P

age 11

Set the speed indicator to fit the job; to achieve the

best job results when working with different mate-

rials, the speed of the Rotary Tool should be regu-

lated. Only a full wave output speed control such as

the Dremel Model 221 should be used with the

275T6 Rotary Tool.

To select the right speed for each job, use a practice

piece of material. Vary speed to find the best speed

for the accessory you are using and the job to be

done.

NOTE: Speed is affected by voltage changes. A

reduced incoming voltage will slow the RPM of the

tool, especially at the lowest setting. If your tool

appears to be running slowly increase the speed

setting accordingly. The tool may not start at switch

position #1 in those areas where outlet voltage is

less than 120 volts. Simply move the switch lever to

a higher position to begin operation.

There are three basic types of Rotary Tools: single

speed, two-speed and variable speed models.

On the single speed model, there is an ON-OFF

switch. When the switch is on, the tool runs at 35,000

RPM.

On the two-speed model, there is a LO and HI switch.

When the switch indicator is on the low setting, the

tool runs at about 15,000 RPM. When the switch

indicator is on the high setting, the tool runs at about

35,000 RPM.

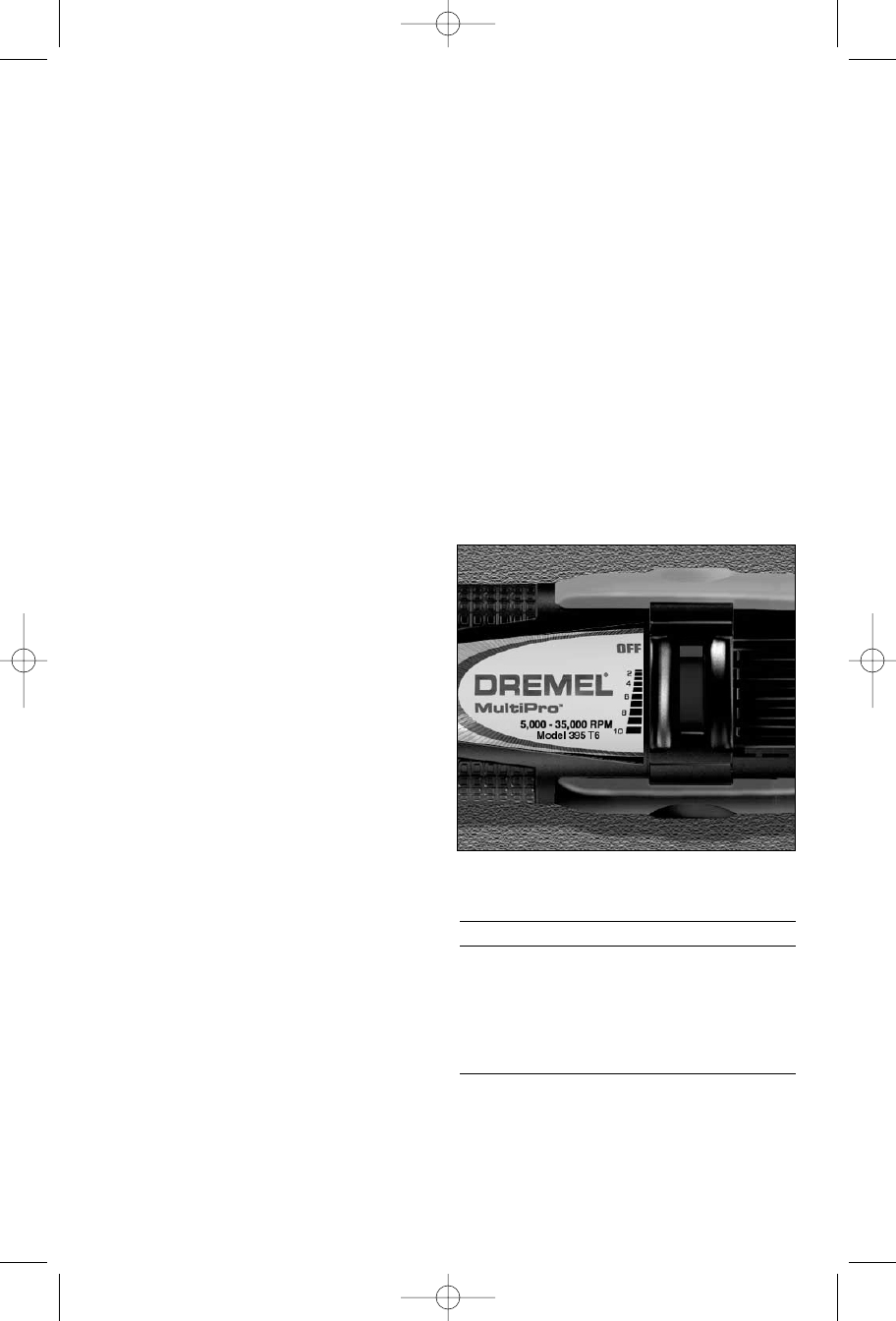

On the variable speed model, there are switch setting

indicators marked with a line. Slide to the number on

the housing to select the operating speed needed

from 5,000 – 35,000 RPM.

You can refer to the

charts on page 24, 25, and 26 to determine the

proper speed, based on the material being worked

and the type of accessory being used. These charts

enable you to select both the correct accessory and

the optimum speed at a glance.

If you have a single-speed or two-speed model, you

will be able to use many accessories to do a wide

assortment of jobs. For the majority of applications,

all models of the Rotary Tool should be used at top

speed.

Needs for Slower Speeds

Certain materials, however, (some plastics and

precious metals, for example) require a relatively slow

speed because at high speed the friction of the

accessory generates heat and may cause damage to

the material.

Slow speeds (15,000 RPM or less) usually are best

for polishing operations employing the felt polishing

accessories. They may also be best for working on

delicate projects as “eggery” work, delicate wood

carving and fragile model parts. (All brushing

applications require lower speeds to avoid wire

discharge from the holder.) No greater than speed

setting 4 for the model 395-T6.

Higher speeds are better for carving, cutting, routing,

shaping, cutting dadoes or rabbets in wood.

Hardwoods, metals and glass require high speed

operation, and drilling should also be done at high

speeds.

The speed of Rotary Tool is controlled by setting

this indicator on the housing.

The Settings for Approximate Revolutions Per Min-

ute Rotary Tool Variable Speed Model 395T6.

Switch Setting Speed Range

2 15,000 – 18,000 RPM

4* 19,000 – 11,000 RPM

6

12,000 – 17,000 RPM

8 18,000 – 24,000 RPM

10 25,000 – 35,000 RPM

* 395-T6 Wire Brush Setting.

Use only Dremel Tested, High Performance Accessories.

Operating Speeds

DM 2610925474 10-04 10/19/04 3:40 PM Page 11