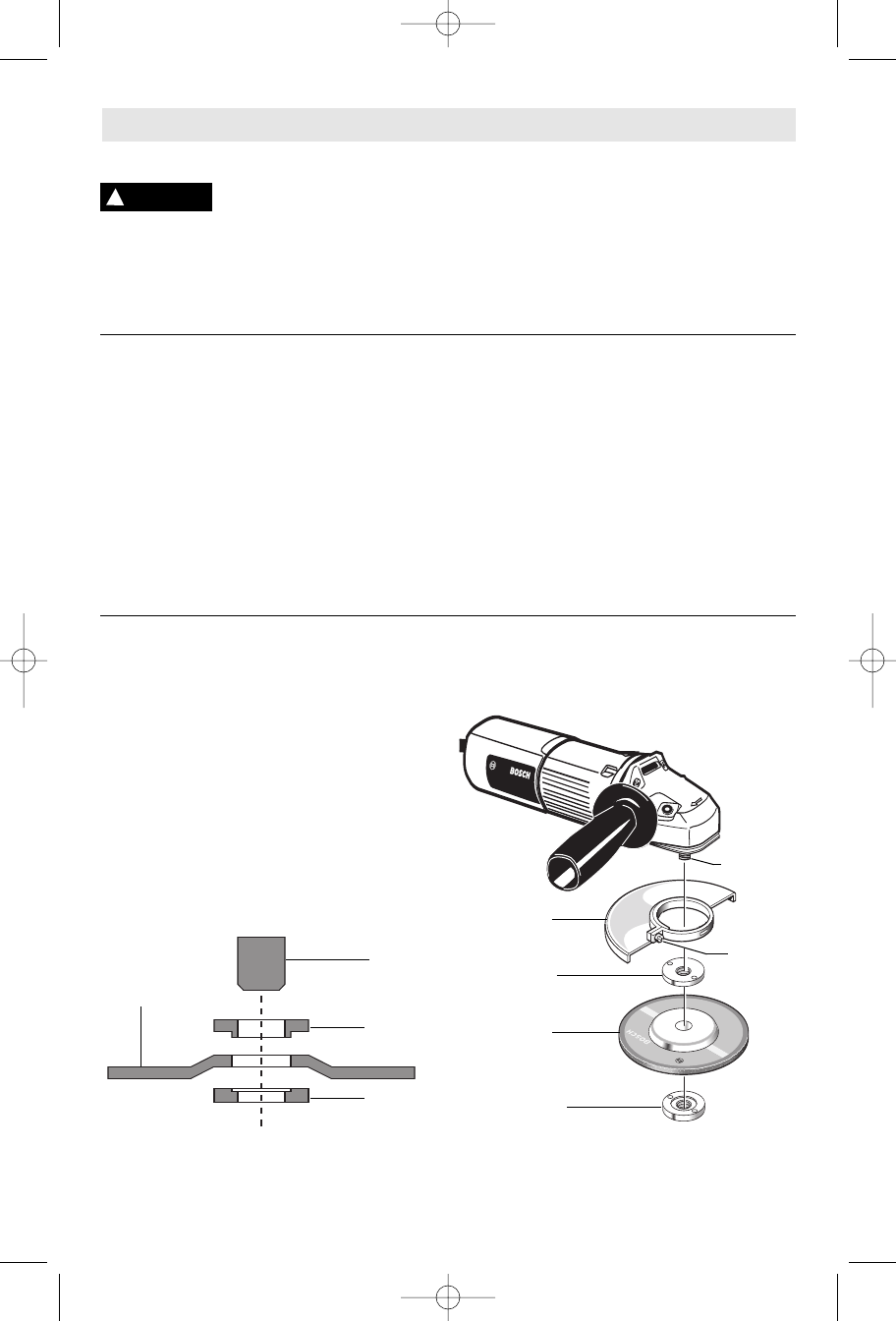

Disc Grinding Wheel Assembly

Disconnect tool from power source. Be sure

that wheel guard is in place for grinding.

Thread BACKING FLANGE onto spindle,

then place GRINDING WHEEL on the

spindle. Thread on the lock nut and tighten

nut using the supplied lock nut wrench, while

holding the spindle lock in.

TO REMOVE: Reverse procedure.

W

HEEL GUARD INSTALLATION

Wheel guard must be

attached when using disc

grinding wheels. Always keep wheel guard

between you and your work while grinding.

T

o attach the wheel guard DISCONNECT

tool from power source.

Position the guard on spindle neck, then

secure guard with the collar screw.

Assembly

-7-

LOCK NUT AND BACKING FLANGE

Your tool is equipped with a threaded spindle

for mounting accessories. Always use the

supplied lock nut (and backing flange) that

has same thread size as spindle.

SIDE HANDLE

The side handle used to guide and balance the

tool can be threaded into the front housing on

either side of the tool, depending on personal

preference and comfort. Use the side handle

for safe control and ease of operation.

!

WARNING

LOCK NUT

GRINDING

WHEEL

BACKING

FLANGE

SPINDLE

LOCK NUT

GRINDING

WHEEL

BACKING

FLANGE

COLLAR

SCREW

WHEEL

GUARD

SPINDLE

BM F000622188 12-04 12/10/04 9:27 PM Page 7