Operating Instructions

-9-

PLUNGER SPEED

The jigsaw cutting speed or stroke rate

required depends on the material being cut,

the type of blade being used, and the feed

rate preferred by the operator.

The best speed for a particular application is

largely determined by experience though as a

general rule, slower speeds are for denser

materials and faster speeds for softer

materials.

Note that when the jigsaw is used at low

speed settings for an extended length of time,

the motor temperature will rise due to slower

speeds of the internal cooling fan. In such

cases, it is necessary to occasionally run the

tool at full speed for a few minutes to keep

the motor running at high efficiency.

TRIGGER SWITCH WITH "LOCK-ON" BUTTON

(Model 1590EVS only)

Your jigsaw can be turned "ON" or "OFF" by

squeezing or releasing the trigger. Your jigsaw

is also equipped with a "Lock-ON" button

located just above the trigger that allows

continuous operation without holding the

trigger (Fig. 1).

TO LOCK SWITCH ON: Squeeze trigger fully,

depress button and release trigger.

TO UNLOCK THE SWITCH: Squeeze trigger

and release it without depressing the "Lock-

ON" button.

If the "Lock-ON" button is

continuously being de-

pressed, the trigger cannot be released.

SLIDE ON-OFF SWITCH

(Model 1591EVS only)

The tool is switched “ON” by the switch

button located at the side of the motor

housing. The switch locks in the “ON”

position, a convenience for continuous

operation (Fig. 1).

TO TURN THE TOOL “ON” slide the switch

button forward.

TO UNLOCK THE SWITCH, slide the switch

button backward.

CONSTANT RESPONSE CIRCUITRY

The internal electronic feedback system

provides a "soft start", which will reduce the

stresses that occur from a high torque start.

The system also maintains the selected

speed under load for maximum efficiency.

VARIABLE SPEED DIAL

Your Jigsaw is equipped with a variable speed

dial. The blade stroke rate may be adjusted

during cutting operation by presetting the dial

on or between any one of the six numbers.

Setting SPM rating (strokes per minute)

1 500

2 500-800

3 500-1400

4 500-1900

5 500-2400

6 500-2800

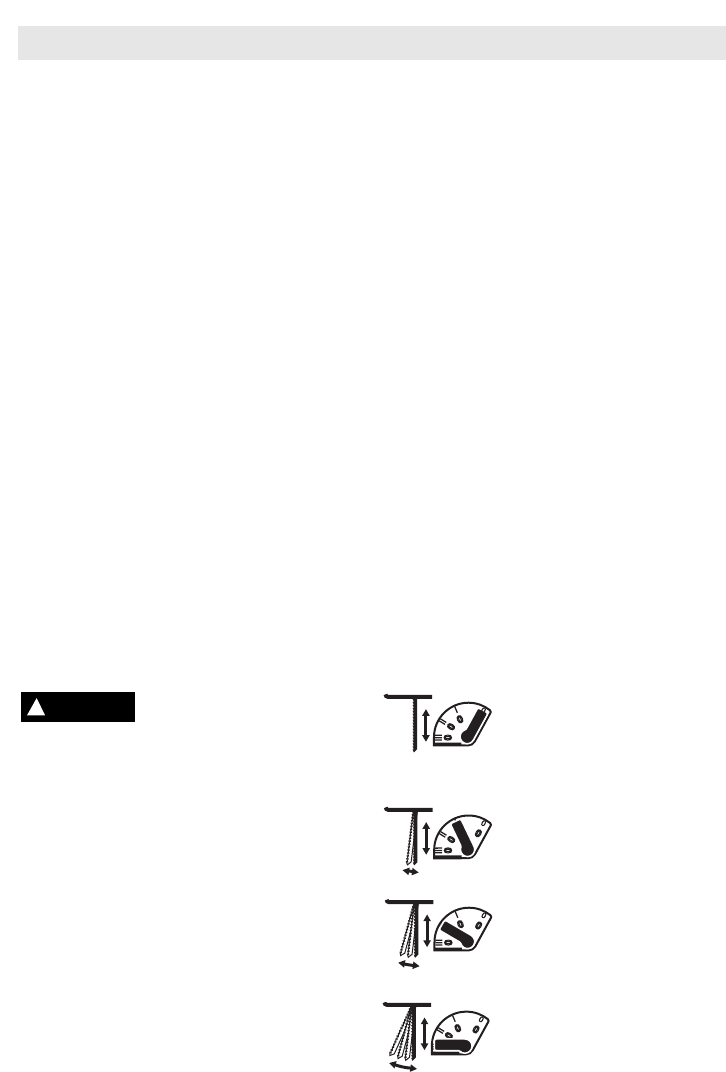

BLADE ORBIT SELECTOR LEVER

Maximum cutting efficiency can be obtained

by adjusting the blade orbit selector lever to

suit the material being cut.

The following chart will help you determine

which setting to use for your application.

This chart is intended as a guideline only,

and test cuts in scrap material should be

performed first to determine the best setting.

Setting O

Hard materials such as

metals or thin sheet metals.

This setting can be used

with knife blades, grit edge

blades, rasp work and down

cutting blades.

Setting 1

Soft materials where cleaner

cutting or delicate scrolling

work is performed.

Setting 2

Medium density materials

such as harder woods or

particle board.

Setting 3

Soft materials such as wood,

plastics, etc. and when fast

cutting is more important

than a clean cut.

!

WARNING