15

Performing repairs may expose voltage sources, moving parts or

compressed air sources, personal injury may occur. Maintenance

other than that recommended in the “Troubleshooting” section of this manual is

not recommended and should be performed by trained service personnel.

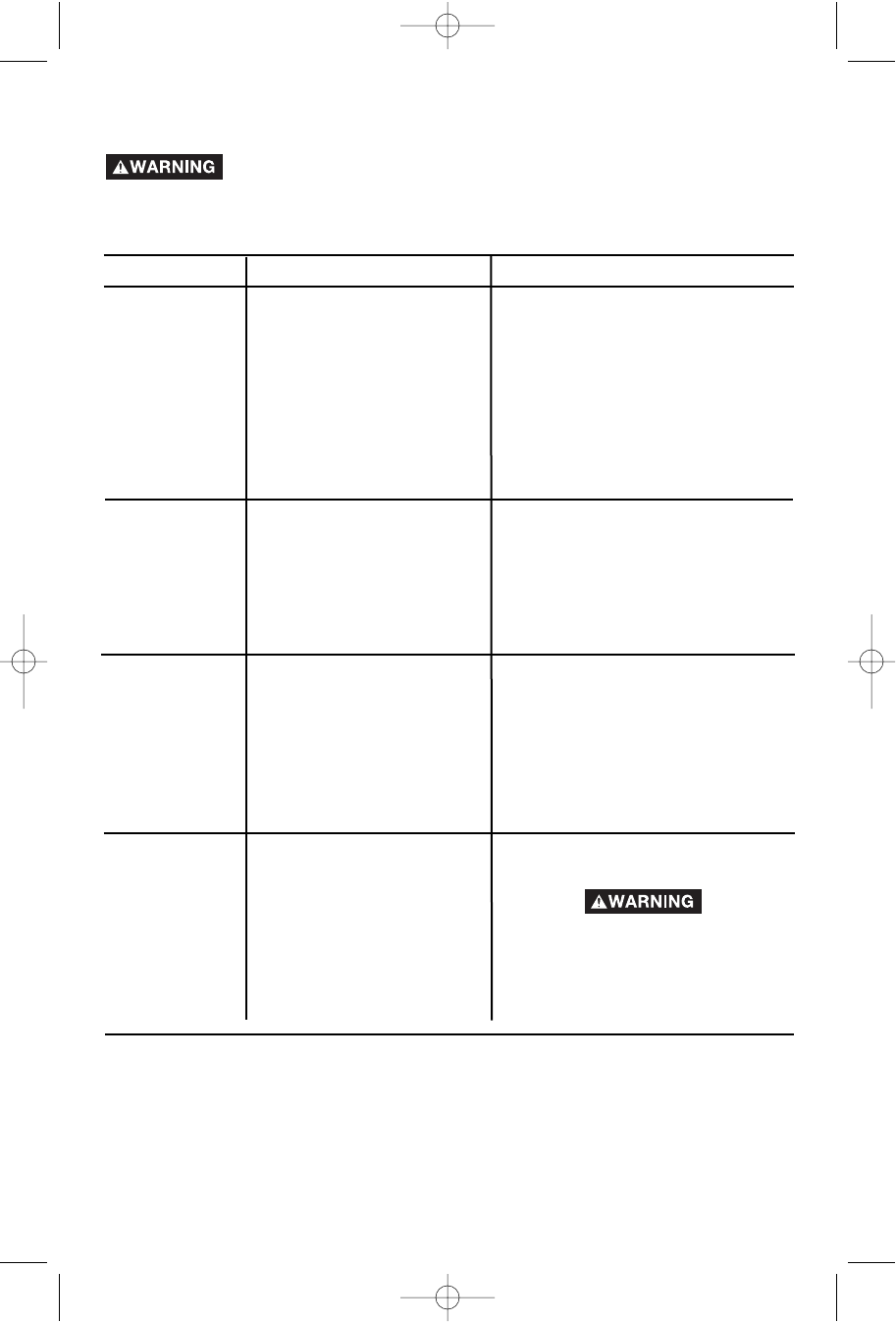

PROBLEM

CAUSE

CORRECTION

Compressor does not turn

off when compressor

reaches "cut-out" pressure.

Pressure switch "cut-out"

too high.

Set Auto/On/Off switch to the "OFF"

position, if the unit does not shut

off contact a Trained Service

Technician.

Contact a Trained Service

Technician.

Excessive tank

pressure - safety

valve pops off.

Tube fittings are not tight

enough.

Using a soapy water solution check

all exposed fittings for leaks. If

needed reseal fittings with pipe

sealant tape and retighten securely.

Do Not Overtighten. If leaks

continue contact a Trained Service

Technician.

Air leaks at

fittings.

Air leaks in air

tank or at air

tank welds.

Defective air tank.

Air tank must be replaced. Do not

repair the leak.

Do not drill into, weld or

otherwise modify air tank or it

will weaken. The tank can rupture

or explode.

TROUBLESHOOTING

Low voltage. Extension cord is wrong length or

gauge. Check extension cord.

Thermal

overload

protector cuts

out repeatedly.

Improper ventilation/

temperature too high.

Operate compressor in a well

ventilated area.

Defective check valve.

Contact a Trained Service

Technician.

Defective valves.

Contact a Trained Service

Technician.

495233-00, BDCP200 Compressor 8/1/06 10:14 AM Page 15