miter scale (6) through the

miter latch opening. If the pointer does not indicate exactly zero,

loosen screw and re-align the pointer.

BEVEL STOP ADJUSTMENT

Loosen the bevel clamp knob (10) and move the cutting arm all the

way to the right, then tighten the bevel clamp knob. Using a square,

place one end of the square on the table and the other end against

the blade. Check to see if the blade is at 90 degrees to the table. If an

adjustment is necessary loosen the locknut below the right side bevel

stop (13) and turn the screw until it contacts the casting when the

blade is at 90 degrees. Then tighten locknut. To set the 45 degree

bevel stop (opposite side), first loosen the left side fence clamping

knobs (7) and slide the left side fence as far as it will go to the left.

Loosen bevel clamp knob (10) and move the cutting arm all the way

to the left bevel position and tighten bevel clamp knob. Using a

combination square check to see that blade is at 45 degrees to the

table as shown in Figure 9. If an adjustment is necessary, loosen the

locknut on the left side of the casting and turn screw until it contacts

casting when blade is at 45 degrees. Then tighten locknut.

To achieve 2 degree right bevel or 47 degree left bevel, the stop

screws must be adjusted to allow the arm to move to the desired

location. The bevel stops will need readjustment to the zero and 45

degree positions after cuts are made.

13

395136-00,03,BT1500 6/22/04 9:05 AM Page 13