USE OF EXTENSION CORDS

Make sure the extension cord is in good condition before using. Always use the proper size

extension cords with the tool – that is, proper wire size for various lengths of cord and heavy

enough to carry the current the tool will draw. Use of an undersized cord will cause a drop

in line voltage resulting in loss of power and overheating. For proper size cords see chart

below.

MOTOR

Be sure your power supply agrees with nameplate marking. 120 Volts AC only means your

tool will operate on standard 60 Hz household power. Do not operate AC tools on DC. A

rating of 120 volts AC/DC means that you tool will operate on standard 60 Hz AC or DC

power. This information is printed on the nameplate. Lower voltage will cause loss of power

and can result in over-heating. All Black & Decker tools are factory-tested; if this tool does

not operate, check the power supply.

SAVE THESE INSTRUCTIONS

Assembly/Adjustment Set-up

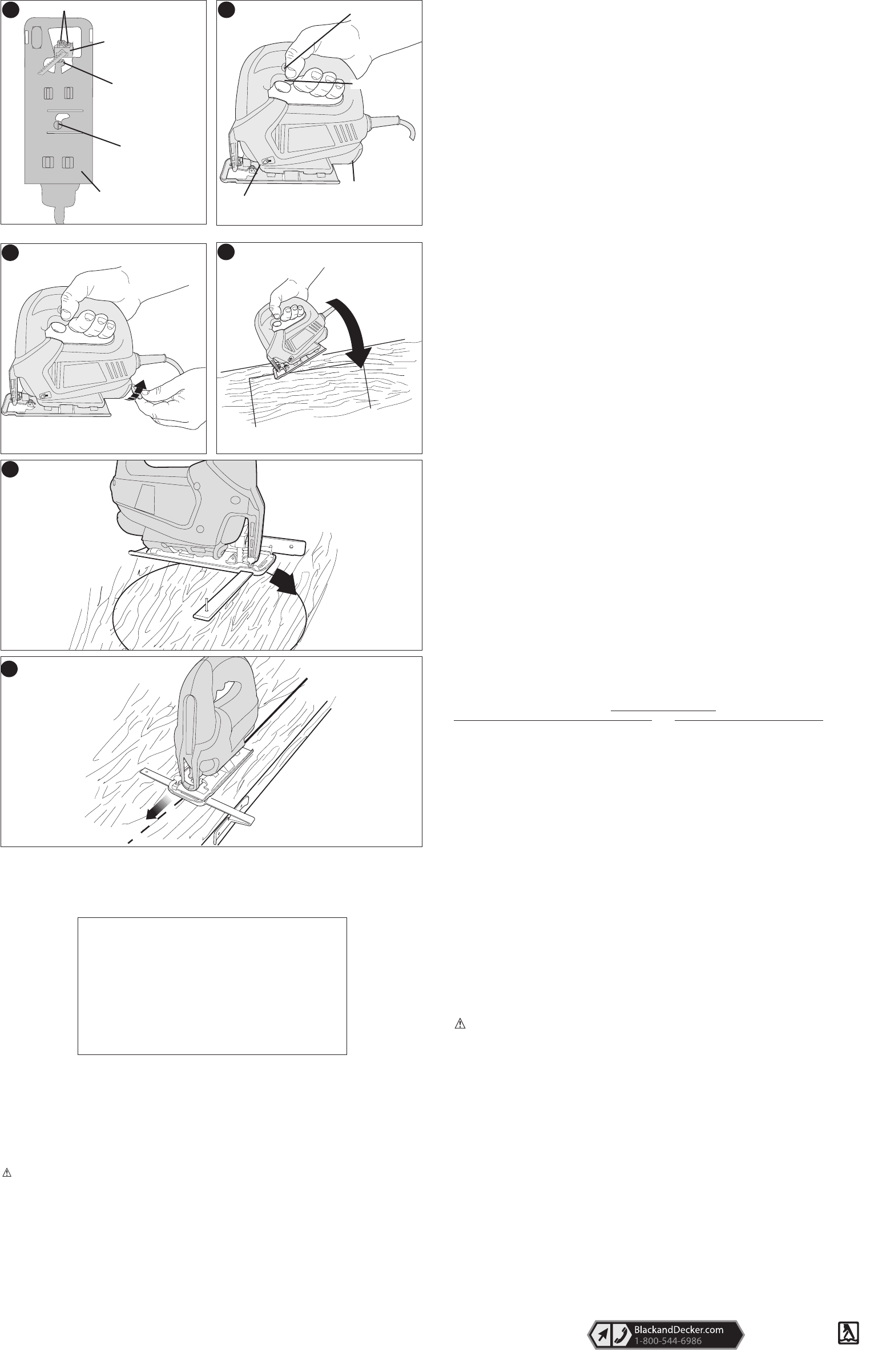

INSTALLING BLADES

WARNING: Before attempting any of the following operations, make sure that the tool is

switched off and unplugged and that the saw blade has stopped. Used saw blades can be

hot.

Using a flat blade screwdriver, loosen (do not remove) the two screws “A” in Figure B.

Ensure the blade teeth are facing forward and insert the saw blade shank fully into the blade

clamp. Slightly tighten screws alternately to position the blade, then fully tighten screws. To

release, turn both screws one turn counterclockwise.

Note: To improve cutting performance, ensure back of blade is touching blade support

roller. See “Roller Support Guide”for instructions on how to change position of blade support

roller.

BLADE SUPPORT ROLLER

TURN OFF AND UNPLUG TOOL.

The blade support roller on your jigsaw improves its performance when cutting tough

materials by adding support to the blade. This support should be adjusted so that the roller

touches the back of the blade when cutting. Ensure the blade is aligned with the groove in

the roller. Adjust the support roller by loosening the screw on the bottom of the shoe (Fig.B)

and moving the shoe so that the roller touches the back edge of the blade. Retighten screw.

Lubricating the guide roller from time to time with a drop of oil will extend the life of the roller.

NOTE: Roller support guide not applicable when shoe is beveled to 45 degrees.

Minimum Gauge for Cord Sets

Volts Total Length of Cord in Feet

120V 0-25 26-50 51-100 101-150

(0-7,6m) (7,6-15,2m) (15,2-30,4m) (30,4-45,7m)

240V 0-50 51-100 101-200 201-300

(0-15,2m) (15,2-30,4m) (30,4-60,9m) (60,9-91,4m)

Ampere Rating

More Not more American Wire Gauge

Than Than

0 - 6 18 16 16 14

6 - 10 18 16 14 12

10 - 12 16 16 14 12

12 - 16 14 12 Not Recommended

ON/OFF SWITCH

BEFORE PLUGGING YOUR JIGSAW IN, ENSURE THAT THE TRIGGER SWITCH IS IN

THE OFF POSITION.

To turn the saw on, squeeze the trigger switch, as shown in Figure C. To turn the tool

off, release the trigger switch. The tool can be locked on for continuous operation by fully

squeezing and holding the trigger switch while you depress the lock-on button shown in

Fig. C. With the lock-on button depressed, release the trigger switch and the tool will

continue to run. To release from lock position, squeeze and release the trigger. Always

disengage the lock before disconnecting from the power supply.

BEVEL ADJUSTMENT

TURN OFF AND UNPLUG TOOL.

To adjust the bevel angle, loosen the screw (approximately 3 full turns) on the bottom of

the shoe, as shown in Figure B. Lift the shoe slightly and pull backward, then set the shoe

at 45° (accuracy +/-5°) and retighten screw. To reset the shoe for a square cut, loosen the

screw and move the shoe until it is approximately 90° to the blade. Adjust the blade support

roller to the blade and retighten the screw.

GENERAL CUTTING

Be sure board is firmly secured. Hold jigsaw by the handle and operate switch to turn the

unit on. Don’t attempt to turn on the unit when blade is against material to be cut. This

could stall the motor. Place front of shoe on material to be cut and hold jigsaw shoe down

firmly against the work surface while cutting. Don’t force the tool; let the blade cut at its own

speed. Whenever possible, clamp or support work close to the line of cut; when the cut is

completed, shut off power and lay the saw aside before loosening the work.

AUTOMATIC DUST BLOWER

To aid visibility when cutting, your jigsaw is equipped with an automatic dust blower (Fig. C)

which will keep the work area clear of dust as you saw.

BLADE STORAGE

A convenient blade storage compartment (Fig. D) is provided at the rear of the saw.

METAL & PLASTIC CUTTING

In cutting thin gauge sheet metals, it is best to clamp wood or plywood to the bottom of the

metal sheet; this will insure a clean cut without the danger of vibration or tearing of metal.

Use a fine-tooth blade for ferrous metals (for those that have an iron content); and use a

coarser blade for nonferrous metals (those that do not have an iron content).

Cutting thin metal will take longer than cutting relatively thick wood so do not be tempted

to speed up the process by forcing the saw. Spread a thin film of cutting lubricant along the

cutting line (any light weight oil).

When cutting laminated plastic, place the finished side down and use a fine tooth hollow

ground blade.

POCKET CUTTING

• Measurethesurfacetobecutandmarkclearlywithapencil.Nexttipthesawforward

until the front edge of the shoe sits firmly on the work surface, but with the blade well

clear of it Figure E.

• Turnthetoolonandallowittoattainmaximumspeedbyfullydepressingthetriggerswitch.

• Gripthehandlefirmlyandslowlylowerthebackedgeoftooluntilthebladecuts

smoothly into material. Do not move the jigsaw forward along the cut line until the saw

blade has completely entered the material and shoe comes to rest flat on its surface.

RIP & CIRCLE CUTTING

Ripping and circle cutting without a pencil line are easily done with the rip fence and circle

guide (available at extra cost).

Using the screw supplied with the accessory guide, position as shown in Figure F and thread

the screw into the shoe to clamp the fence securely.

When circle cutting, adjust rip fence so that distance from blade to hole in cross bar is at

the desired radius and tighten screw (use hole which lines up best with saw blade). Place

saw so that hole in cross bar is over center of circle to be cut (make pocket cut, drill hole for

blade or cut inward from edge of material to get blade into position). When saw is properly

positioned, drive a small nail through hole in cross bar. Using rip fence as a pivot arm, begin

cutting circle. For circle cutting, the cross bar should be up, as shown in Figure F.

When ripping, slide the rip fence under the screw from either side of the saw. Set the cross

bar at desired distance from blade and tighten screw. For ripping, the cross bar should be

down and against the straight edge of the workpiece.

MAINTENANCE

Use only mild soap and damp cloth to clean the tool. Never let any liquid get inside the tool;

never immerse any part of the tool into a liquid.

IMPORTANT: To assure product SAFETY and RELIABILITY, repairs, maintenance and

adjustment should be performed by authorized service centers or other qualified service

organizations, always using identical replacement parts.

TROUBLESHOOTING

Problem Possible Cause Possible Solution

• Unitwillnotstart. •Cordnotpluggedin. •Plugtoolintoaworking

outlet.

•Circuitfuseisblown. •Replacecircuitfuse.

(If the product repeatedly

causes the circuit fuse to

blow, discontinue use

immediately and have it

serviced at a Black &

Decker service center or

authorized servicer.)

•Circuitbreakeristripped. •Resetcircuitbreaker.

(If the product repeatedly

causes the circuit breaker

to trip, discontinue use

immediately and have it

serviced at a Black &

Decker service center or

authorized servicer.)

•Cordorswitchisdamaged. •Havecordorswitch

replaced at Black &

Decker Service Center or

Authorized Servicer.

For assistance with your product, visit our website www.blackanddecker.com for the loca-

tion of the service center nearest you or call the BLACK & DECKER help line at

1-800-544-6986.

ACCESSORIES

Recommended accessories for use with your tool are available from your local dealer or

authorized service center. If you need assistance regarding accessories, please call:

1-800-544-6986

WARNING: The use of any accessory not recommended for use with this tool could be

hazardous.

SERVICE INFORMATION

Black & Decker offers a full network of company-owned and authorized service locations

throughout North America. All Black & Decker Service Centers are staffed with trained

personnel to provide customers with efficient and reliable power tool service. Whether you

need technical advice, repair, or genuine factory replacement parts, contact the

Black & Decker location nearest you. To find your local service location, refer to the yellow

page directory under “Tools—Electric” or call: 1-800-544-6986.

FULL TWO-YEAR HOME USE WARRANTY

Black & Decker (U.S.) Inc. warrants this product for two years against any defects in

material or workmanship. The defective product will be replaced or repaired at no charge in

either of two ways.

The first, which will result in exchanges only, is to return the product to the retailer from

whom it was purchased (provided that the store is a participating retailer). Returns should

be made within the time period of the retailer’s policy for exchanges (usually 30 to 90 days

after the sale). Proof of purchase may be required. Please check with the retailer for their

specific return policy regarding returns that are beyond the time set for exchanges.

The second option is to take or send the product (prepaid) to a Black & Decker owned

or authorized Service Center for repair or replacement at our option. Proof of purchase

may be required. Black & Decker owned and authorized Service Centers are listed under

“Tools–Electric” in the yellow pages of the phone directory.

This warranty does not apply to accessories. This warranty gives you specific legal rights

and you may have other rights which vary from state to state. Should you have any

questions, contact the manager of your nearest Black & Decker Service Center. This

product is not intended for commercial use.

Free warning label replacement: If your warning labels become illegible or are missing,

call 1-800-544-6986 for a free replacement.

F

G

E

D

B

C

BLADE CLAMP

ROLLER SUPPORT

GUIDE

A

SHOE

SCREW

TRIGGER SWITCH

LOCK ON BUTTON

BLADE STORAGE

DUST BLOWER

See ‘Tools-

Electric’

– Yellow Pages –

for Service &

Sales

Imported by

Black & Decker (U.S.) Inc.,

701 E. Joppa Rd.

Towson, MD 21286 U.S.A.